- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

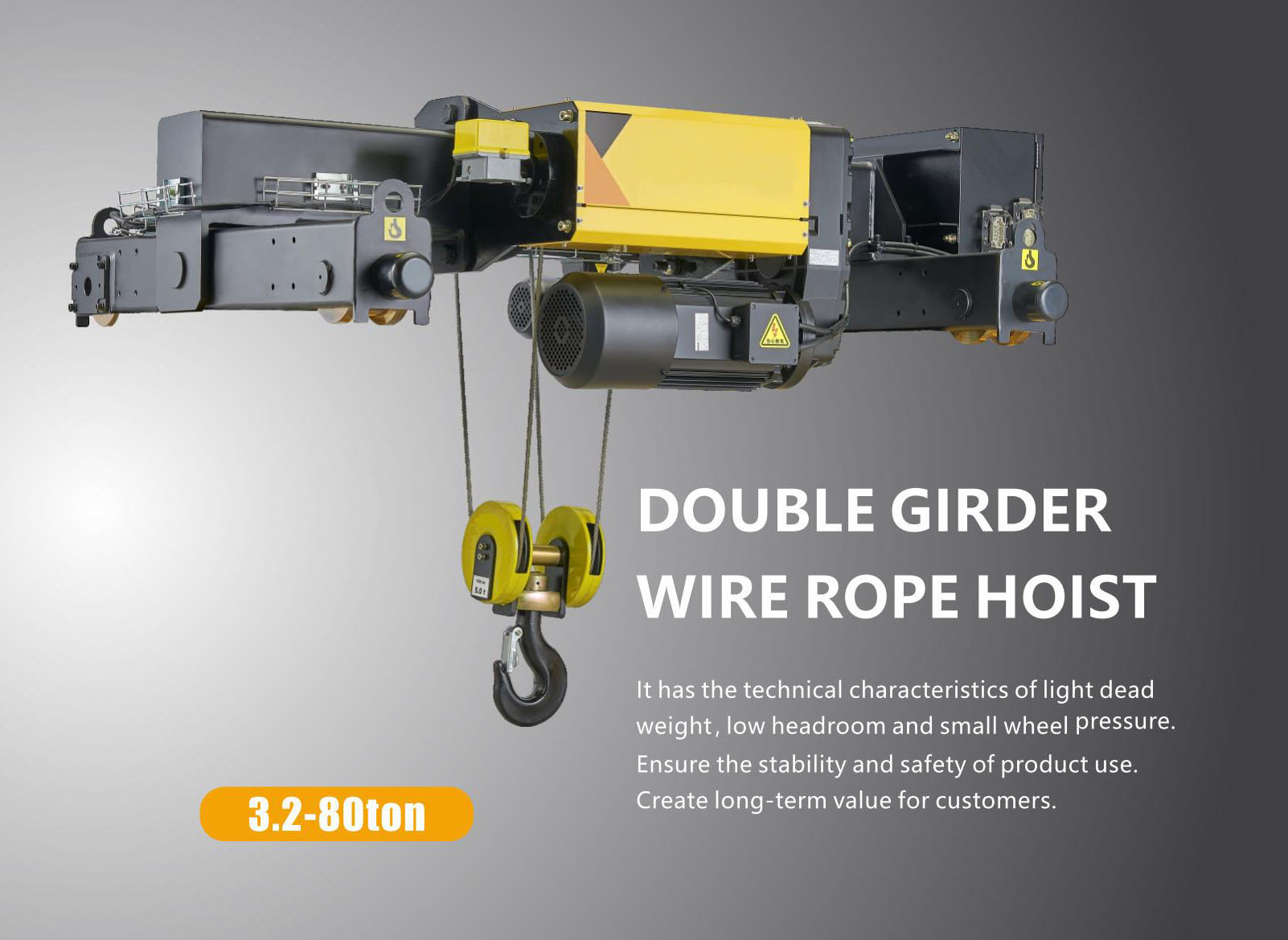

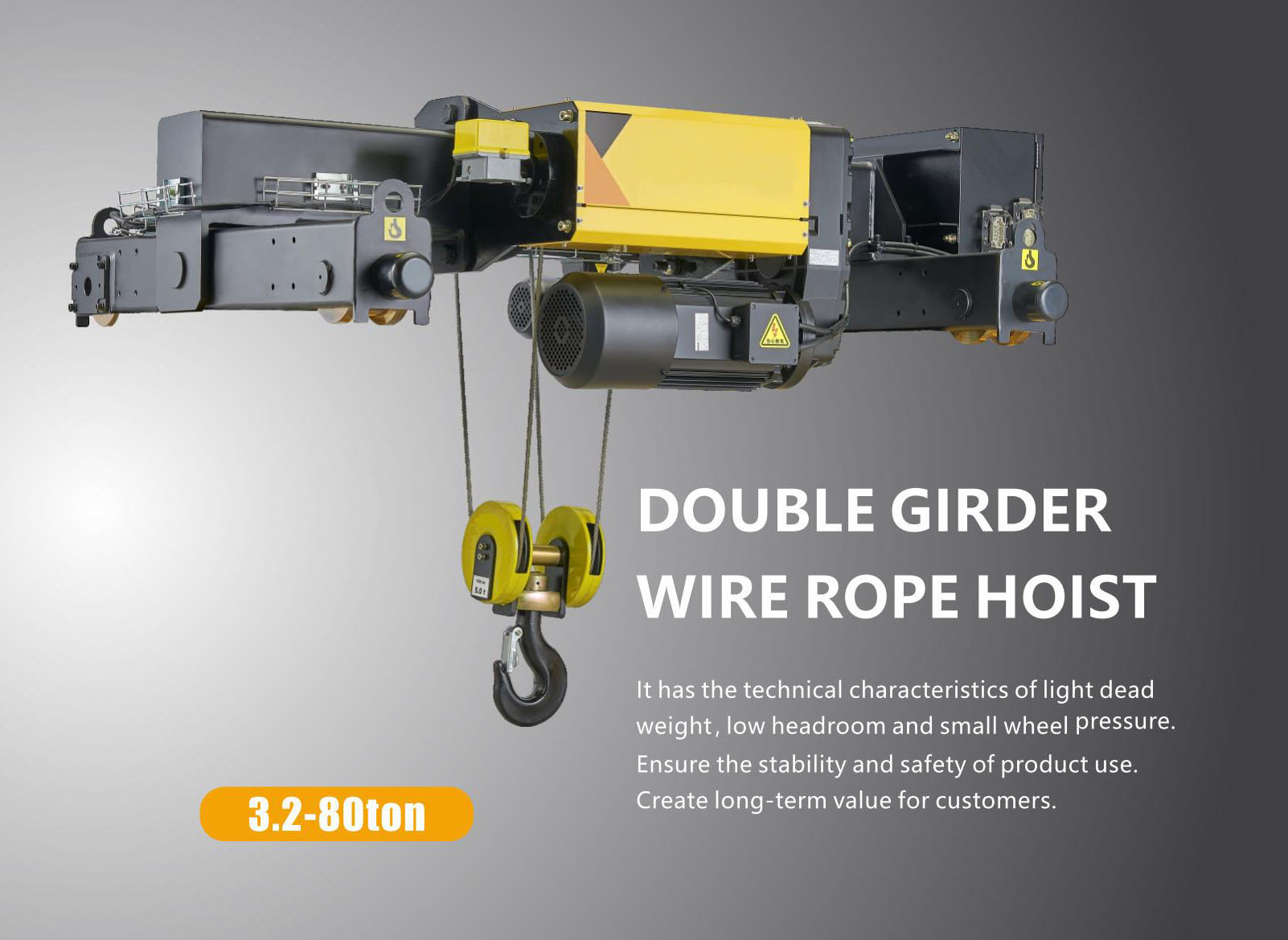

Double Grider Electric Wire Rope Hoist

| Availability: | |

|---|---|

| Quantity: | |

Double Grider Electric Wire Rope Hoist is integrated with a frequency conversion motor trolley, enabling smooth and efficient lifting operations with a capacity ranging from 16T to 80T and a lifting height of 6m to 18m. Equipped with core components like electromagnetic disc brake and overload limiter, it ensures stable and safe material handling, perfectly meeting the strict requirements of FEM/ISO work levels (M4-M5). As a leading electric lifting equipment manufacturer, we deliver products that balance power and precision, making it an ideal choice for large-scale lifting tasks.

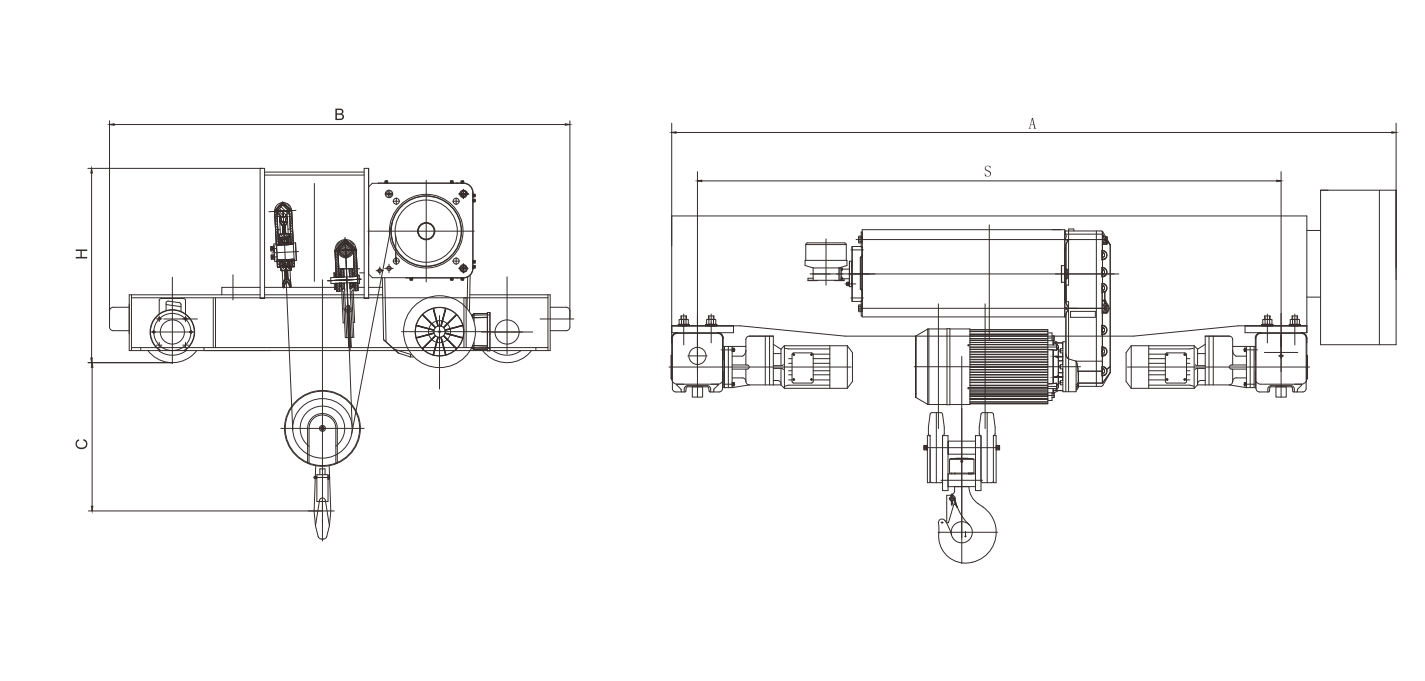

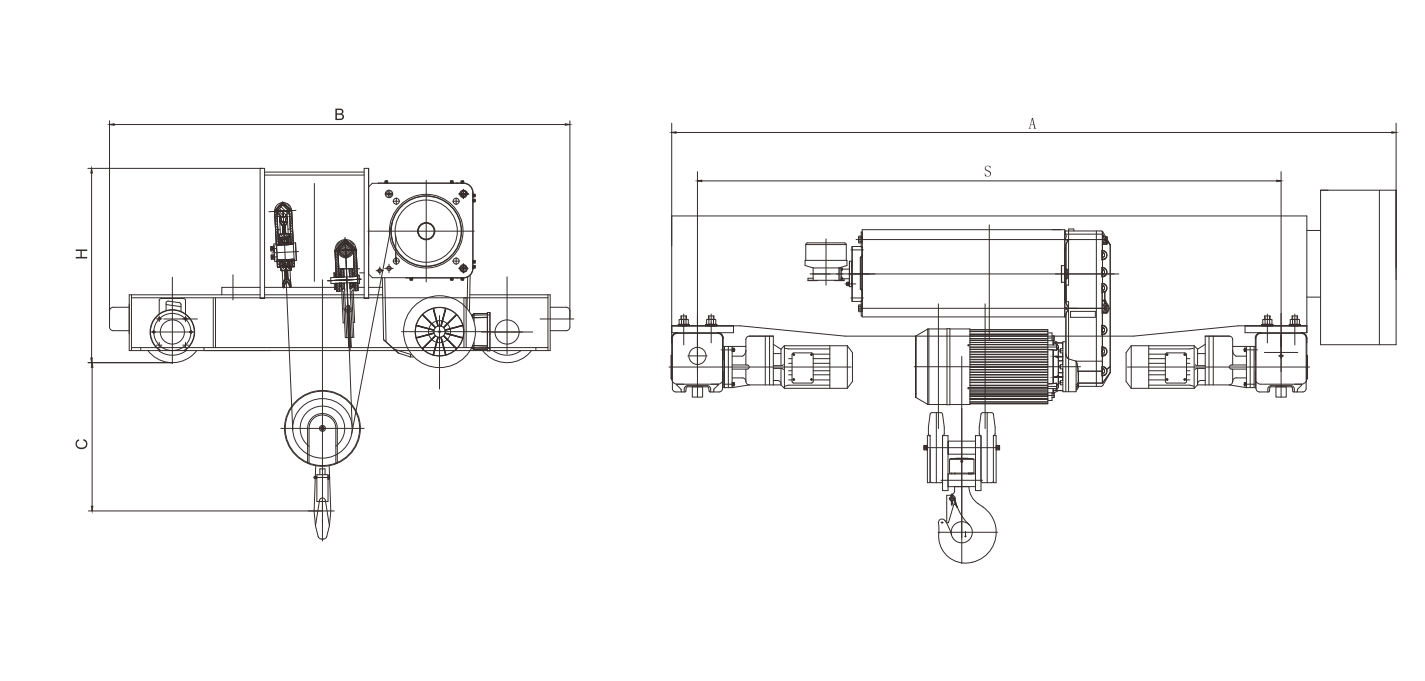

Type | Capacity | Lifting | Work | Lifting | Lifting | Travelling | Travelling | Size H | Size C | Size A | Size B | Size S |

TP-16.0 | 16.0 | 6 | 2m/M5 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 2150 | 1610 | 1700 |

TP-16.0 | 16.0 | 9 | 2m/M5 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 2450 | 1610 | 2000 |

TP-16.0 | 16.0 | 12 | 2m/M5 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 2850 | 1610 | 2400 |

TP-16.0 | 16.0 | 15 | 2m/M5 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 3150 | 1610 | 2700 |

TP-16.0 | 16.0 | 18 | 2m/M5 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 3550 | 1610 | 3100 |

TP-20.0 | 20.0 | 6 | 1AM/M4 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 2150 | 1610 | 1700 |

TP-20.0 | 20.0 | 9 | 1AM/M4 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 2450 | 1610 | 2000 |

TP-20.0 | 20.0 | 12 | 1AM/M4 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 2850 | 1610 | 2400 |

TP-20.0 | 20.0 | 15 | 1AM/M4 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 3150 | 1610 | 2700 |

TP-20.0 | 20.0 | 18 | 1AM/M4 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 3550 | 1610 | 3100 |

TP-25.0 | 25.0 | 6 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 2450 | 1850 | 2000 |

TP-25.0 | 25.0 | 9 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 2850 | 1850 | 2400 |

TP-25.0 | 25.0 | 12 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 3550 | 1850 | 3100 |

TP-25.0 | 25.0 | 15 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 3550 | 1850 | 3100 |

TP-25.0 | 25.0 | 18 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 3850 | 1850 | 3400 |

TP-32.0 | 32.0 | 6 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 2450 | 1850 | 2000 |

TP-32.0 | 32.0 | 9 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 2850 | 1850 | 2400 |

TP-32.0 | 32.0 | 12 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 3550 | 1850 | 3100 |

TP-32.0 | 32.0 | 15 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 3550 | 1850 | 3100 |

TP-32.0 | 32.0 | 18 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 3850 | 1850 | 3400 |

TP-40.0 | 40.0 | 6 | 1AM/M4 | 0-4.9 | 38 | 5-20 | 1.5*2 | 895 | 980 | 2650 | 2140 | 2000 |

TP-40.0 | 40.0 | 9 | 1AM/M4 | 0-4.9 | 38 | 5-20 | 1.5*2 | 895 | 980 | 2650 | 2140 | 2000 |

TP-40.0 | 40.0 | 12 | 1AM/M4 | 0-4.9 | 38 | 5-20 | 1.5*2 | 895 | 980 | 3050 | 2140 | 2400 |

TP-40.0 | 40.0 | 15 | 1AM/M4 | 0-4.9 | 38 | 5-20 | 1.5*2 | 895 | 980 | 3350 | 2140 | 2700 |

TP-40.0 | 40.0 | 18 | 1AM/M4 | 0-4.9 | 38 | 5-20 | 1.5*2 | 895 | 980 | 3750 | 2140 | 3100 |

TP-50.0 | 50.0 | 6 | 2m/M5 | 0-3.2 | 38 | 5-20 | 1.5*2 | 895 | 980 | 2650 | 2100 | 2000 |

TP-50.0 | 50.0 | 9 | 2m/M5 | 0-3.2 | 38 | 5-20 | 1.5*2 | 895 | 980 | 3050 | 2100 | 2400 |

TP-50.0 | 50.0 | 12 | 2m/M5 | 0-3.2 | 38 | 5-20 | 1.5*2 | 895 | 980 | 3750 | 2100 | 3100 |

TP-50.0 | 50.0 | 15 | 2m/M5 | 0-3.2 | 38 | 5-20 | 1.5*2 | 895 | 980 | 4450 | 2100 | 3800 |

TP-50.0 | 50.0 | 18 | 2m/M5 | 0-3.2 | 38 | 5-20 | 1.5*2 | 895 | 980 | 4850 | 2100 | 4200 |

TP-63.0 | 63.0 | 6 | 1AM/M4 | 0-3.2 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 2700 | 2220 | 2000 |

TP-63.0 | 63.0 | 9 | 1AM/M4 | 0-3.2 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 3100 | 2220 | 2400 |

TP-63.0 | 63.0 | 12 | 1AM/M4 | 0-3.2 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 3800 | 2220 | 3100 |

TP-63.0 | 63.0 | 15 | 1AM/M4 | 0-3.2 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 4500 | 2220 | 3800 |

TP-63.0 | 63.0 | 18 | 1AM/M4 | 0-3.2 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 4900 | 2220 | 4200 |

TP-80.0 | 80.0 | 6 | 1AM/M4 | 0~2.4 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 3100 | 2220 | 2400 |

TP-80.0 | 80.0 | 9 | 1AM/M4 | 0~2.4 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 3800 | 2220 | 3100 |

TP-80.0 | 80.0 | 12 | 1AM/M4 | 0~2.4 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 4500 | 2220 | 3800 |

TP-80.0 | 80.0 | 15 | 1AM/M4 | 0~2.4 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 4900 | 2220 | 4200 |

TP-80.0 | 80.0 | 18 | 1AM/M4 | 0~2.4 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 5500 | 2220 | 4800 |

The Heavy Duty Double Grider Electric Wire Rope Hoist boasts a modular design, with all key parts precisely assembled to achieve a compact structure without compromising lifting capacity. Its streamlined body reduces installation space, while the robust grider structure enhances load-bearing stability.

Key visible components include the safety latch hook that prevents accidental load slipping, the durable wire rope system for reliable lifting, and the user-friendly control panel with low-voltage control (24V/36V/48V/110V) for secure operation. The hoist’s surface is treated to resist corrosion, adapting to harsh working environments from -20°C to +40°C.

With a dual-speed lifting system (e.g., 4/0.6 m/min for 16T model) and adjustable travelling speed (5-20 m/min), the hoist achieves precise positioning of heavy loads, minimizing operation time and improving work efficiency.

The frequency conversion motor reduces energy consumption significantly while lowering operational noise, creating a more eco-friendly and comfortable working environment compared to traditional hoists.

Equipped with overload limiter and motor overheat protection, the hoist automatically stops when exceeding load limits or facing motor overheating, avoiding potential accidents. The IP54 protection grade ensures dust and water resistance, suitable for various harsh working conditions.

Our Heavy Duty Double Grider Electric Wire Rope Hoist complies with international FEM/ISO standards, with an insulation grade of F to ensure stable performance under high-temperature conditions. Every unit undergoes rigorous testing before leaving the factory, including load-bearing tests and safety function checks.

We hold CE certification for our hoist products, guaranteeing that they meet European safety and quality standards. Additionally, we provide a comprehensive after-sales service, including on-site installation guidance and maintenance support, to ensure long-term and stable operation of the equipment.

Yes, we accept OEM orders and provide confidentiality agreements to protect your design privacy. We can customize the hoist according to your brand and specific requirements.

Absolutely. Just provide us with detailed parameters such as lifting capacity, lifting height, and work level, and we will offer a professional quotation and customized solution.

We will send you real-time updates and photos at different production stages. You can also contact our sales team at any time for the latest information about your order.

Double Grider Electric Wire Rope Hoist is integrated with a frequency conversion motor trolley, enabling smooth and efficient lifting operations with a capacity ranging from 16T to 80T and a lifting height of 6m to 18m. Equipped with core components like electromagnetic disc brake and overload limiter, it ensures stable and safe material handling, perfectly meeting the strict requirements of FEM/ISO work levels (M4-M5). As a leading electric lifting equipment manufacturer, we deliver products that balance power and precision, making it an ideal choice for large-scale lifting tasks.

Type | Capacity | Lifting | Work | Lifting | Lifting | Travelling | Travelling | Size H | Size C | Size A | Size B | Size S |

TP-16.0 | 16.0 | 6 | 2m/M5 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 2150 | 1610 | 1700 |

TP-16.0 | 16.0 | 9 | 2m/M5 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 2450 | 1610 | 2000 |

TP-16.0 | 16.0 | 12 | 2m/M5 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 2850 | 1610 | 2400 |

TP-16.0 | 16.0 | 15 | 2m/M5 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 3150 | 1610 | 2700 |

TP-16.0 | 16.0 | 18 | 2m/M5 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 3550 | 1610 | 3100 |

TP-20.0 | 20.0 | 6 | 1AM/M4 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 2150 | 1610 | 1700 |

TP-20.0 | 20.0 | 9 | 1AM/M4 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 2450 | 1610 | 2000 |

TP-20.0 | 20.0 | 12 | 1AM/M4 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 2850 | 1610 | 2400 |

TP-20.0 | 20.0 | 15 | 1AM/M4 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 3150 | 1610 | 2700 |

TP-20.0 | 20.0 | 18 | 1AM/M4 | 4/0.6 | 16/2.6 | 5-20 | 0.55*2 | 640 | 480 | 3550 | 1610 | 3100 |

TP-25.0 | 25.0 | 6 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 2450 | 1850 | 2000 |

TP-25.0 | 25.0 | 9 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 2850 | 1850 | 2400 |

TP-25.0 | 25.0 | 12 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 3550 | 1850 | 3100 |

TP-25.0 | 25.0 | 15 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 3550 | 1850 | 3100 |

TP-25.0 | 25.0 | 18 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 3850 | 1850 | 3400 |

TP-32.0 | 32.0 | 6 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 2450 | 1850 | 2000 |

TP-32.0 | 32.0 | 9 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 2850 | 1850 | 2400 |

TP-32.0 | 32.0 | 12 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 3550 | 1850 | 3100 |

TP-32.0 | 32.0 | 15 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 3550 | 1850 | 3100 |

TP-32.0 | 32.0 | 18 | 2m/M5 | 3.3/0.8 | 20/5 | 5-20 | 1.1*2 | 790 | 620 | 3850 | 1850 | 3400 |

TP-40.0 | 40.0 | 6 | 1AM/M4 | 0-4.9 | 38 | 5-20 | 1.5*2 | 895 | 980 | 2650 | 2140 | 2000 |

TP-40.0 | 40.0 | 9 | 1AM/M4 | 0-4.9 | 38 | 5-20 | 1.5*2 | 895 | 980 | 2650 | 2140 | 2000 |

TP-40.0 | 40.0 | 12 | 1AM/M4 | 0-4.9 | 38 | 5-20 | 1.5*2 | 895 | 980 | 3050 | 2140 | 2400 |

TP-40.0 | 40.0 | 15 | 1AM/M4 | 0-4.9 | 38 | 5-20 | 1.5*2 | 895 | 980 | 3350 | 2140 | 2700 |

TP-40.0 | 40.0 | 18 | 1AM/M4 | 0-4.9 | 38 | 5-20 | 1.5*2 | 895 | 980 | 3750 | 2140 | 3100 |

TP-50.0 | 50.0 | 6 | 2m/M5 | 0-3.2 | 38 | 5-20 | 1.5*2 | 895 | 980 | 2650 | 2100 | 2000 |

TP-50.0 | 50.0 | 9 | 2m/M5 | 0-3.2 | 38 | 5-20 | 1.5*2 | 895 | 980 | 3050 | 2100 | 2400 |

TP-50.0 | 50.0 | 12 | 2m/M5 | 0-3.2 | 38 | 5-20 | 1.5*2 | 895 | 980 | 3750 | 2100 | 3100 |

TP-50.0 | 50.0 | 15 | 2m/M5 | 0-3.2 | 38 | 5-20 | 1.5*2 | 895 | 980 | 4450 | 2100 | 3800 |

TP-50.0 | 50.0 | 18 | 2m/M5 | 0-3.2 | 38 | 5-20 | 1.5*2 | 895 | 980 | 4850 | 2100 | 4200 |

TP-63.0 | 63.0 | 6 | 1AM/M4 | 0-3.2 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 2700 | 2220 | 2000 |

TP-63.0 | 63.0 | 9 | 1AM/M4 | 0-3.2 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 3100 | 2220 | 2400 |

TP-63.0 | 63.0 | 12 | 1AM/M4 | 0-3.2 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 3800 | 2220 | 3100 |

TP-63.0 | 63.0 | 15 | 1AM/M4 | 0-3.2 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 4500 | 2220 | 3800 |

TP-63.0 | 63.0 | 18 | 1AM/M4 | 0-3.2 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 4900 | 2220 | 4200 |

TP-80.0 | 80.0 | 6 | 1AM/M4 | 0~2.4 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 3100 | 2220 | 2400 |

TP-80.0 | 80.0 | 9 | 1AM/M4 | 0~2.4 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 3800 | 2220 | 3100 |

TP-80.0 | 80.0 | 12 | 1AM/M4 | 0~2.4 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 4500 | 2220 | 3800 |

TP-80.0 | 80.0 | 15 | 1AM/M4 | 0~2.4 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 4900 | 2220 | 4200 |

TP-80.0 | 80.0 | 18 | 1AM/M4 | 0~2.4 | 38 | 5-20 | 2.2*2 | 975 | 1110 | 5500 | 2220 | 4800 |

The Heavy Duty Double Grider Electric Wire Rope Hoist boasts a modular design, with all key parts precisely assembled to achieve a compact structure without compromising lifting capacity. Its streamlined body reduces installation space, while the robust grider structure enhances load-bearing stability.

Key visible components include the safety latch hook that prevents accidental load slipping, the durable wire rope system for reliable lifting, and the user-friendly control panel with low-voltage control (24V/36V/48V/110V) for secure operation. The hoist’s surface is treated to resist corrosion, adapting to harsh working environments from -20°C to +40°C.

With a dual-speed lifting system (e.g., 4/0.6 m/min for 16T model) and adjustable travelling speed (5-20 m/min), the hoist achieves precise positioning of heavy loads, minimizing operation time and improving work efficiency.

The frequency conversion motor reduces energy consumption significantly while lowering operational noise, creating a more eco-friendly and comfortable working environment compared to traditional hoists.

Equipped with overload limiter and motor overheat protection, the hoist automatically stops when exceeding load limits or facing motor overheating, avoiding potential accidents. The IP54 protection grade ensures dust and water resistance, suitable for various harsh working conditions.

Our Heavy Duty Double Grider Electric Wire Rope Hoist complies with international FEM/ISO standards, with an insulation grade of F to ensure stable performance under high-temperature conditions. Every unit undergoes rigorous testing before leaving the factory, including load-bearing tests and safety function checks.

We hold CE certification for our hoist products, guaranteeing that they meet European safety and quality standards. Additionally, we provide a comprehensive after-sales service, including on-site installation guidance and maintenance support, to ensure long-term and stable operation of the equipment.

Yes, we accept OEM orders and provide confidentiality agreements to protect your design privacy. We can customize the hoist according to your brand and specific requirements.

Absolutely. Just provide us with detailed parameters such as lifting capacity, lifting height, and work level, and we will offer a professional quotation and customized solution.

We will send you real-time updates and photos at different production stages. You can also contact our sales team at any time for the latest information about your order.