- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2024-11-22 Origin: Site

1. Requirement and Design Specification

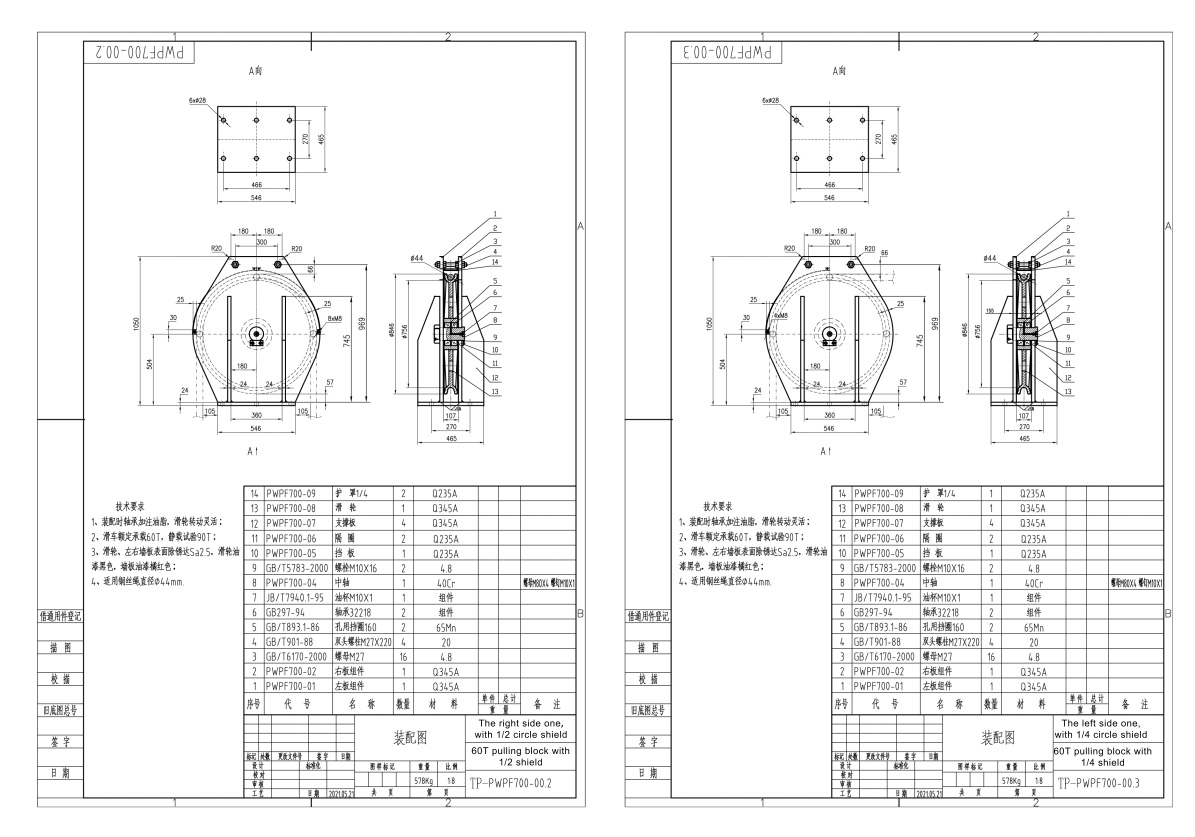

Customer Needs: OEM buyer is seeking a product - Pulley Block, explaining the desired functionality, size, compatibility, performance, and design preferences...

OEM buyer needs a Pulley block for wire rope diameter 44mm, Working Load Limit 60T, Proof Test Load 90T, With customer brand.

Quantity 200 pcs needed.

Provide Solutions for customer to choose: We work closely with OEM buys to refine design, involving modifications to our existing product and creation of a new design based on the buyer’s needs. Considering the product function and development cost, we made a plan.

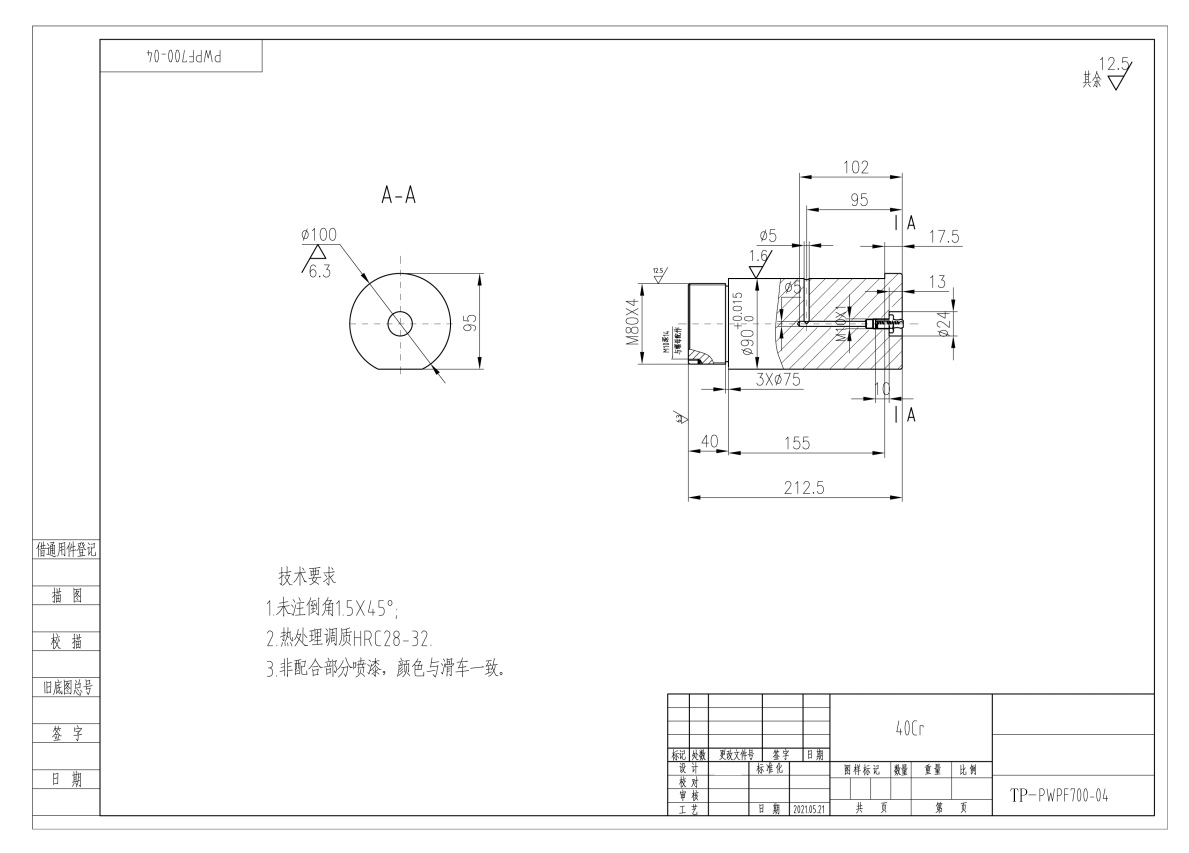

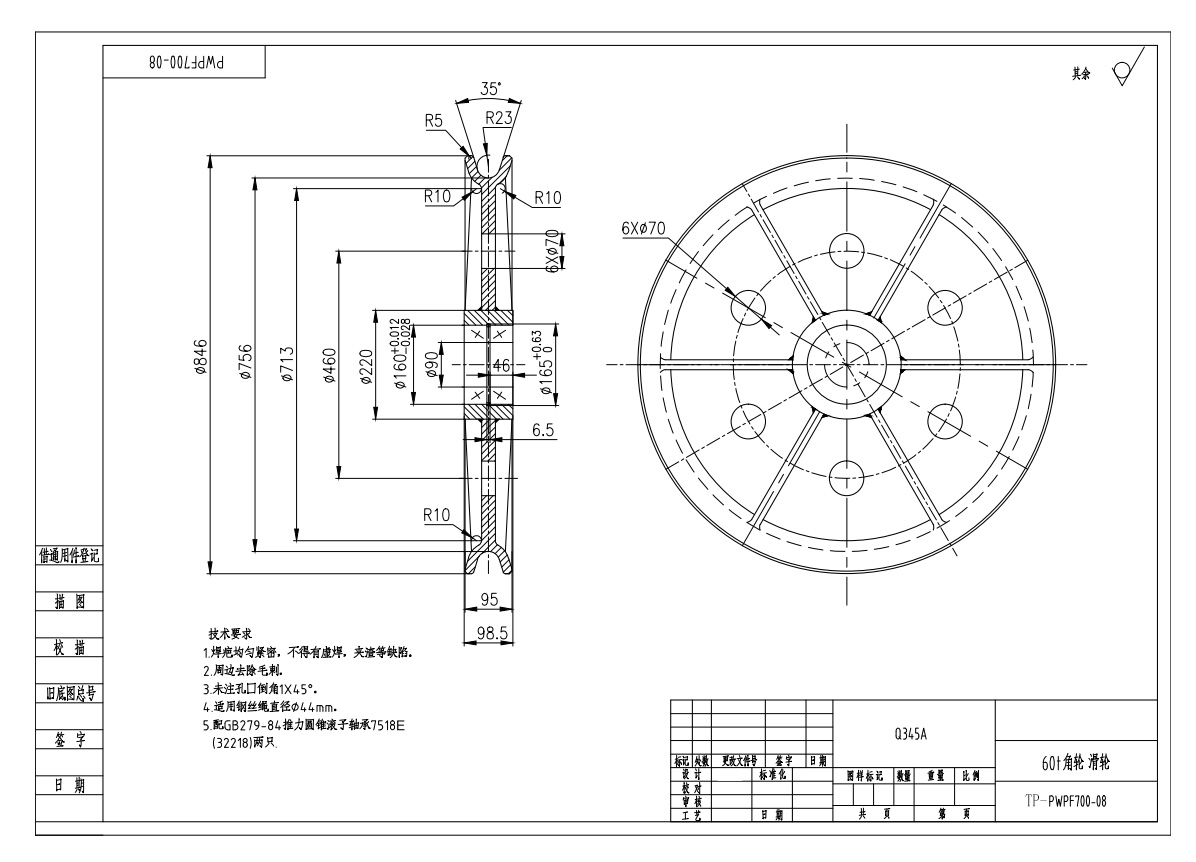

2. Drawing

Draft: We design and draft first based on the agreed-upon design and specifications.

Optimize design: Revise when ideas are changed.

3. Prototyping

Creating Mold: After repeated revisions to the drawings, We created a mold and produced a prototype based on the agreed-upon design and specifications. The prototype serves as a model to test the design, materials, and performance of the product.

Testing: The prototype is subjected to testing to ensure it meets the required standards, durability, and functionality.

Optimize design: Revise and test until Pulley Block pass the tests.

4. Mass Production

Once the prototype is approved, we set up the production line, producing large quantities of the product in accordance with the agreed schedule.

Quality Control: During this phase, we control quality control strictly to ensure that every unit produced meets the buyer’s standards and specifications.

Supply Chain Management: This involves managing the procurement of raw materials, maintaining an efficient production line, and ensuring timely delivery.

5. Customization and Branding

Branding: We design Logo for customer to confirm and print on pulley blocks.

Customization: The OEM buyer request specific adjustments, such as custom packaging, labeling, to ensure that the product fits within their brand identity.

6. Quality Assurance and Testing

100% Quality Inspection before shipping to make sure they adhere to the agreed-upon specifications and meet CE regulatory requirements.

Testing items include: Inspection for defects;Proof Load Testing

7. Packaging and Shipping

After production, the OEM product is packaged according to the buyer’s requirements.

The product is then shipped to the OEM buyer.

8. Post-Sale Support and Feedback

We offer ongoing support in terms of providing replacement parts or helping with future product revisions based on market feedback.