- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

6X15+7FC

| Availability: | |

|---|---|

| Quantity: | |

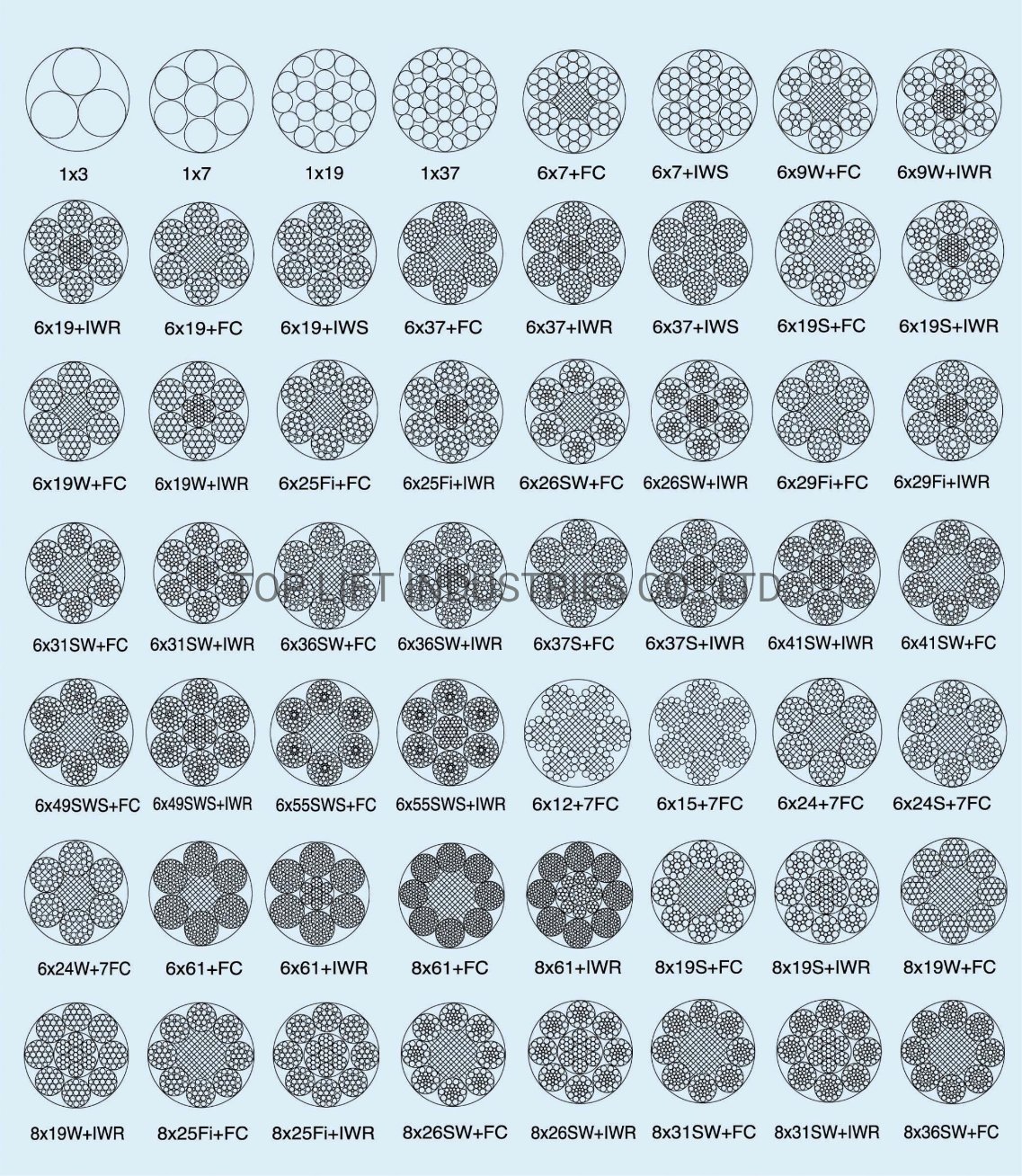

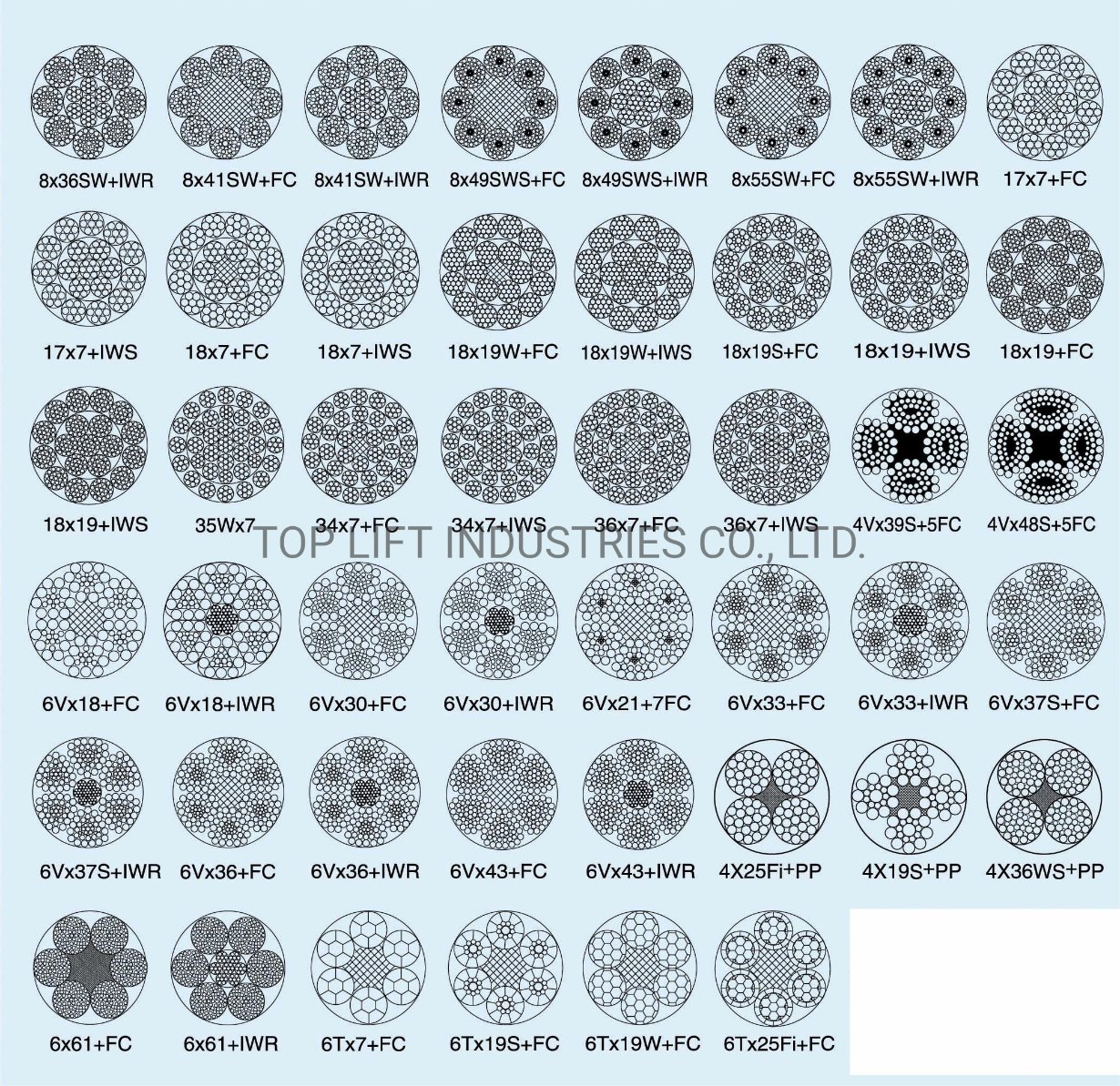

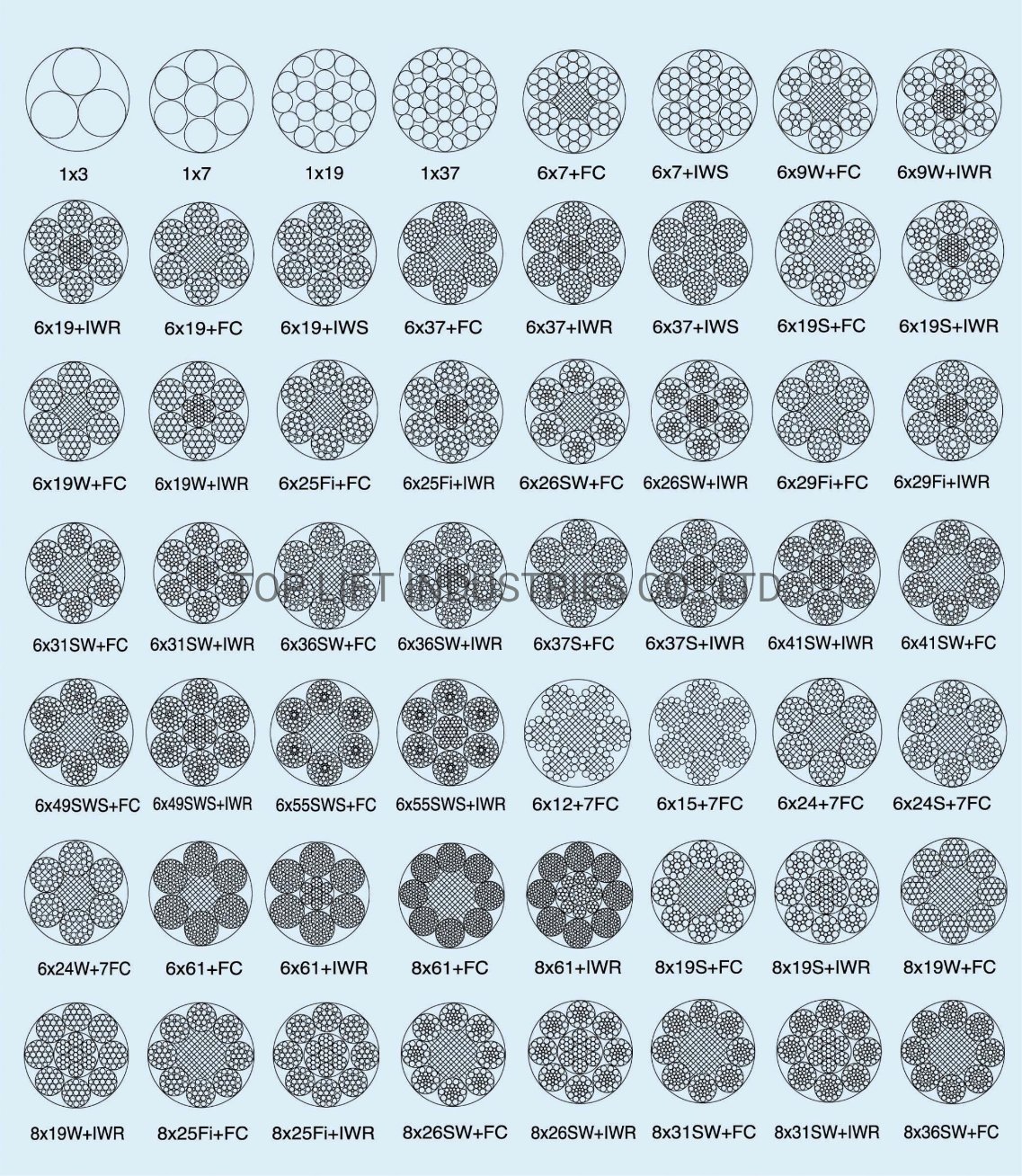

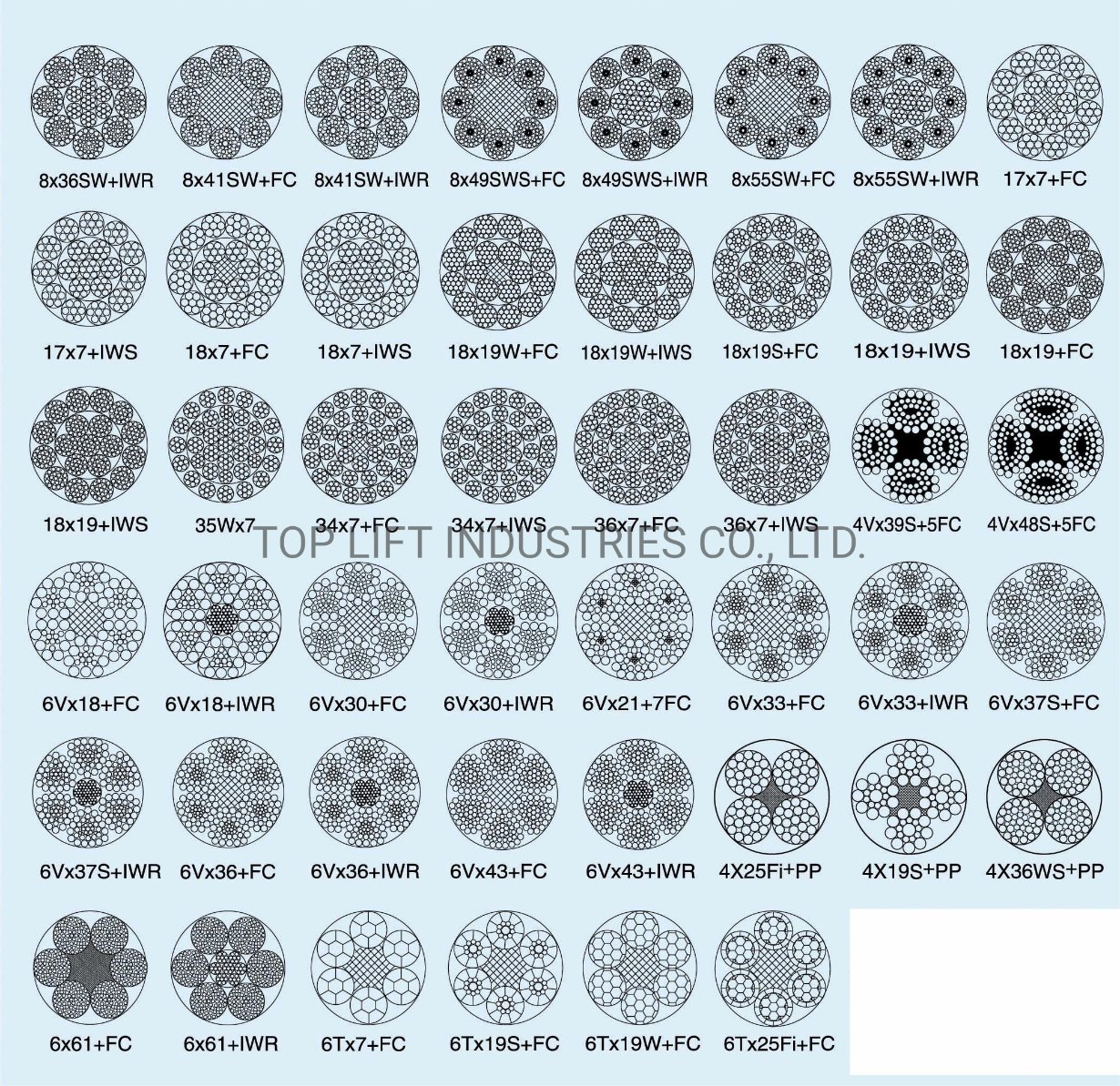

The steel wire rope 6X15-7FC is a versatile lifting solution designed for a wide range of industrial applications, including material handling, construction hoisting, logistics transportation, and mechanical traction. Available in two variants—electric galvanized steel wire rope and ungalvanized steel wire rope—it caters to diverse environmental and operational needs. The 6X15-7FC structure, featuring 6 strands of 15 wires each with a 7FC fiber core, delivers balanced performance, making it a reliable choice for both indoor and outdoor projects. Whether you’re lifting heavy components in a manufacturing plant or securing loads for long-distance transport, this 6X15-7FC steel wire rope combines strength and adaptability to meet rigorous work demands.

The steel wire rope boasts a precision-engineered 6X15-7FC structure that ensures uniform force distribution across all strands. Each strand is tightly twisted to form a cohesive unit, while the 7FC fiber core enhances flexibility and reduces fatigue during repeated use. The electric galvanized steel wire rope features a smooth, shiny zinc coating that not only improves corrosion resistance but also gives it a clean, professional finish. In contrast, the ungalvanized steel wire rope retains its natural metal texture, ideal for applications where a raw, uncoated surface is preferred for specific connections or compatibility.

Both variants have a consistent diameter throughout the length, with no irregularities or weak points. The wire ends are neatly finished to prevent fraying, and the entire rope maintains a straight, stable form when under tension. The 6X15-7FC structure is visually distinguishable by its balanced strand arrangement, which contributes to its sleek, functional appearance. Whether coiled for storage or stretched during lifting, the rope maintains its structural integrity, reflecting meticulous manufacturing standards.

Nominal Diameter | Approx.Weight | Nominal Tensile Strength of Rope | (MPa) | |||

1570 | 1670 | 1770 | ||||

D | Allowed | NF | SF | Minimum Breaking Load ofRope | ||

mm | % | kg/100m | KN | |||

5 | 5.75 | 5.32 | 7.00 | 7.50 | 7.90 | |

8 | 14.72 | 13.63 | 18.10 | 19.20 | 20.40 | |

10 | 23.00 | 21.30 | 28.30 | 30.10 | 31.90 | |

12 | 33.10 | 30.67 | 40.70 | 43.30 | 45.90 | |

14 | 45.10 | 41.75 | 55.40 | 58.90 | 62.40 | |

16 | 58.90 | 54.52 | 72.30 | 77.00 | 81.60 | |

18 | 74.50 | 69.00 | 91.60 | 97.40 | 103.00 | |

20 | +7 | 92.00 | 85.20 | 113.00 | 120.00 | 127.00 |

22 | 0 | 111.00 | 103.10 | 137.00 | 145.00 | 154.00 |

24 | 132.40 | 123.00 | 163.00 | 173.00 | 184.00 | |

26 | 155.50 | 144.00 | 191.00 | 203.00 | 215.00 | |

28 | 180.30 | 167.00 | 222.00 | 236.00 | 250.00 | |

30 | 207.00 | 192.00 | 254.00 | 271.00 | 287.00 | |

32 | 235.00 | 218.00 | 289.00 | 308.00 | 326.00 | |

34 | 256.00 | 246.90 | 327.00 | 350.00 | 370.00 | |

36 | 298.00 | 276.00 | 370.00 | 390.00 | 410.00 | |

The 6X15-7FC configuration is the backbone of this steel wire rope’s reliability. The 6 strands work in harmony with the 7FC fiber core to resist twisting and kinking, even when navigating tight angles or heavy loads. This stability minimizes the risk of unexpected failures, making it a trusted choice for critical lifting tasks.

The electric galvanized steel wire rope offers superior protection against moisture, rust, and chemical exposure, perfect for outdoor or humid environments like construction sites or marine applications. The ungalvanized steel wire rope, on the other hand, is ideal for indoor use or projects where coating compatibility is a concern, providing a cost-effective yet durable option.

Crafted from high-quality carbon steel, the wire rope balances flexibility with raw strength. The tightly twisted strands and robust fiber core work together to handle heavy loads without compromising performance, ensuring consistent lifting power across its service life.

Resistant to wear, abrasion, and mechanical stress, this 6X15-7FC steel wire rope withstands the rigors of daily industrial use. The materials and manufacturing process reduce the risk of wire breakage or core damage, extending the rope’s lifespan and reducing replacement costs.

We adhere to international lifting equipment standards to ensure every steel wire rope 6X15-7FC meets strict quality criteria. Each batch undergoes rigorous testing, including tensile strength checks, flexibility assessments, and corrosion resistance evaluations (for galvanized variants). The raw steel used is sourced from reputable suppliers, and the manufacturing process is monitored by quality control experts to eliminate defects. Additionally, the rope is designed to resist fatigue from repeated bending and lifting, ensuring long-term reliability in demanding work environments.

The electric galvanized steel wire rope is ideal for outdoor, humid, or corrosive environments (e.g., construction sites, docks, or chemical plants) thanks to its zinc coating. The ungalvanized steel wire rope performs best in dry indoor settings, such as warehouses or manufacturing facilities, where corrosion risk is low and coating compatibility is key.

Regularly inspect the rope for fraying, kinking, or signs of corrosion. For electric galvanized steel wire rope, wipe away moisture and debris after use to preserve the zinc coating. Avoid sharp bends or overloading, as these can damage the strands or fiber core. Store the rope in a dry, well-ventilated area to prevent rust.

Yes, the 6X15-7FC steel wire rope is specifically designed for overhead lifting, provided it is used within its recommended load limits. Its structural stability and load-bearing capacity make it suitable for lifting heavy materials, equipment, and components in construction, manufacturing, and logistics settings.

The steel wire rope 6X15-7FC is a versatile lifting solution designed for a wide range of industrial applications, including material handling, construction hoisting, logistics transportation, and mechanical traction. Available in two variants—electric galvanized steel wire rope and ungalvanized steel wire rope—it caters to diverse environmental and operational needs. The 6X15-7FC structure, featuring 6 strands of 15 wires each with a 7FC fiber core, delivers balanced performance, making it a reliable choice for both indoor and outdoor projects. Whether you’re lifting heavy components in a manufacturing plant or securing loads for long-distance transport, this 6X15-7FC steel wire rope combines strength and adaptability to meet rigorous work demands.

The steel wire rope boasts a precision-engineered 6X15-7FC structure that ensures uniform force distribution across all strands. Each strand is tightly twisted to form a cohesive unit, while the 7FC fiber core enhances flexibility and reduces fatigue during repeated use. The electric galvanized steel wire rope features a smooth, shiny zinc coating that not only improves corrosion resistance but also gives it a clean, professional finish. In contrast, the ungalvanized steel wire rope retains its natural metal texture, ideal for applications where a raw, uncoated surface is preferred for specific connections or compatibility.

Both variants have a consistent diameter throughout the length, with no irregularities or weak points. The wire ends are neatly finished to prevent fraying, and the entire rope maintains a straight, stable form when under tension. The 6X15-7FC structure is visually distinguishable by its balanced strand arrangement, which contributes to its sleek, functional appearance. Whether coiled for storage or stretched during lifting, the rope maintains its structural integrity, reflecting meticulous manufacturing standards.

Nominal Diameter | Approx.Weight | Nominal Tensile Strength of Rope | (MPa) | |||

1570 | 1670 | 1770 | ||||

D | Allowed | NF | SF | Minimum Breaking Load ofRope | ||

mm | % | kg/100m | KN | |||

5 | 5.75 | 5.32 | 7.00 | 7.50 | 7.90 | |

8 | 14.72 | 13.63 | 18.10 | 19.20 | 20.40 | |

10 | 23.00 | 21.30 | 28.30 | 30.10 | 31.90 | |

12 | 33.10 | 30.67 | 40.70 | 43.30 | 45.90 | |

14 | 45.10 | 41.75 | 55.40 | 58.90 | 62.40 | |

16 | 58.90 | 54.52 | 72.30 | 77.00 | 81.60 | |

18 | 74.50 | 69.00 | 91.60 | 97.40 | 103.00 | |

20 | +7 | 92.00 | 85.20 | 113.00 | 120.00 | 127.00 |

22 | 0 | 111.00 | 103.10 | 137.00 | 145.00 | 154.00 |

24 | 132.40 | 123.00 | 163.00 | 173.00 | 184.00 | |

26 | 155.50 | 144.00 | 191.00 | 203.00 | 215.00 | |

28 | 180.30 | 167.00 | 222.00 | 236.00 | 250.00 | |

30 | 207.00 | 192.00 | 254.00 | 271.00 | 287.00 | |

32 | 235.00 | 218.00 | 289.00 | 308.00 | 326.00 | |

34 | 256.00 | 246.90 | 327.00 | 350.00 | 370.00 | |

36 | 298.00 | 276.00 | 370.00 | 390.00 | 410.00 | |

The 6X15-7FC configuration is the backbone of this steel wire rope’s reliability. The 6 strands work in harmony with the 7FC fiber core to resist twisting and kinking, even when navigating tight angles or heavy loads. This stability minimizes the risk of unexpected failures, making it a trusted choice for critical lifting tasks.

The electric galvanized steel wire rope offers superior protection against moisture, rust, and chemical exposure, perfect for outdoor or humid environments like construction sites or marine applications. The ungalvanized steel wire rope, on the other hand, is ideal for indoor use or projects where coating compatibility is a concern, providing a cost-effective yet durable option.

Crafted from high-quality carbon steel, the wire rope balances flexibility with raw strength. The tightly twisted strands and robust fiber core work together to handle heavy loads without compromising performance, ensuring consistent lifting power across its service life.

Resistant to wear, abrasion, and mechanical stress, this 6X15-7FC steel wire rope withstands the rigors of daily industrial use. The materials and manufacturing process reduce the risk of wire breakage or core damage, extending the rope’s lifespan and reducing replacement costs.

We adhere to international lifting equipment standards to ensure every steel wire rope 6X15-7FC meets strict quality criteria. Each batch undergoes rigorous testing, including tensile strength checks, flexibility assessments, and corrosion resistance evaluations (for galvanized variants). The raw steel used is sourced from reputable suppliers, and the manufacturing process is monitored by quality control experts to eliminate defects. Additionally, the rope is designed to resist fatigue from repeated bending and lifting, ensuring long-term reliability in demanding work environments.

The electric galvanized steel wire rope is ideal for outdoor, humid, or corrosive environments (e.g., construction sites, docks, or chemical plants) thanks to its zinc coating. The ungalvanized steel wire rope performs best in dry indoor settings, such as warehouses or manufacturing facilities, where corrosion risk is low and coating compatibility is key.

Regularly inspect the rope for fraying, kinking, or signs of corrosion. For electric galvanized steel wire rope, wipe away moisture and debris after use to preserve the zinc coating. Avoid sharp bends or overloading, as these can damage the strands or fiber core. Store the rope in a dry, well-ventilated area to prevent rust.

Yes, the 6X15-7FC steel wire rope is specifically designed for overhead lifting, provided it is used within its recommended load limits. Its structural stability and load-bearing capacity make it suitable for lifting heavy materials, equipment, and components in construction, manufacturing, and logistics settings.