- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

CDH

| Availability: | |

|---|---|

| Quantity: | |

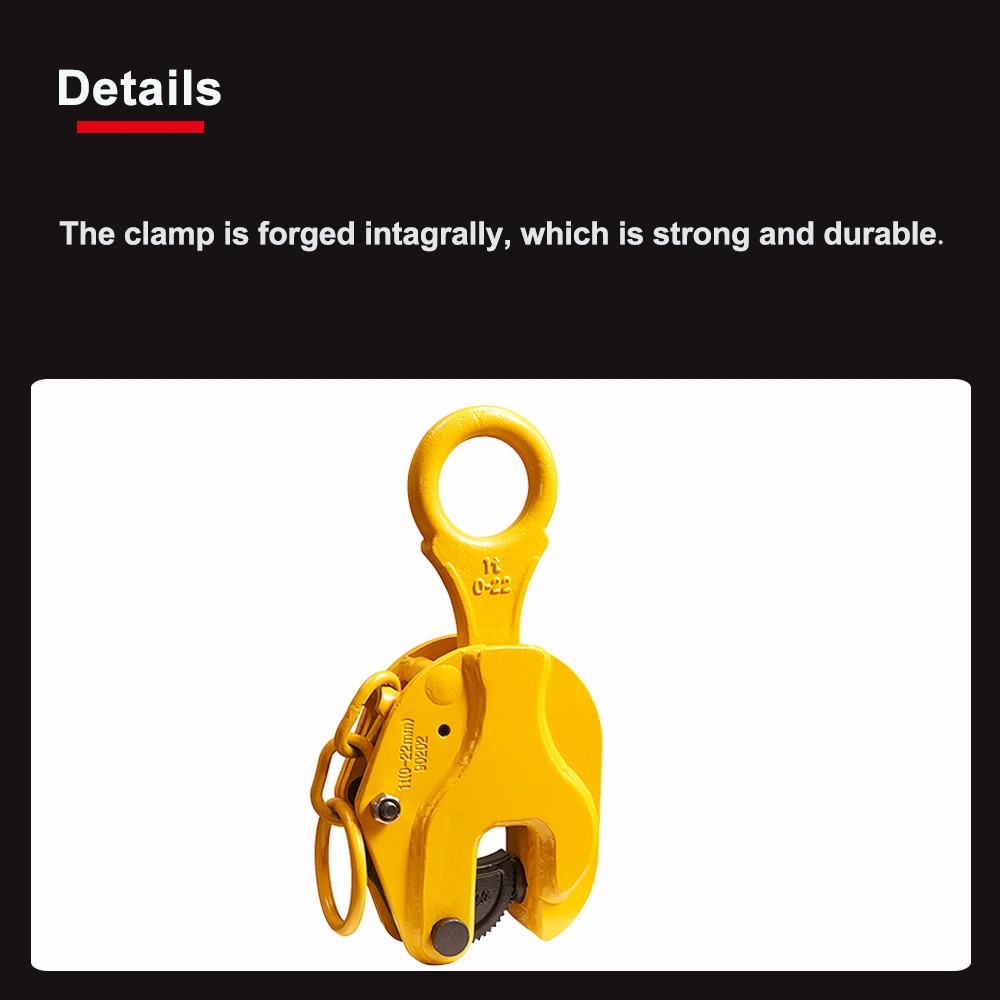

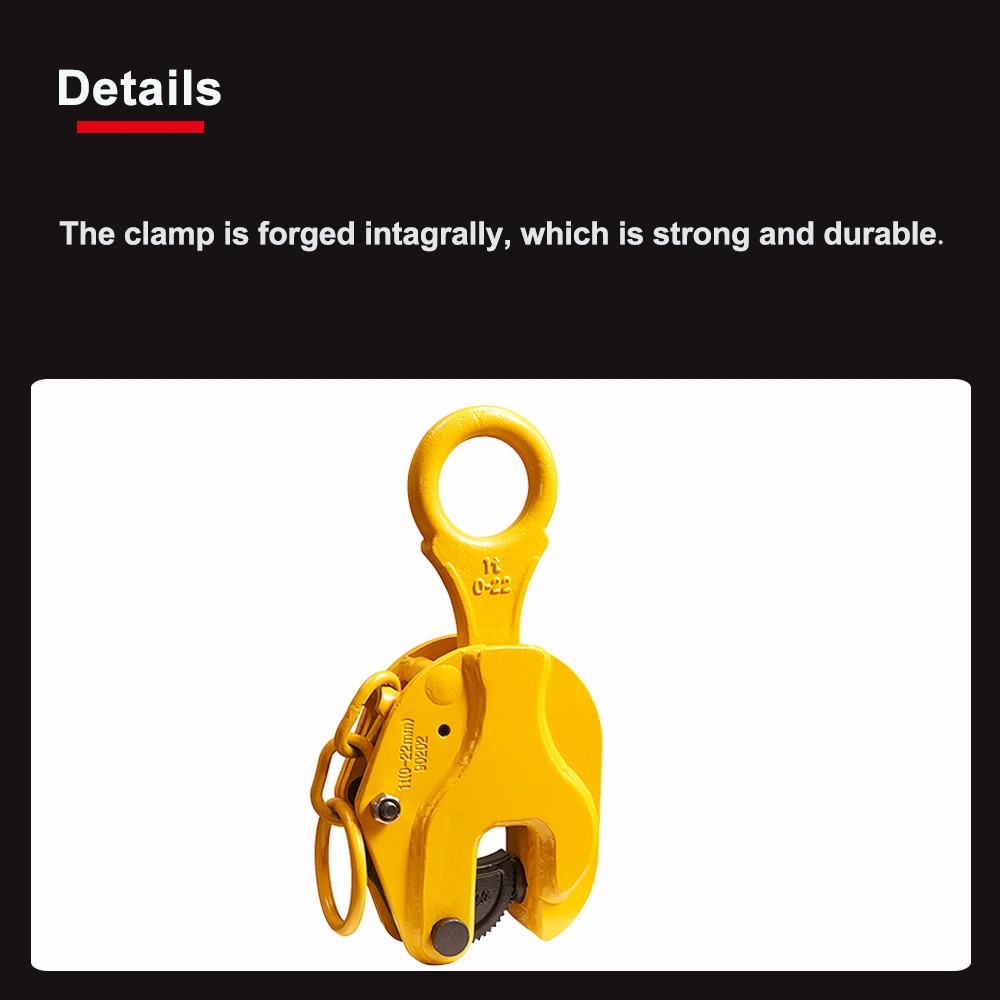

The TP-Lifting CDH Standard Plate Clamp is a high-performance lifting tool engineered for secure and efficient handling of metal plates in industrial settings. With a Working Load Limit (WLL) ranging from 800KGS to 30000KGS, it caters to both light-duty and heavy-duty plate-lifting needs, ensuring compatibility with diverse plate thicknesses and weights. Crafted from high-strength alloy steel, this clamp prioritizes durability and long-term reliability, making it a core equipment for factories, construction sites, and logistics centers that require frequent plate transportation. Its compliance with international lifting safety standards further confirms its suitability for professional industrial applications.

Integrated Safety Lock Mechanism: The built-in safety lock prevents accidental disengagement during lifting, eliminating the risk of load drops and enhancing on-site safety—critical for protecting workers and expensive equipment.

Lever-Open/Lever-Closed Operation: This user-friendly feature simplifies attaching and removing the clamp, reducing operator effort and saving time during repeated lifting cycles.

Wide Throat Opening: The large throat design offers a broader grip range, allowing the clamp to secure plates of varying thicknesses without frequent adjustments, improving operational flexibility.

Swivel Pad Design: The rotating swivel pad enables quicker release of the clamp after lifting, minimizing downtime and boosting overall work efficiency.

High-Strength Alloy Steel Construction: Resists wear, corrosion, and deformation even under heavy loads, ensuring a long service life and reducing maintenance costs.

Large Shackle Opening: Accommodates various types of lifting shackles and hooks, enhancing compatibility with existing lifting systems and avoiding the need for additional adapters.

Specification Category | Details |

Product Model | TP-Lifting CDH Standard Plate Clamp |

Working Load Limit (WLL) | 800KGS - 30000KGS |

Material | High-strength alloy steel |

Operation Type | Lever-open/lever-closed |

Lift Angle Requirement | Minimum 60° (to ensure stable load distribution) |

Grip Range | Adaptable to plate thicknesses of 6mm - 150mm (varies by WLL variant) |

Safety Compliance | Meets EN 13155 and ISO 3228 lifting equipment standards |

Shackle Opening Diameter | 25mm - 80mm (matches WLL and shackle size) |

Place of Origin | China |

Name | Vertical plate lifting clamp(CDH type) |

Material | Alloy Steel |

Surface | Painted |

Color | Yellow |

Type | Vertical |

Usage | lifting goods |

Application | Industry |

Package | Carton+Pallet |

Model | Jaw Opening (mm) | Load Capacity (kg) | T (mm) | U (mm) | V (mm) | L (mm) | Net Weight (kg) |

CDH-0.8T | 0-16 | 800 | 123 | 265 | 40 | 44 | 2.8 |

CDH-1T | 0-22 | 1000 | 124 | 295 | 50 | 54 | 3.6 |

CDH-2T | 0-30 | 2000 | 154 | 385 | 54 | 56 | 5.5 |

CDH-3T | 0-40 | 3000 | 180 | 400 | 60 | 72 | 10 |

CDH-5T | 0-50 | 5000 | 222 | 483 | 68 | 76 | 17 |

CDH-8T | 0-60 | 8000 | 265 | 535 | 65 | 90 | 26 |

CDH-10T | 0-90 | 10000 | 290 | 600 | 80 | 95 | 32 |

CDH-12T | 25-90 | 12000 | 408 | 700 | 80 | 113 | 48 |

CDH-16T | 60-125 | 16000 | 465 | 780 | 100 | 121 | 80 |

CDH-20T | 0-90 | 20000 | 563 | 933 | 100 | 140 | 149 |

CDH-30T | 10-90 | 30000 | 568 | 918 | 100 | 142 | 155 |

Steel Mill Operations: Lifting and transferring raw steel plates, hot-rolled plates, and cold-rolled plates during production and storage.

Construction Sites: Handling steel plates for building foundations, bridge structures, and high-rise steel frameworks.

Logistics & Warehousing: Loading/unloading metal plates onto trucks, ships, or storage racks in ports and warehouses.

Manufacturing Facilities: Moving heavy metal plates for machinery manufacturing, automotive part production, and equipment assembly.

Wire Ropes & Slings: Works with high-tensile steel wire ropes and synthetic slings for vertical, vertical/turn, and horizontal lifting.

Spreader Bars: Compatible with spreader bar assemblies (note: total load of the assembly must not exceed the combined WLL of two clamps).

Crane Systems: Suitable for overhead cranes, gantry cranes, and jib cranes commonly used in industrial lifting.

Each CDH Standard Plate Clamp is packaged in a heavy-duty carton with foam padding to prevent scratches and damage during transportation. For bulk orders, clamps are placed in wooden pallets secured with steel straps, ensuring stability during long-distance shipping.

Production adheres to strict quality control protocols, from raw material inspection (alloy steel certification) to final performance testing (load-bearing and safety lock function checks). The production lead time is 7-15 working days for standard WLL variants, with customizable options available for special requirements (e.g., anti-corrosion coating).

Pre-Sale Consultation: Professional team provides guidance on selecting the right WLL variant based on user’s plate weight and thickness.

After-Sale Support: Offers 12-month warranty (covers manufacturing defects) and on-site maintenance training for operators.

Replacement Parts: Supplies genuine replacement parts (e.g., swivel pads, safety lock components) with fast delivery.

The TP-Lifting CDH Standard Plate Clamp is a high-performance lifting tool engineered for secure and efficient handling of metal plates in industrial settings. With a Working Load Limit (WLL) ranging from 800KGS to 30000KGS, it caters to both light-duty and heavy-duty plate-lifting needs, ensuring compatibility with diverse plate thicknesses and weights. Crafted from high-strength alloy steel, this clamp prioritizes durability and long-term reliability, making it a core equipment for factories, construction sites, and logistics centers that require frequent plate transportation. Its compliance with international lifting safety standards further confirms its suitability for professional industrial applications.

Integrated Safety Lock Mechanism: The built-in safety lock prevents accidental disengagement during lifting, eliminating the risk of load drops and enhancing on-site safety—critical for protecting workers and expensive equipment.

Lever-Open/Lever-Closed Operation: This user-friendly feature simplifies attaching and removing the clamp, reducing operator effort and saving time during repeated lifting cycles.

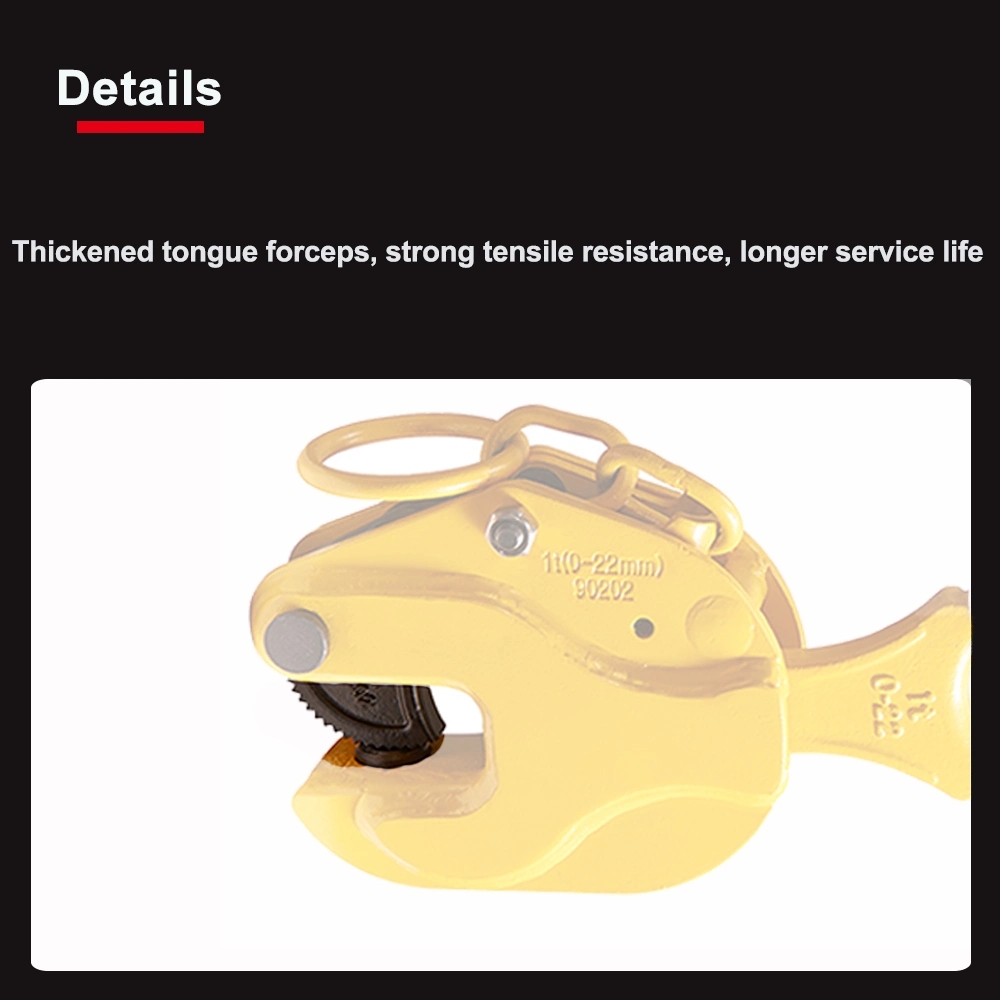

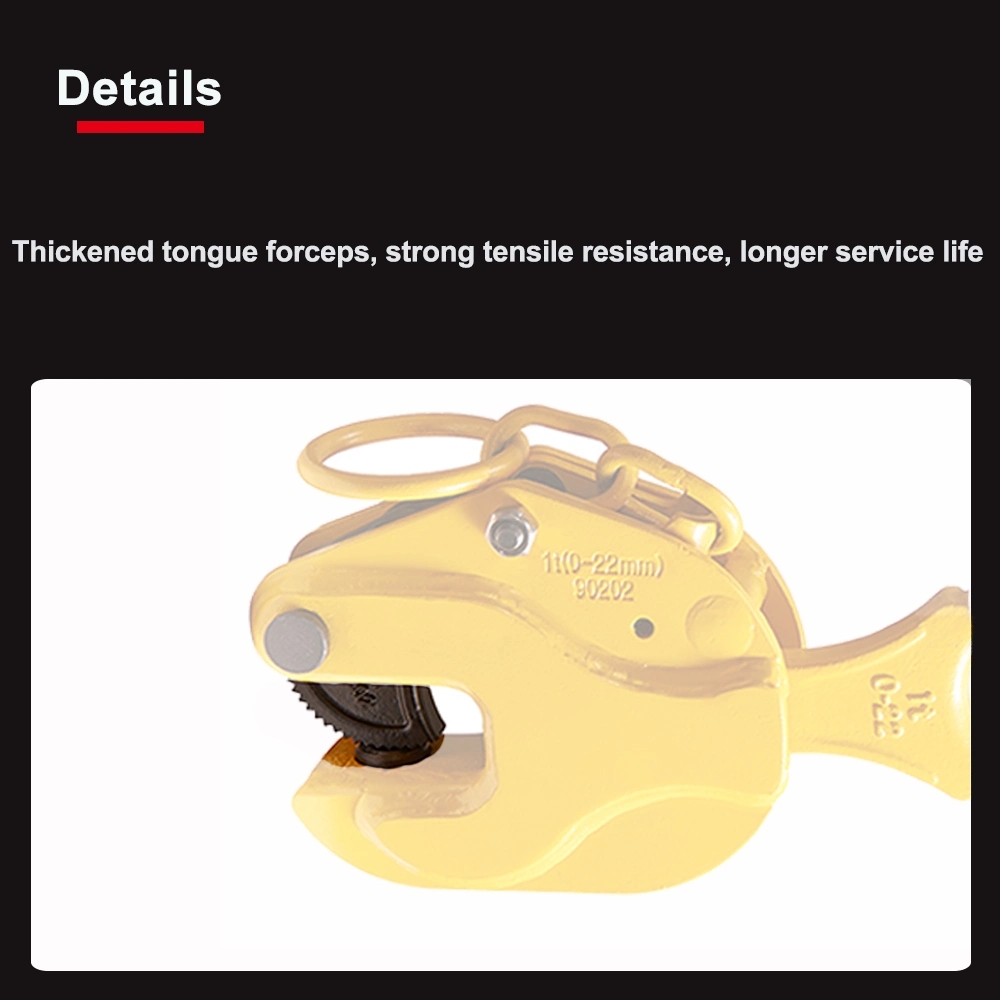

Wide Throat Opening: The large throat design offers a broader grip range, allowing the clamp to secure plates of varying thicknesses without frequent adjustments, improving operational flexibility.

Swivel Pad Design: The rotating swivel pad enables quicker release of the clamp after lifting, minimizing downtime and boosting overall work efficiency.

High-Strength Alloy Steel Construction: Resists wear, corrosion, and deformation even under heavy loads, ensuring a long service life and reducing maintenance costs.

Large Shackle Opening: Accommodates various types of lifting shackles and hooks, enhancing compatibility with existing lifting systems and avoiding the need for additional adapters.

Specification Category | Details |

Product Model | TP-Lifting CDH Standard Plate Clamp |

Working Load Limit (WLL) | 800KGS - 30000KGS |

Material | High-strength alloy steel |

Operation Type | Lever-open/lever-closed |

Lift Angle Requirement | Minimum 60° (to ensure stable load distribution) |

Grip Range | Adaptable to plate thicknesses of 6mm - 150mm (varies by WLL variant) |

Safety Compliance | Meets EN 13155 and ISO 3228 lifting equipment standards |

Shackle Opening Diameter | 25mm - 80mm (matches WLL and shackle size) |

Place of Origin | China |

Name | Vertical plate lifting clamp(CDH type) |

Material | Alloy Steel |

Surface | Painted |

Color | Yellow |

Type | Vertical |

Usage | lifting goods |

Application | Industry |

Package | Carton+Pallet |

Model | Jaw Opening (mm) | Load Capacity (kg) | T (mm) | U (mm) | V (mm) | L (mm) | Net Weight (kg) |

CDH-0.8T | 0-16 | 800 | 123 | 265 | 40 | 44 | 2.8 |

CDH-1T | 0-22 | 1000 | 124 | 295 | 50 | 54 | 3.6 |

CDH-2T | 0-30 | 2000 | 154 | 385 | 54 | 56 | 5.5 |

CDH-3T | 0-40 | 3000 | 180 | 400 | 60 | 72 | 10 |

CDH-5T | 0-50 | 5000 | 222 | 483 | 68 | 76 | 17 |

CDH-8T | 0-60 | 8000 | 265 | 535 | 65 | 90 | 26 |

CDH-10T | 0-90 | 10000 | 290 | 600 | 80 | 95 | 32 |

CDH-12T | 25-90 | 12000 | 408 | 700 | 80 | 113 | 48 |

CDH-16T | 60-125 | 16000 | 465 | 780 | 100 | 121 | 80 |

CDH-20T | 0-90 | 20000 | 563 | 933 | 100 | 140 | 149 |

CDH-30T | 10-90 | 30000 | 568 | 918 | 100 | 142 | 155 |

Steel Mill Operations: Lifting and transferring raw steel plates, hot-rolled plates, and cold-rolled plates during production and storage.

Construction Sites: Handling steel plates for building foundations, bridge structures, and high-rise steel frameworks.

Logistics & Warehousing: Loading/unloading metal plates onto trucks, ships, or storage racks in ports and warehouses.

Manufacturing Facilities: Moving heavy metal plates for machinery manufacturing, automotive part production, and equipment assembly.

Wire Ropes & Slings: Works with high-tensile steel wire ropes and synthetic slings for vertical, vertical/turn, and horizontal lifting.

Spreader Bars: Compatible with spreader bar assemblies (note: total load of the assembly must not exceed the combined WLL of two clamps).

Crane Systems: Suitable for overhead cranes, gantry cranes, and jib cranes commonly used in industrial lifting.

Each CDH Standard Plate Clamp is packaged in a heavy-duty carton with foam padding to prevent scratches and damage during transportation. For bulk orders, clamps are placed in wooden pallets secured with steel straps, ensuring stability during long-distance shipping.

Production adheres to strict quality control protocols, from raw material inspection (alloy steel certification) to final performance testing (load-bearing and safety lock function checks). The production lead time is 7-15 working days for standard WLL variants, with customizable options available for special requirements (e.g., anti-corrosion coating).

Pre-Sale Consultation: Professional team provides guidance on selecting the right WLL variant based on user’s plate weight and thickness.

After-Sale Support: Offers 12-month warranty (covers manufacturing defects) and on-site maintenance training for operators.

Replacement Parts: Supplies genuine replacement parts (e.g., swivel pads, safety lock components) with fast delivery.