- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

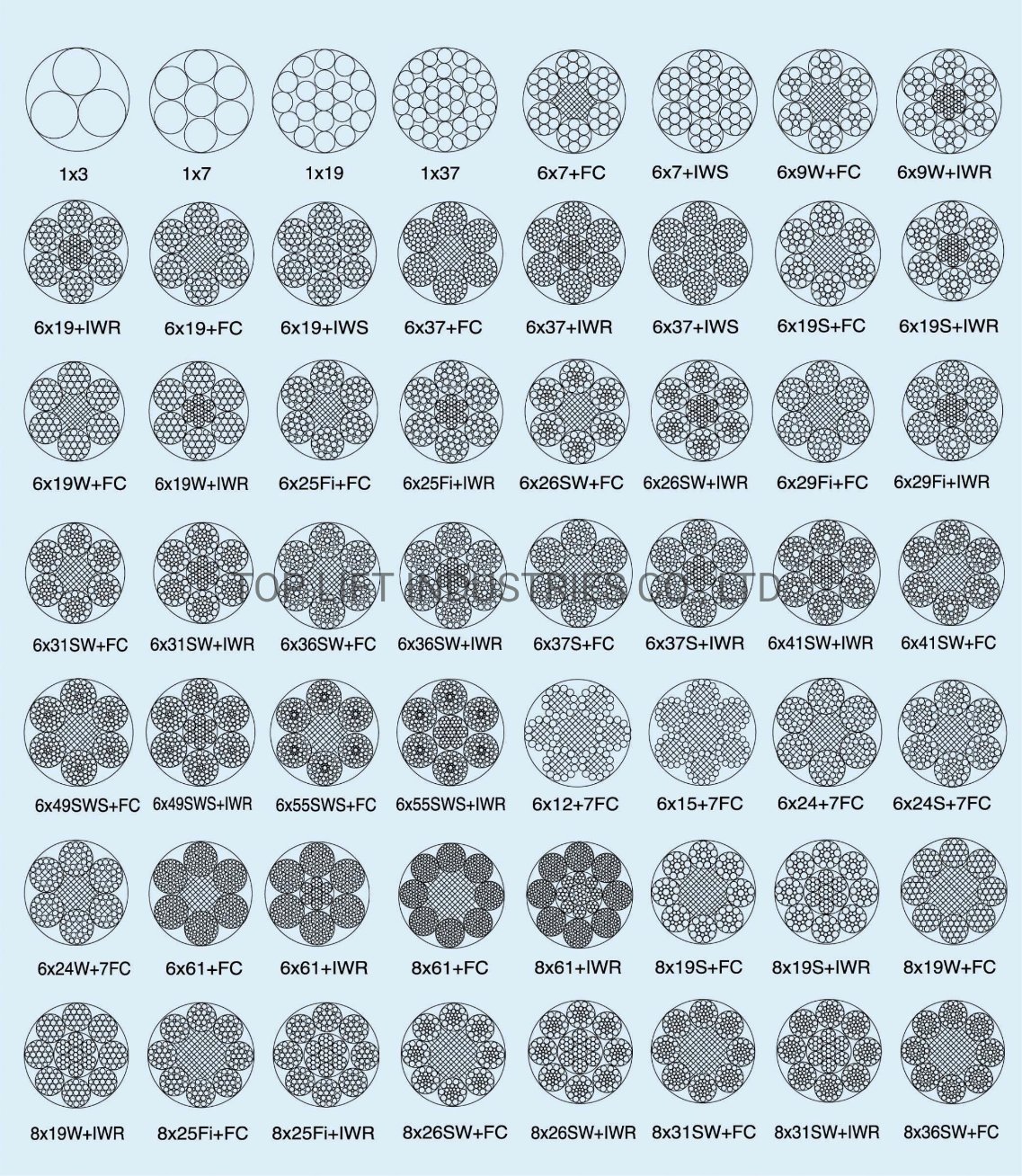

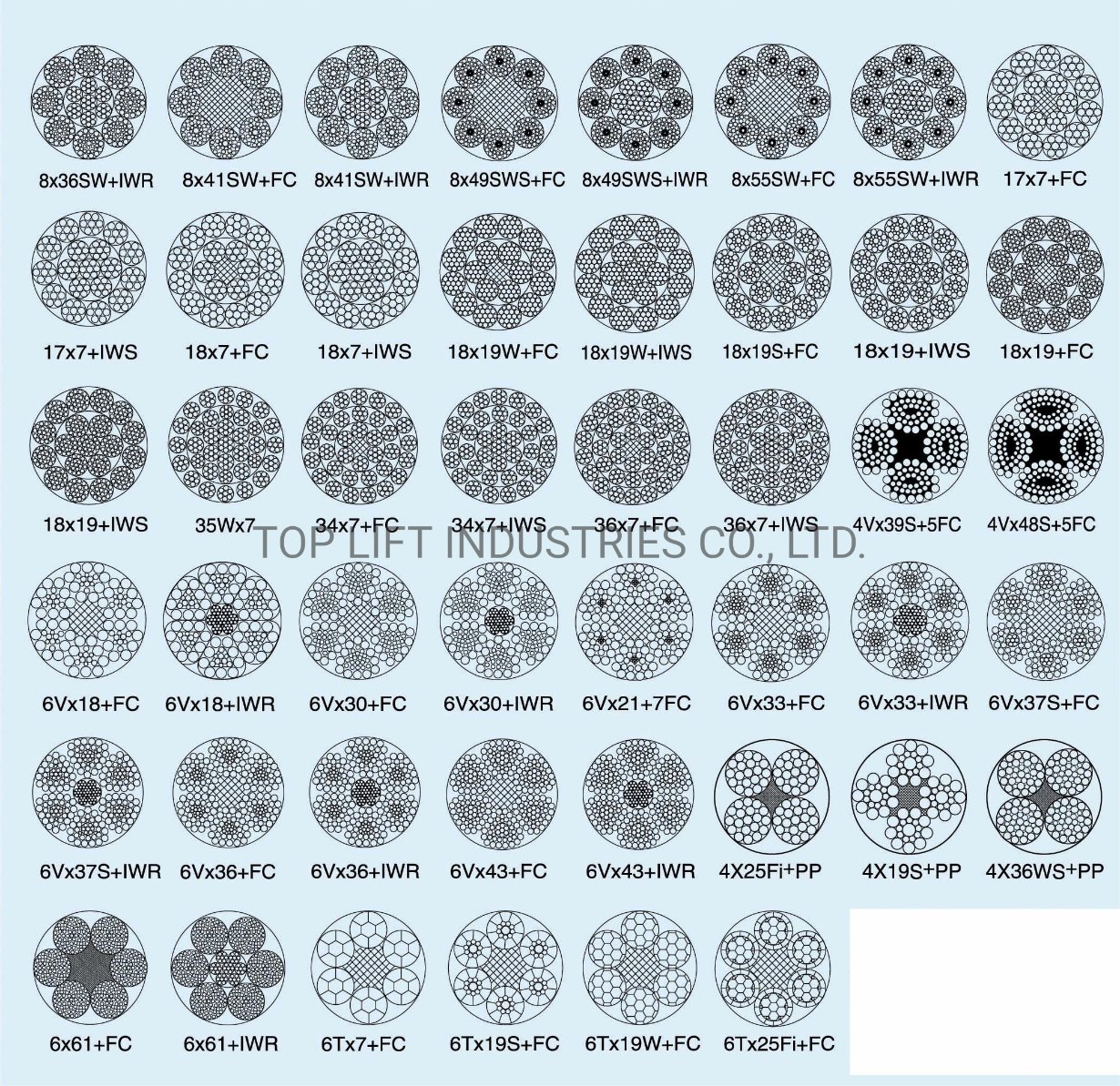

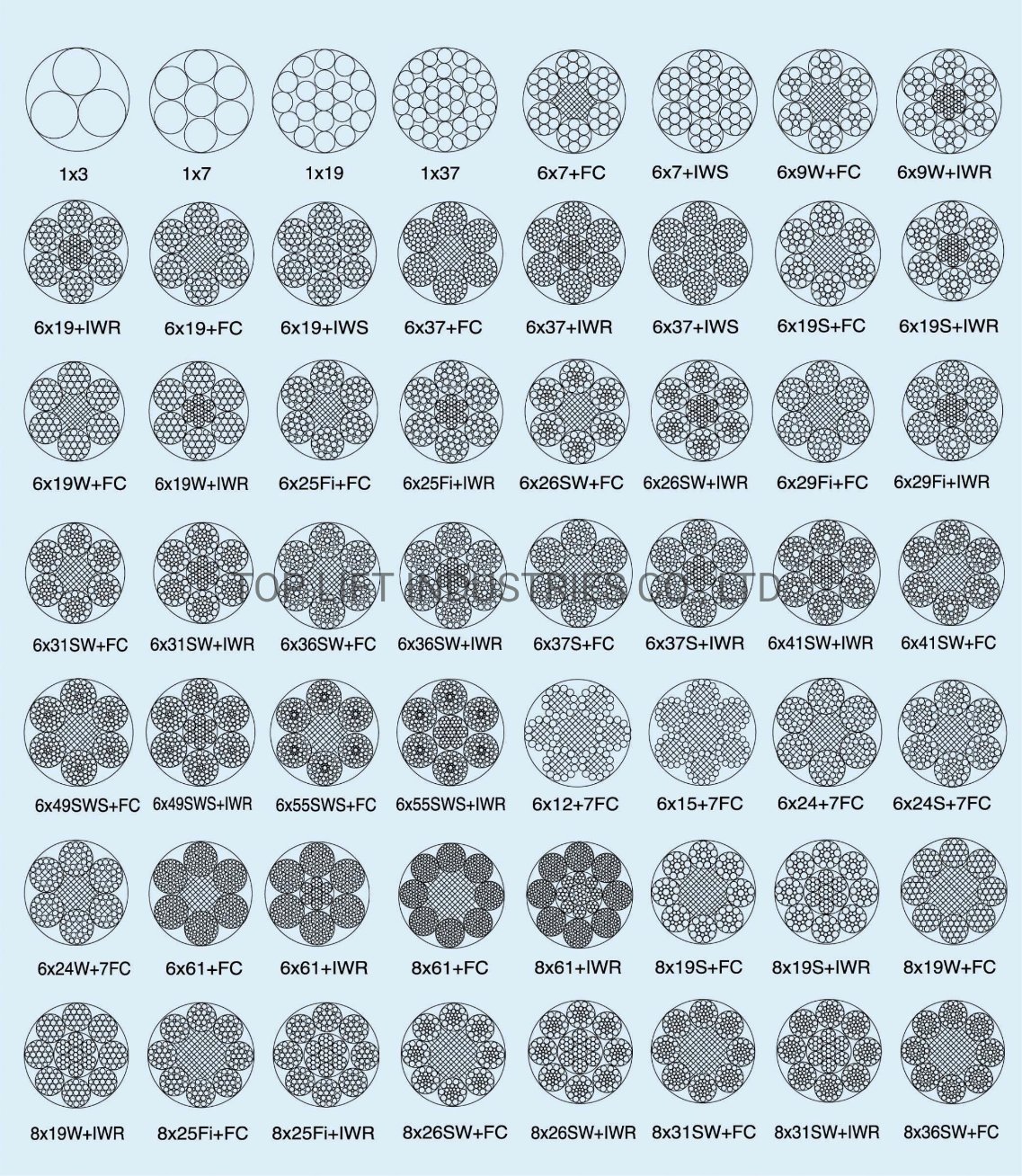

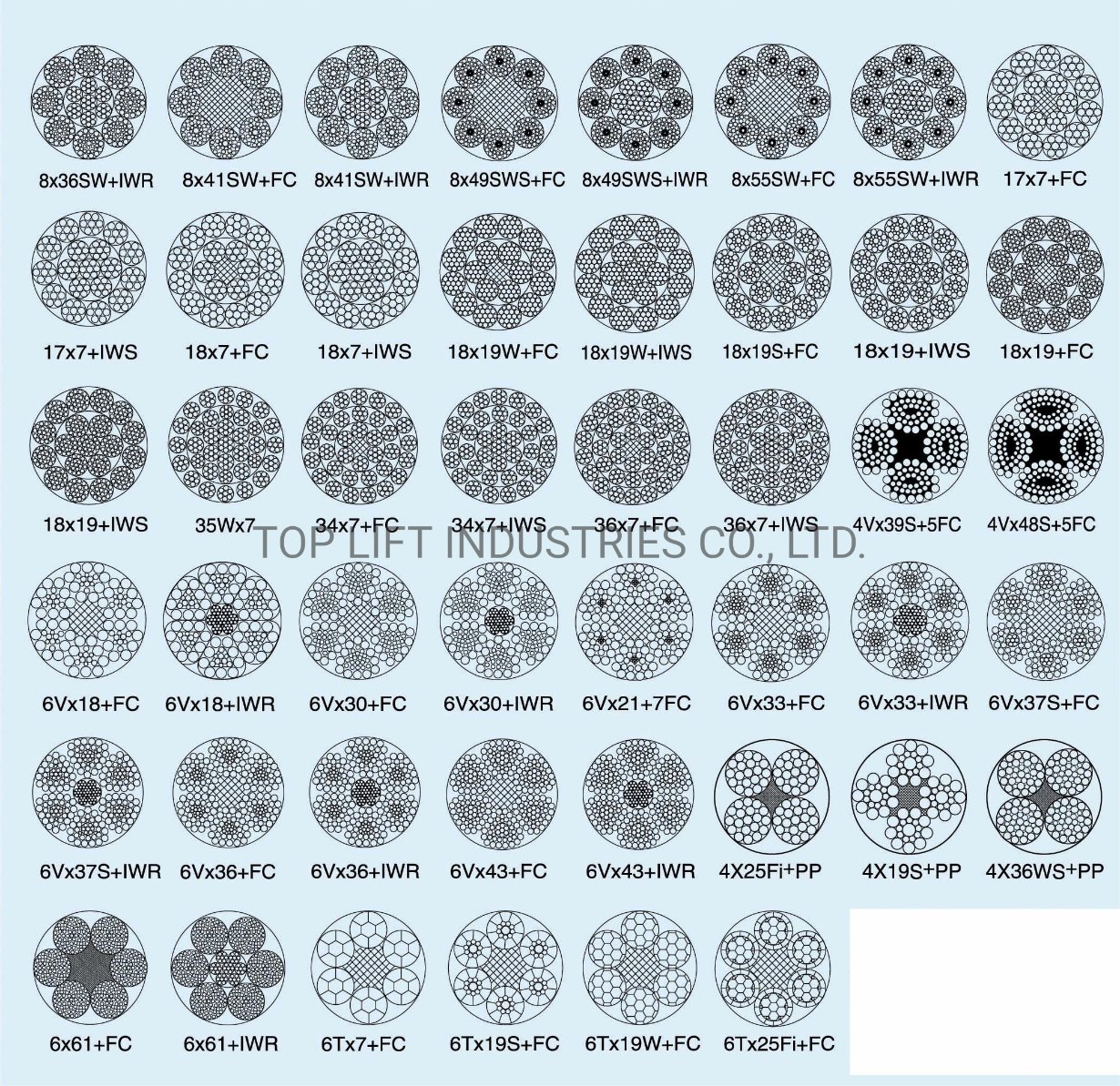

Wire rope is used to increase the support of suspension bridges, elevators, and as an additional reinforcement of towers. The design of wire rope, with its multiple strands wrapped around a stable core, provides strength, flexibility, and ease of handling for applications that have bending stress.

6X37+FC 6X37+WSC 6X37+IWRC

| Availability: | |

|---|---|

| Quantity: | |

The structural wire rope is a foundational component in industrial and construction applications, designed to deliver exceptional strength and stability for lifting, supporting, and securing heavy loads. Our high-strength wire rope is available in both galvanized wire rope and ungalvanized wire rope variants, with three core constructions: 6X37 FC, 6X37 WSC, and 6X37 IWRC. This versatility makes it a go-to choice for sectors such as construction, mining, bridge building, and marine operations, where reliability and durability are paramount. As a heavy-duty structural rope, it combines precision engineering with premium materials to meet the demands of even the most challenging projects.

Material | Carbon Steel |

Diameter Range | 5mm to 60mm |

Lay | Right interaction twist, Left interaction twist, Right direction twist, Left direction twist |

Tensile Strength | 1570/1670/ 1770/ 1870/1960KN |

Surface Treatment | Ungalvanized, Electro Galvanized, Hot Dip Galvanized, PVC Coated |

The 6X37 wire rope features a uniform, tightly twisted structure that enhances its stability and resistance to deformation. Each strand is meticulously braided to ensure even load distribution, reducing the risk of premature wear or failure. The FC wire rope (fibre core) boasts a soft, flexible core that absorbs shock, while the WSC wire rope (wire strand core) and IWRC wire rope (independent wire rope core) offer increased rigidity and strength for heavier loads.

The galvanized wire rope features a zinc coating that provides a bright, corrosion-resistant surface, visible as a smooth, metallic sheen. This finish protects the rope from moisture, rust, and environmental damage, making it ideal for outdoor or humid environments. In contrast, the ungalvanized wire rope retains its natural steel appearance—matte and rugged—suited for applications where galvanization may not be necessary or where a more discreet finish is preferred. Both variants maintain a consistent diameter and smooth surface, ensuring compatibility with pulleys, hooks, and other rigging equipment.

As a high-strength wire rope, it is crafted from premium steel wires that undergo rigorous drawing and heat treatment processes. The 6X37 structure and robust core options (FC, WSC, IWRC) enhance its load-bearing capacity, allowing it to handle heavy-duty tasks without compromising performance. The materials used resist wear, fatigue, and tensile stress, ensuring a long service life.

The galvanized wire rope’s zinc coating acts as a barrier against rust and corrosion, extending its lifespan in outdoor, marine, or humid environments. This advantage reduces maintenance costs and ensures reliability in harsh conditions where unprotected steel would degrade quickly.

Despite its strength, the 6X37 wire rope remains flexible enough for easy installation, winding, and maneuvering. This flexibility simplifies rigging tasks and reduces operator fatigue, while the uniform structure ensures smooth operation with lifting machinery.

With FC, WSC, and IWRC core choices, this structural wire rope adapts to diverse needs: the FC core is ideal for shock absorption and moderate loads, WSC offers balanced strength and flexibility, and IWRC delivers maximum rigidity for heavy loads and high-stress applications.

| Nom. Diam. (mm) | Nominal Tensile Strength of Rope | Approx. weight | ||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | kg/100m | |||||||

| KN | KN | KN | KN | KN | ||||||||

| FC | IWRC | FC | IWRC | FC | IWRC | FC | IWRC | FC | IWRC | |||

| 5 | 11.6 | 12.5 | 12.3 | 13.3 | 13.1 | 14.1 | 13.8 | 14.9 | 14.46 | 15.63 | 8.65 | 10 |

| 6 | 16.7 | 18 | 17.7 | 19.2 | 18.8 | 23 | 19.9 | 21.5 | 20.82 | 22.51 | 12.5 | 14.4 |

| 7 | 22.7 | 24.5 | 24.1 | 26.1 | 25.6 | 27.7 | 27 | 29.2 | 28.33 | 30.64 | 17 | 19.6 |

| 8 | 29.6 | 32.1 | 31.5 | 34.1 | 33.4 | 36.1 | 35.3 | 38.2 | 37 | 40.02 | 22.1 | 25.6 |

| 9 | 37.5 | 40.6 | 39.9 | 43.2 | 42.3 | 45.7 | 44.7 | 48.3 | 46.83 | 50.64 | 28 | 32.4 |

| 10 | 46.3 | 50.1 | 49.3 | 53.3 | 52.2 | 56.5 | 55.2 | 59.7 | 57.82 | 62.52 | 34.6 | 40 |

| 11 | 56 | 60.6 | 59.6 | 64.5 | 63.2 | 68.3 | 66.7 | 72.2 | 69.96 | 76.56 | 41.9 | 48.4 |

| 12 | 66.7 | 72.1 | 70.9 | 76.7 | 75.2 | 81.3 | 79.4 | 85.9 | 83.26 | 90.03 | 49.8 | 57.6 |

| 13 | 78.3 | 84.6 | 83.3 | 90 | 88.2 | 95.4 | 93.2 | 101 | 97.7 | 105.7 | 58.5 | 67.6 |

| 14 | 90.8 | 98.2 | 96.6 | 104 | 102 | 111 | 108 | 117 | 113 | 122.6 | 67.8 | 78.4 |

| 16 | 119 | 128 | 126 | 136 | 134 | 145 | 141 | 153 | 148 | 160.1 | 88.6 | 102 |

| 18 | 150 | 162 | 160 | 173 | 169 | 183 | 179 | 193 | 187.3 | 202.6 | 112 | 130 |

| 20 | 185 | 200 | 197 | 213 | 209 | 226 | 221 | 239 | 231.3 | 250.1 | 138 | 160 |

| 22 | 224 | 242 | 238 | 258 | 253 | 273 | 267 | 289 | 279.8 | 302.6 | 167 | 194 |

| 24 | 267 | 288 | 284 | 307 | 301 | 325 | 318 | 344 | 333 | 360 | 199 | 230 |

| 26 | 313 | 339 | 333 | 360 | 353 | 382 | 373 | 403 | 390.9 | 422.7 | 234 | 270 |

| 28 | 363 | 393 | 386 | 418 | 409 | 443 | 432 | 468 | 453.3 | 490.2 | 271 | 314 |

| 30 | 417 | 451 | 443 | 479 | 470 | 508 | 496 | 537 | 520.4 | 562.7 | 311 | 360 |

| 32 | 474 | 513 | 504 | 546 | 535 | 578 | 565 | 611 | 592.1 | 640.2 | 354 | 410 |

| 34 | 535 | 579 | 570 | 616 | 604 | 653 | 638 | 690 | 668.4 | 722.8 | 400 | 462 |

| 36 | 600 | 649 | 638 | 690 | 677 | 732 | 715 | 773 | 749.3 | 810.3 | 448 | 518 |

| 38 | 669 | 723 | 711 | 769 | 754 | 815 | 797 | 861 | 834.9 | 920.3 | 500 | 578 |

| 40 | 741 | 801 | 788 | 852 | 835 | 903 | 883 | 954 | 925 | 1000 | 554 | 640 |

| 42 | 817 | 883 | 869 | 940 | 921 | 996 | 973 | 1050 | 1020 | 1103 | 610 | 706 |

| 44 | 897 | 970 | 954 | 1030 | 1010 | 1090 | 1070 | 1150 | 1190 | 1210 | 670 | 774 |

| 46 | 980 | 1060 | 1040 | 1130 | 1100 | 1190 | 1170 | 1260 | 1221 | 1323 | 732 | 846 |

| 48 | 1070 | 1150 | 1140 | 1230 | 1200 | 1300 | 1270 | 1370 | 1331 | 1440 | 797 | 922 |

| 50 | 1160 | 1250 | 1230 | 1330 | 1305 | 1410 | 1380 | 1490 | 1445 | 1563 | 865 | 1000 |

| 52 | 1250 | 1350 | 1330 | 1440 | 1410 | 1530 | 1490 | 1610 | 1563 | 1691 | 936 | 1080 |

| 54 | 1350 | 1460 | 1440 | 1550 | 1520 | 1650 | 1610 | 1740 | 1686 | 1823 | 1010 | 1170 |

| 56 | 1450 | 1570 | 1540 | 1670 | 1640 | 1770 | 1730 | 1870 | 1813 | 1961 | 1090 | 1250 |

| 58 | 1560 | 1680 | 1660 | 1790 | 1760 | 1900 | 1860 | 2010 | 1945 | 2103 | 1160 | 1350 |

| 60 | 1670 | 1800 | 1770 | 1920 | 1880 | 2030 | 1990 | 2150 | 2082 | 2251 | 1250 | 1440 |

Our industrial wire rope is manufactured in accordance with global structural rope standards, ensuring consistency in dimensions, strength, and performance. Each batch is traceable, with detailed records of material sourcing and production processes. The product meets or exceeds requirements for tensile strength, fatigue resistance, and corrosion protection.

Every heavy-duty structural rope undergoes comprehensive testing, including tensile strength tests, twist balance inspections, and corrosion resistance assessments. Galvanized variants are checked for coating thickness and adhesion, while ungalvanized ropes are inspected for surface quality and structural integrity. These measures guarantee that each rope is free from defects and ready for demanding applications.

Galvanized wire rope features a zinc coating for corrosion resistance, making it suitable for outdoor, marine, or humid environments. Ungalvanized wire rope lacks this coating, offering a natural steel finish ideal for indoor applications or tasks where corrosion is not a concern. The choice depends on the working environment and durability requirements.

Choose FC wire rope for applications requiring flexibility and shock absorption (e.g., light to moderate lifting). WSC wire rope is ideal for balanced strength and flexibility (e.g., general rigging). IWRC wire rope offers maximum strength and rigidity (e.g., heavy lifting, structural support). Consider your load capacity and operational needs when selecting.

Regular maintenance includes inspecting for fraying, kinking, or corrosion, cleaning with a wire brush to remove debris, and lubricating with a specialized rope lubricant to reduce friction. Store the industrial wire rope in a dry, cool area away from sharp objects and direct sunlight. Replace the rope immediately if signs of damage are detected to avoid safety risks.

The structural wire rope is a foundational component in industrial and construction applications, designed to deliver exceptional strength and stability for lifting, supporting, and securing heavy loads. Our high-strength wire rope is available in both galvanized wire rope and ungalvanized wire rope variants, with three core constructions: 6X37 FC, 6X37 WSC, and 6X37 IWRC. This versatility makes it a go-to choice for sectors such as construction, mining, bridge building, and marine operations, where reliability and durability are paramount. As a heavy-duty structural rope, it combines precision engineering with premium materials to meet the demands of even the most challenging projects.

Material | Carbon Steel |

Diameter Range | 5mm to 60mm |

Lay | Right interaction twist, Left interaction twist, Right direction twist, Left direction twist |

Tensile Strength | 1570/1670/ 1770/ 1870/1960KN |

Surface Treatment | Ungalvanized, Electro Galvanized, Hot Dip Galvanized, PVC Coated |

The 6X37 wire rope features a uniform, tightly twisted structure that enhances its stability and resistance to deformation. Each strand is meticulously braided to ensure even load distribution, reducing the risk of premature wear or failure. The FC wire rope (fibre core) boasts a soft, flexible core that absorbs shock, while the WSC wire rope (wire strand core) and IWRC wire rope (independent wire rope core) offer increased rigidity and strength for heavier loads.

The galvanized wire rope features a zinc coating that provides a bright, corrosion-resistant surface, visible as a smooth, metallic sheen. This finish protects the rope from moisture, rust, and environmental damage, making it ideal for outdoor or humid environments. In contrast, the ungalvanized wire rope retains its natural steel appearance—matte and rugged—suited for applications where galvanization may not be necessary or where a more discreet finish is preferred. Both variants maintain a consistent diameter and smooth surface, ensuring compatibility with pulleys, hooks, and other rigging equipment.

As a high-strength wire rope, it is crafted from premium steel wires that undergo rigorous drawing and heat treatment processes. The 6X37 structure and robust core options (FC, WSC, IWRC) enhance its load-bearing capacity, allowing it to handle heavy-duty tasks without compromising performance. The materials used resist wear, fatigue, and tensile stress, ensuring a long service life.

The galvanized wire rope’s zinc coating acts as a barrier against rust and corrosion, extending its lifespan in outdoor, marine, or humid environments. This advantage reduces maintenance costs and ensures reliability in harsh conditions where unprotected steel would degrade quickly.

Despite its strength, the 6X37 wire rope remains flexible enough for easy installation, winding, and maneuvering. This flexibility simplifies rigging tasks and reduces operator fatigue, while the uniform structure ensures smooth operation with lifting machinery.

With FC, WSC, and IWRC core choices, this structural wire rope adapts to diverse needs: the FC core is ideal for shock absorption and moderate loads, WSC offers balanced strength and flexibility, and IWRC delivers maximum rigidity for heavy loads and high-stress applications.

| Nom. Diam. (mm) | Nominal Tensile Strength of Rope | Approx. weight | ||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | kg/100m | |||||||

| KN | KN | KN | KN | KN | ||||||||

| FC | IWRC | FC | IWRC | FC | IWRC | FC | IWRC | FC | IWRC | |||

| 5 | 11.6 | 12.5 | 12.3 | 13.3 | 13.1 | 14.1 | 13.8 | 14.9 | 14.46 | 15.63 | 8.65 | 10 |

| 6 | 16.7 | 18 | 17.7 | 19.2 | 18.8 | 23 | 19.9 | 21.5 | 20.82 | 22.51 | 12.5 | 14.4 |

| 7 | 22.7 | 24.5 | 24.1 | 26.1 | 25.6 | 27.7 | 27 | 29.2 | 28.33 | 30.64 | 17 | 19.6 |

| 8 | 29.6 | 32.1 | 31.5 | 34.1 | 33.4 | 36.1 | 35.3 | 38.2 | 37 | 40.02 | 22.1 | 25.6 |

| 9 | 37.5 | 40.6 | 39.9 | 43.2 | 42.3 | 45.7 | 44.7 | 48.3 | 46.83 | 50.64 | 28 | 32.4 |

| 10 | 46.3 | 50.1 | 49.3 | 53.3 | 52.2 | 56.5 | 55.2 | 59.7 | 57.82 | 62.52 | 34.6 | 40 |

| 11 | 56 | 60.6 | 59.6 | 64.5 | 63.2 | 68.3 | 66.7 | 72.2 | 69.96 | 76.56 | 41.9 | 48.4 |

| 12 | 66.7 | 72.1 | 70.9 | 76.7 | 75.2 | 81.3 | 79.4 | 85.9 | 83.26 | 90.03 | 49.8 | 57.6 |

| 13 | 78.3 | 84.6 | 83.3 | 90 | 88.2 | 95.4 | 93.2 | 101 | 97.7 | 105.7 | 58.5 | 67.6 |

| 14 | 90.8 | 98.2 | 96.6 | 104 | 102 | 111 | 108 | 117 | 113 | 122.6 | 67.8 | 78.4 |

| 16 | 119 | 128 | 126 | 136 | 134 | 145 | 141 | 153 | 148 | 160.1 | 88.6 | 102 |

| 18 | 150 | 162 | 160 | 173 | 169 | 183 | 179 | 193 | 187.3 | 202.6 | 112 | 130 |

| 20 | 185 | 200 | 197 | 213 | 209 | 226 | 221 | 239 | 231.3 | 250.1 | 138 | 160 |

| 22 | 224 | 242 | 238 | 258 | 253 | 273 | 267 | 289 | 279.8 | 302.6 | 167 | 194 |

| 24 | 267 | 288 | 284 | 307 | 301 | 325 | 318 | 344 | 333 | 360 | 199 | 230 |

| 26 | 313 | 339 | 333 | 360 | 353 | 382 | 373 | 403 | 390.9 | 422.7 | 234 | 270 |

| 28 | 363 | 393 | 386 | 418 | 409 | 443 | 432 | 468 | 453.3 | 490.2 | 271 | 314 |

| 30 | 417 | 451 | 443 | 479 | 470 | 508 | 496 | 537 | 520.4 | 562.7 | 311 | 360 |

| 32 | 474 | 513 | 504 | 546 | 535 | 578 | 565 | 611 | 592.1 | 640.2 | 354 | 410 |

| 34 | 535 | 579 | 570 | 616 | 604 | 653 | 638 | 690 | 668.4 | 722.8 | 400 | 462 |

| 36 | 600 | 649 | 638 | 690 | 677 | 732 | 715 | 773 | 749.3 | 810.3 | 448 | 518 |

| 38 | 669 | 723 | 711 | 769 | 754 | 815 | 797 | 861 | 834.9 | 920.3 | 500 | 578 |

| 40 | 741 | 801 | 788 | 852 | 835 | 903 | 883 | 954 | 925 | 1000 | 554 | 640 |

| 42 | 817 | 883 | 869 | 940 | 921 | 996 | 973 | 1050 | 1020 | 1103 | 610 | 706 |

| 44 | 897 | 970 | 954 | 1030 | 1010 | 1090 | 1070 | 1150 | 1190 | 1210 | 670 | 774 |

| 46 | 980 | 1060 | 1040 | 1130 | 1100 | 1190 | 1170 | 1260 | 1221 | 1323 | 732 | 846 |

| 48 | 1070 | 1150 | 1140 | 1230 | 1200 | 1300 | 1270 | 1370 | 1331 | 1440 | 797 | 922 |

| 50 | 1160 | 1250 | 1230 | 1330 | 1305 | 1410 | 1380 | 1490 | 1445 | 1563 | 865 | 1000 |

| 52 | 1250 | 1350 | 1330 | 1440 | 1410 | 1530 | 1490 | 1610 | 1563 | 1691 | 936 | 1080 |

| 54 | 1350 | 1460 | 1440 | 1550 | 1520 | 1650 | 1610 | 1740 | 1686 | 1823 | 1010 | 1170 |

| 56 | 1450 | 1570 | 1540 | 1670 | 1640 | 1770 | 1730 | 1870 | 1813 | 1961 | 1090 | 1250 |

| 58 | 1560 | 1680 | 1660 | 1790 | 1760 | 1900 | 1860 | 2010 | 1945 | 2103 | 1160 | 1350 |

| 60 | 1670 | 1800 | 1770 | 1920 | 1880 | 2030 | 1990 | 2150 | 2082 | 2251 | 1250 | 1440 |

Our industrial wire rope is manufactured in accordance with global structural rope standards, ensuring consistency in dimensions, strength, and performance. Each batch is traceable, with detailed records of material sourcing and production processes. The product meets or exceeds requirements for tensile strength, fatigue resistance, and corrosion protection.

Every heavy-duty structural rope undergoes comprehensive testing, including tensile strength tests, twist balance inspections, and corrosion resistance assessments. Galvanized variants are checked for coating thickness and adhesion, while ungalvanized ropes are inspected for surface quality and structural integrity. These measures guarantee that each rope is free from defects and ready for demanding applications.

Galvanized wire rope features a zinc coating for corrosion resistance, making it suitable for outdoor, marine, or humid environments. Ungalvanized wire rope lacks this coating, offering a natural steel finish ideal for indoor applications or tasks where corrosion is not a concern. The choice depends on the working environment and durability requirements.

Choose FC wire rope for applications requiring flexibility and shock absorption (e.g., light to moderate lifting). WSC wire rope is ideal for balanced strength and flexibility (e.g., general rigging). IWRC wire rope offers maximum strength and rigidity (e.g., heavy lifting, structural support). Consider your load capacity and operational needs when selecting.

Regular maintenance includes inspecting for fraying, kinking, or corrosion, cleaning with a wire brush to remove debris, and lubricating with a specialized rope lubricant to reduce friction. Store the industrial wire rope in a dry, cool area away from sharp objects and direct sunlight. Replace the rope immediately if signs of damage are detected to avoid safety risks.