- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

TP-033

TOPLIFT

| Availability: | |

|---|---|

| Quantity: | |

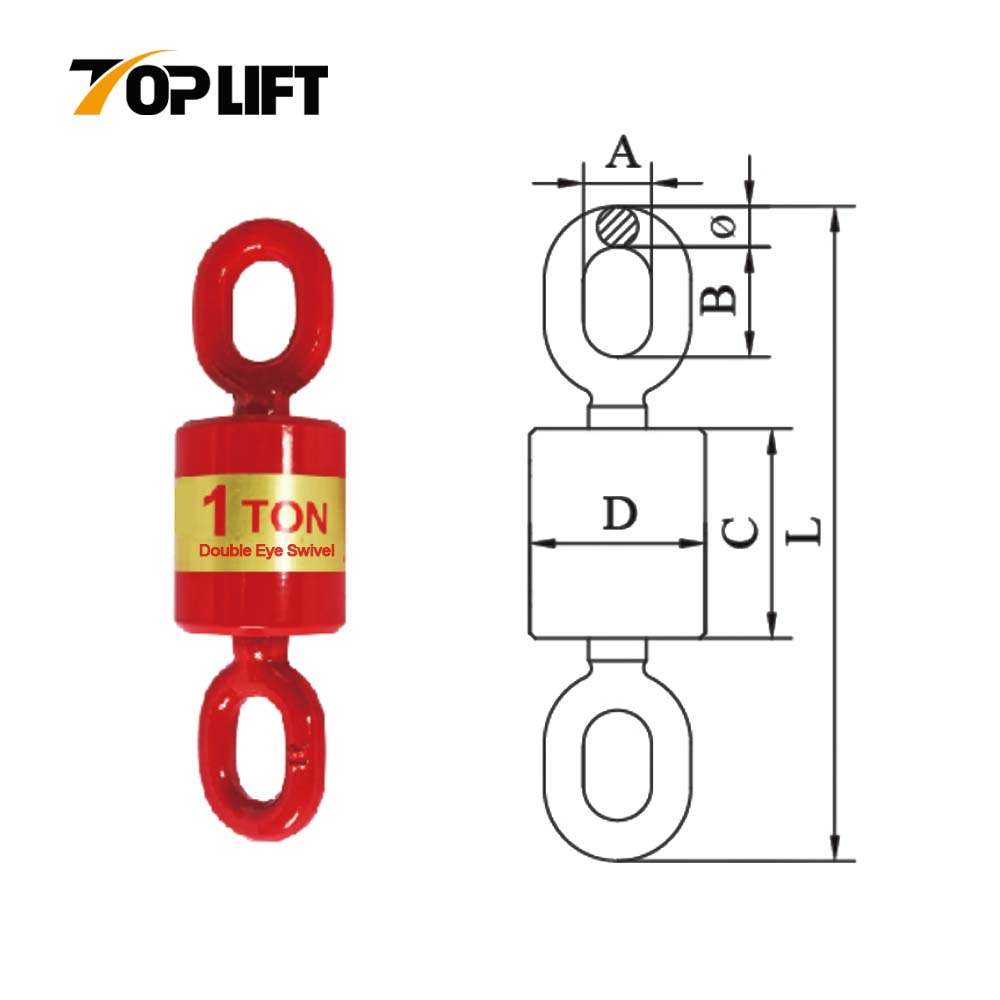

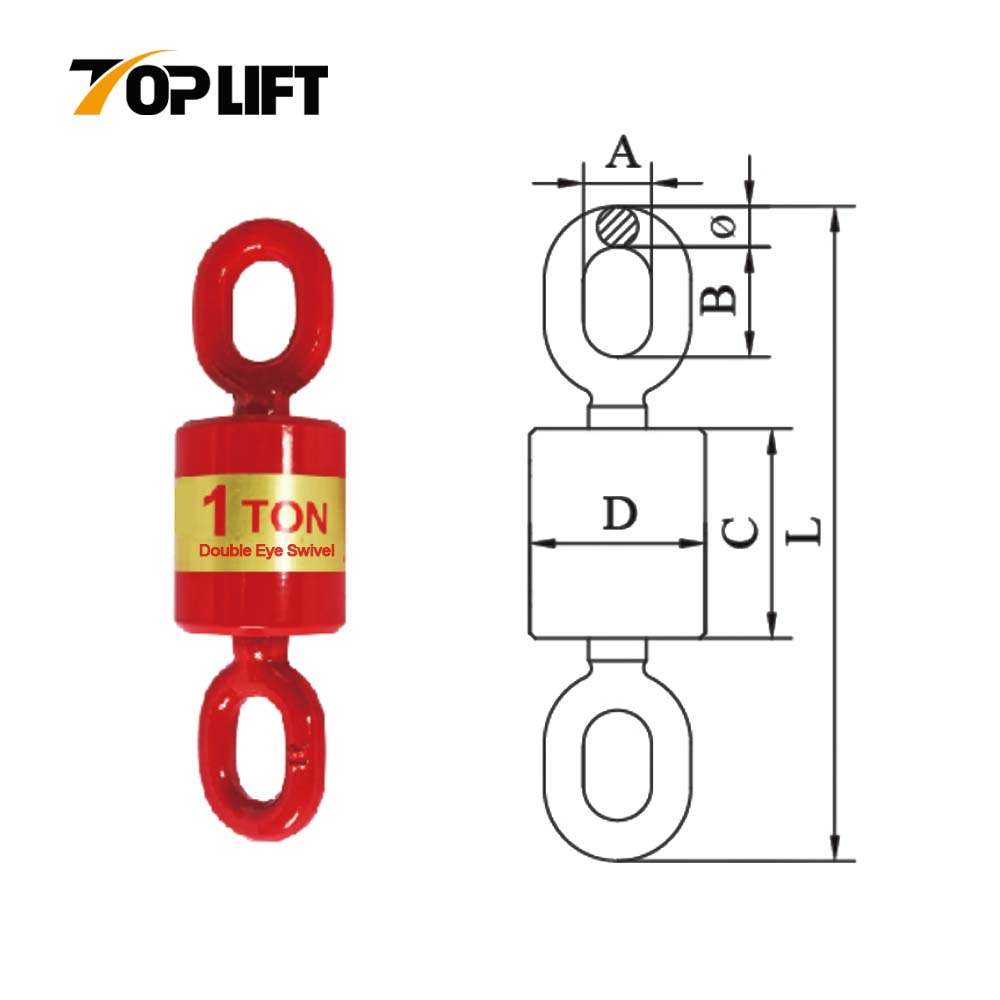

The Universal Vertical (Double Ring) lifting point is a high-strength, heavy-duty rigging accessory designed for reliable vertical lifting, turning, and rotation under load. It is widely used in machinery manufacturing, steel structures, mold moving, offshore engineering, and heavy equipment handling.

Key Features

High-strength die-forged steel:

Shackles, rings, hooks, and adapters (including oilfield rotary hooks) are produced through die forging using premium alloy steel, ensuring exceptional strength and durability.

Precision-machined main body:

The body is manufactured from round steel with precision machining for enhanced stability and load distribution.

360° rotation under full load:

Equipped with national-standard thrust bearings, allowing smooth and flexible 360-degree rotation even at rated capacity, providing safer and easier positioning during lifting.

Strict strength testing and fatigue performance:

Each unit is pull-tested at 2.5 times the rated working load.

Sample products are tested with 20,000 cyclic fatigue cycles at 1.5 times the rated load, guaranteeing long-term reliability.

100% magnaflux crack inspection:

Every unit undergoes magnetic particle crack detection to ensure internal and external integrity.

Minimum breaking strength ≥ 4 × rated load:

Offering an extra safety margin for demanding lifting jobs.

Advantages

Higher safety factor and longer service life

Full-rotation design for flexible lifting and precise positioning

Suitable for vertical lifting, load-turning, and complex rigging applications

Specification

| UNIVERSAL VERTICAL(DOUBLE RING) | ||||||||

| ITEM NO. | WLL /T | MAJOR DIMENSIONS/MM | WEIGHT /KG | |||||

| A | B | C | D | φ | L | |||

| TP-033-1 | 1 | 26 | 42 | 80 | 67 | 15.5 | 250 | 2.70 |

| TP-033-2 | 2 | 37 | 56 | 100 | 77 | 19 | 320 | 4.80 |

| TP-033-3 | 3 | 38 | 69 | 110 | 87 | 25 | 400 | 7.32 |

| TP-033-5 | 5 | 50 | 88 | 120 | 107 | 31 | 487 | 12.70 |

| TP-033-8 | 8 | 65 | 112 | 200 | 128 | 34 | 630 | 27.10 |

| TP-033-10 | 10 | 71 | 117 | 203 | 147 | 42 | 730 | 40.10 |

| Warning: Never Exceed the WLL. | ||||||||

Details

1. Shackles, rings, hooks, and adapters (oilfield rotary hooks) used die forging for high strength and quality steel

2. The main body is formed by finishing round steel.

3. The national standard pressure bearing ensures 360 - degree flexiblerotation under full loadConstruction: high strength super alloy steel die forging.

4. The manufacturing test pulling force is 2.5 times of therated load. At 1.5 times of the rated load.20.000 cyclicfatigue tests were carried out by sampling.

5. 100% magnaflux crack detection.

6. Breaking tensile force is 4 times of the rated load

Our Products

FAQ

Q: Why choose us?

A: Professional technical guidance

B: Years of production experience

C: Support for customization and design

D: Fast delivery time!

F: Special technology on print.

Q: Can the product be customized?

Yes, products can be customized according to customer requirements.

Q: Can I have samples for testing?

Yes, samples are available before bulk order.

Q: How long can I get the products?

A: For the existing sample order, 3-7 working days after payment.

B: For the customized sample order, 7-15 working days after the payment.

C: For bulk, it depends on your order quantity.

The Universal Vertical (Double Ring) lifting point is a high-strength, heavy-duty rigging accessory designed for reliable vertical lifting, turning, and rotation under load. It is widely used in machinery manufacturing, steel structures, mold moving, offshore engineering, and heavy equipment handling.

Key Features

High-strength die-forged steel:

Shackles, rings, hooks, and adapters (including oilfield rotary hooks) are produced through die forging using premium alloy steel, ensuring exceptional strength and durability.

Precision-machined main body:

The body is manufactured from round steel with precision machining for enhanced stability and load distribution.

360° rotation under full load:

Equipped with national-standard thrust bearings, allowing smooth and flexible 360-degree rotation even at rated capacity, providing safer and easier positioning during lifting.

Strict strength testing and fatigue performance:

Each unit is pull-tested at 2.5 times the rated working load.

Sample products are tested with 20,000 cyclic fatigue cycles at 1.5 times the rated load, guaranteeing long-term reliability.

100% magnaflux crack inspection:

Every unit undergoes magnetic particle crack detection to ensure internal and external integrity.

Minimum breaking strength ≥ 4 × rated load:

Offering an extra safety margin for demanding lifting jobs.

Advantages

Higher safety factor and longer service life

Full-rotation design for flexible lifting and precise positioning

Suitable for vertical lifting, load-turning, and complex rigging applications

Specification

| UNIVERSAL VERTICAL(DOUBLE RING) | ||||||||

| ITEM NO. | WLL /T | MAJOR DIMENSIONS/MM | WEIGHT /KG | |||||

| A | B | C | D | φ | L | |||

| TP-033-1 | 1 | 26 | 42 | 80 | 67 | 15.5 | 250 | 2.70 |

| TP-033-2 | 2 | 37 | 56 | 100 | 77 | 19 | 320 | 4.80 |

| TP-033-3 | 3 | 38 | 69 | 110 | 87 | 25 | 400 | 7.32 |

| TP-033-5 | 5 | 50 | 88 | 120 | 107 | 31 | 487 | 12.70 |

| TP-033-8 | 8 | 65 | 112 | 200 | 128 | 34 | 630 | 27.10 |

| TP-033-10 | 10 | 71 | 117 | 203 | 147 | 42 | 730 | 40.10 |

| Warning: Never Exceed the WLL. | ||||||||

Details

1. Shackles, rings, hooks, and adapters (oilfield rotary hooks) used die forging for high strength and quality steel

2. The main body is formed by finishing round steel.

3. The national standard pressure bearing ensures 360 - degree flexiblerotation under full loadConstruction: high strength super alloy steel die forging.

4. The manufacturing test pulling force is 2.5 times of therated load. At 1.5 times of the rated load.20.000 cyclicfatigue tests were carried out by sampling.

5. 100% magnaflux crack detection.

6. Breaking tensile force is 4 times of the rated load

Our Products

FAQ

Q: Why choose us?

A: Professional technical guidance

B: Years of production experience

C: Support for customization and design

D: Fast delivery time!

F: Special technology on print.

Q: Can the product be customized?

Yes, products can be customized according to customer requirements.

Q: Can I have samples for testing?

Yes, samples are available before bulk order.

Q: How long can I get the products?

A: For the existing sample order, 3-7 working days after payment.

B: For the customized sample order, 7-15 working days after the payment.

C: For bulk, it depends on your order quantity.