- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

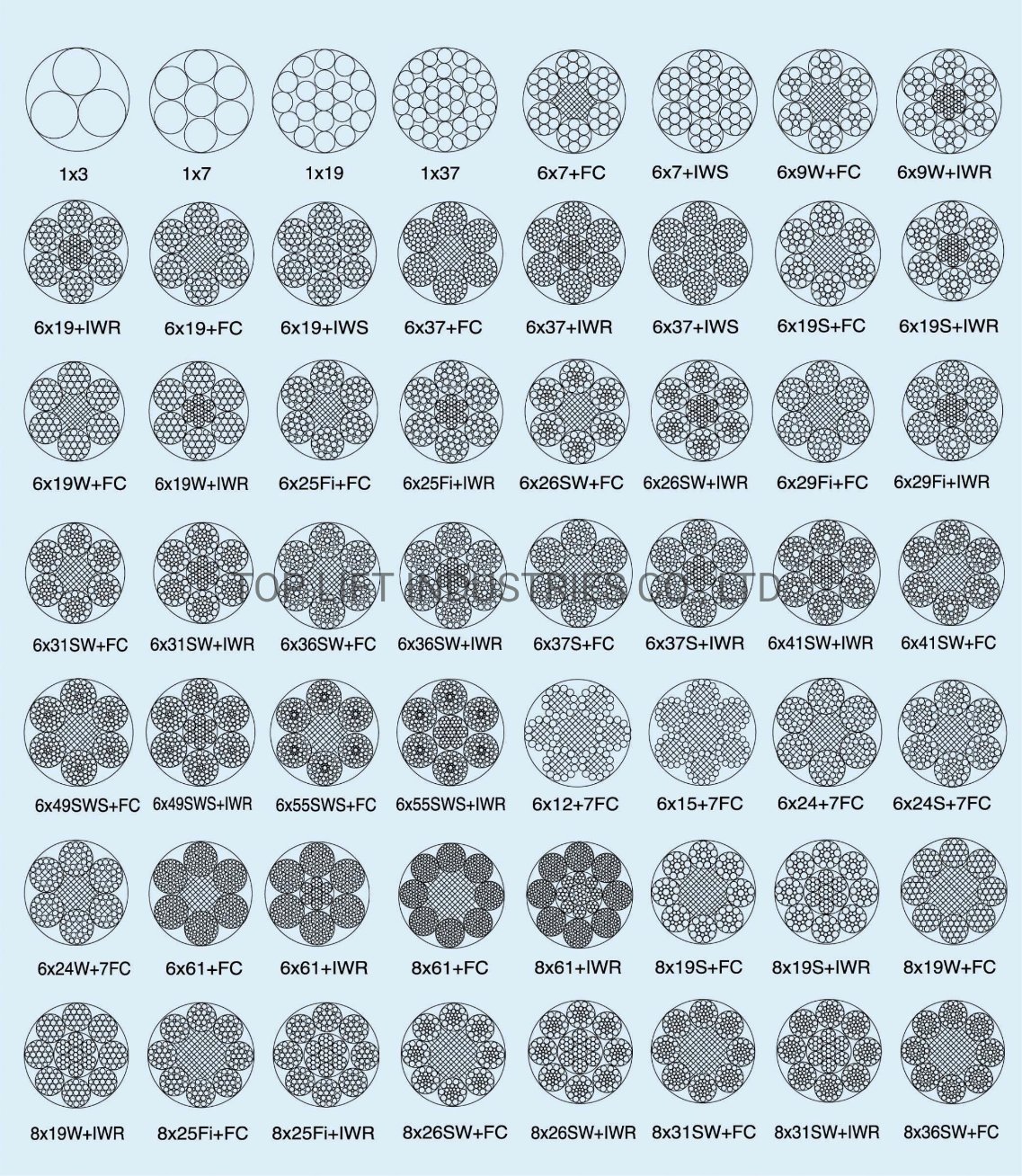

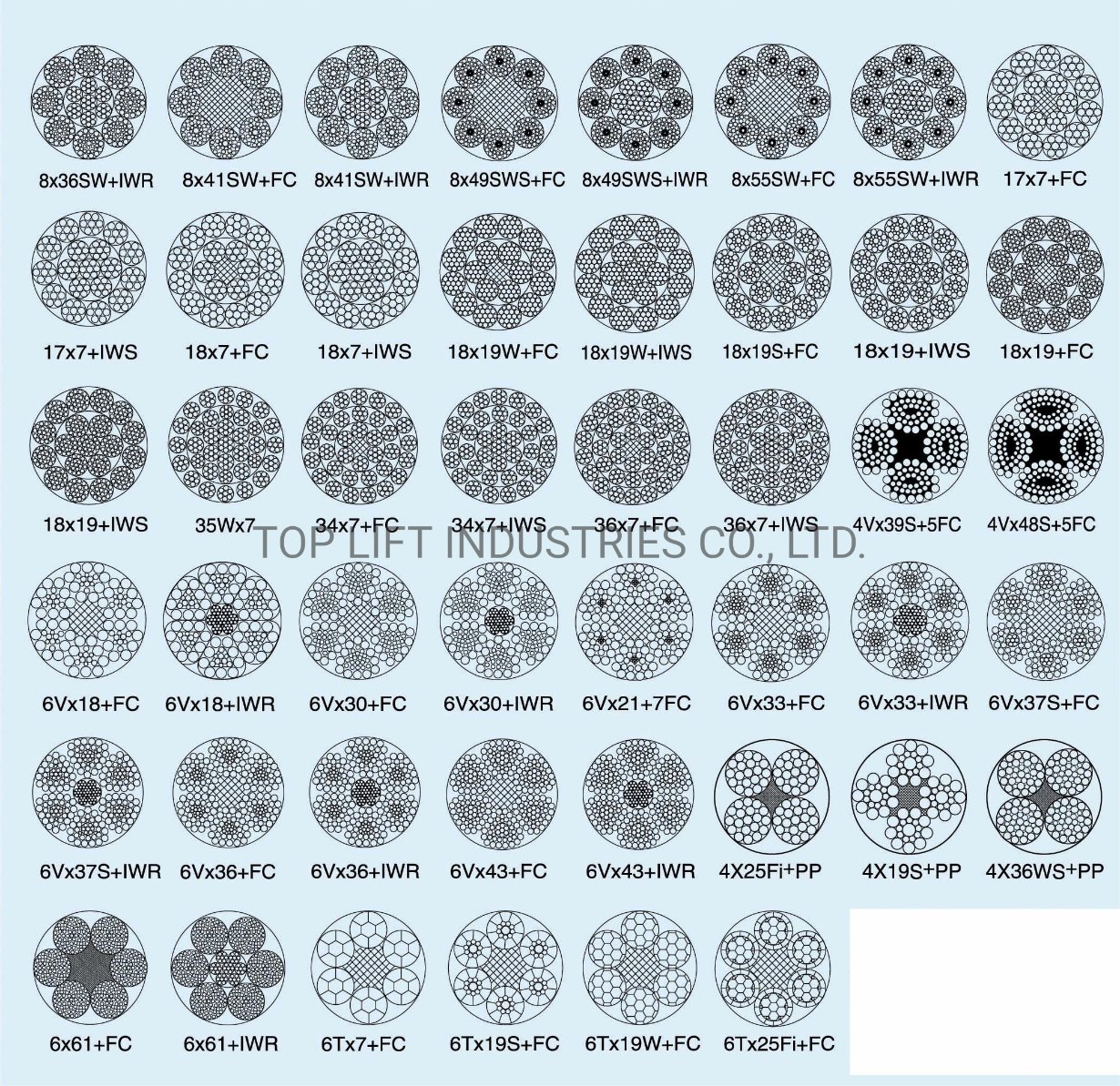

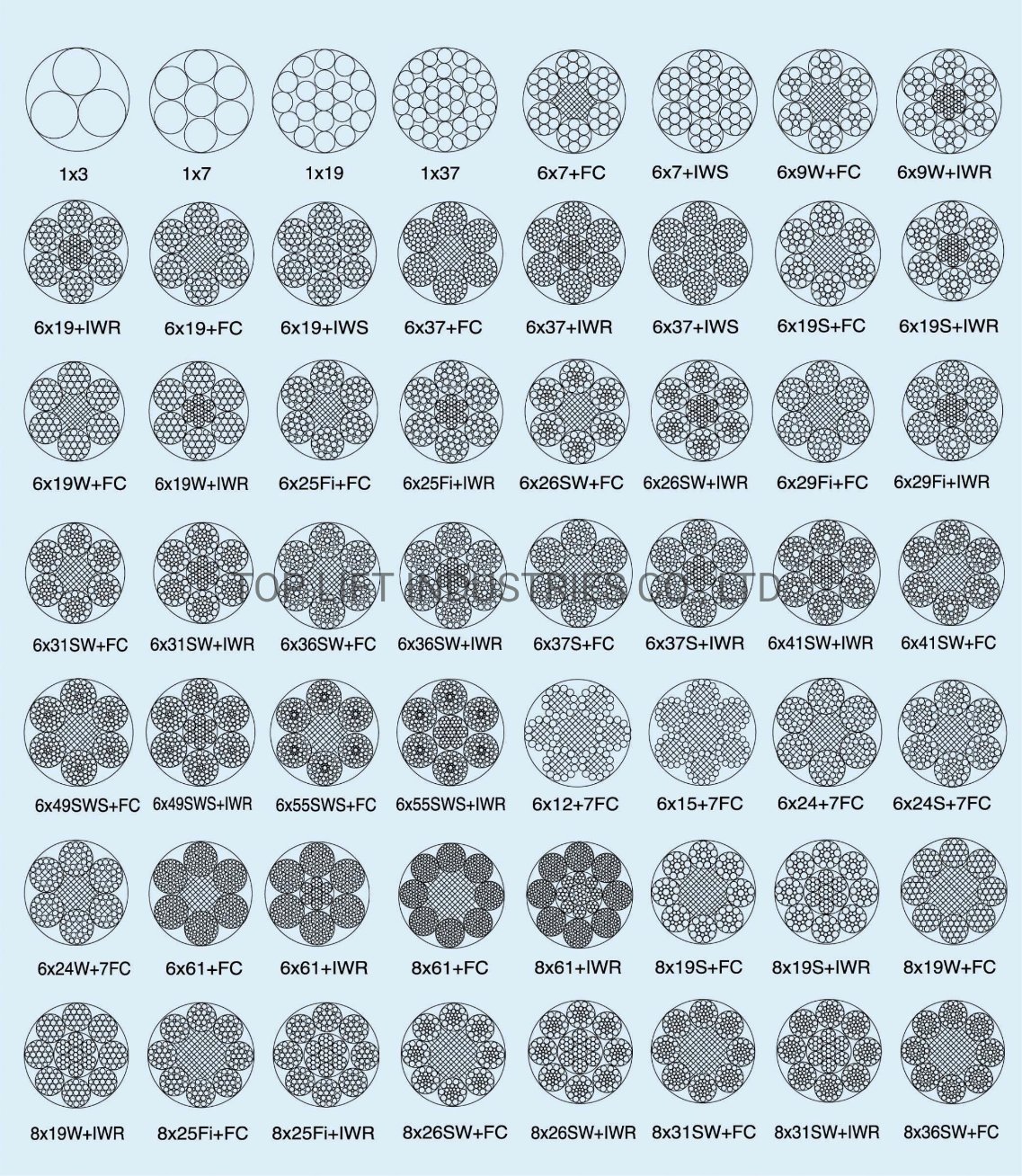

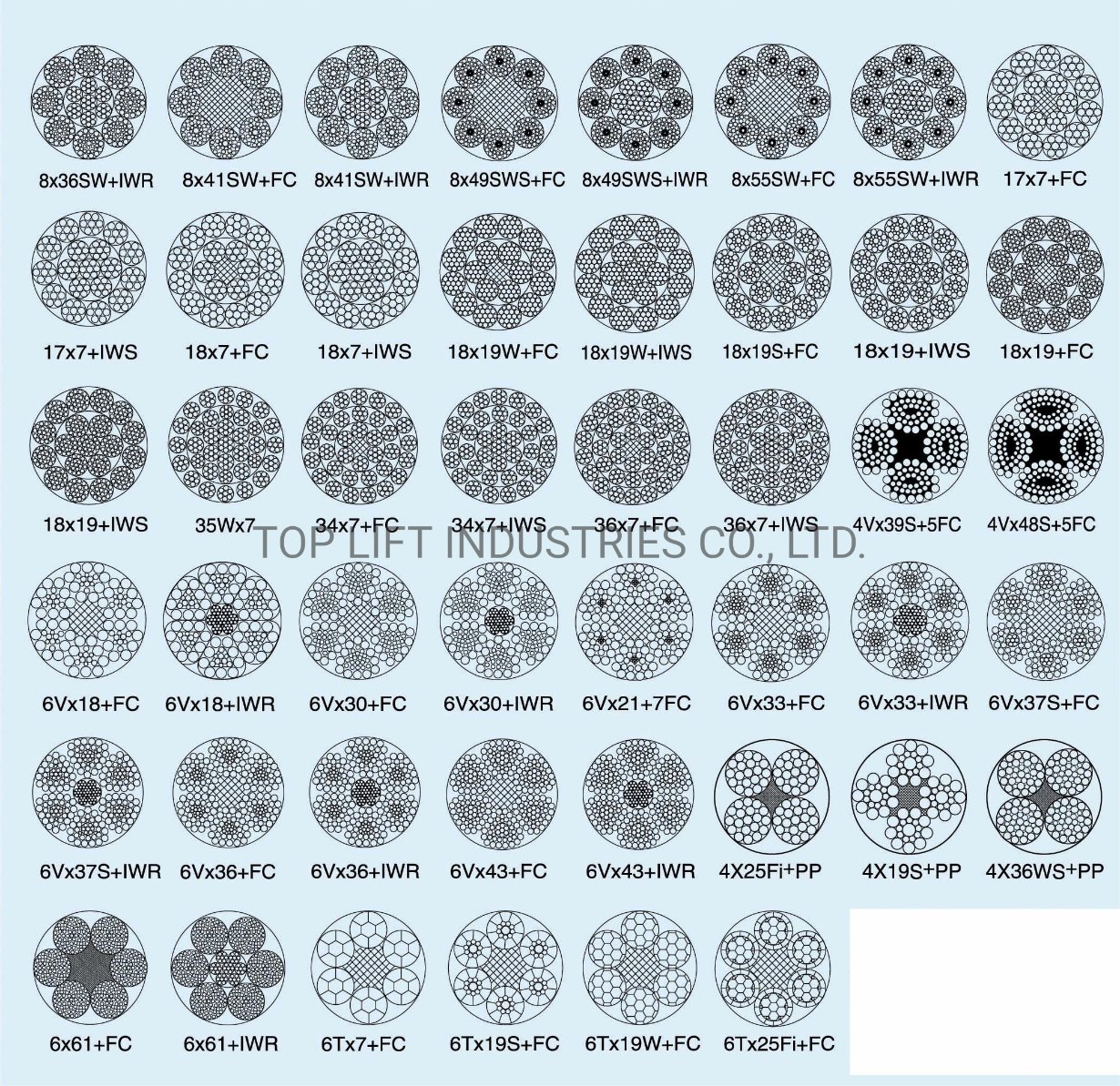

Wire rope is employed to enhance the support of suspension bridges, elevators, and to reinforce towers. Its design, featuring multiple strands wound around a central core, offers a combination of strength, flexibility, and ease of handling, making it ideal for applications subject to bending stress.

8X61+FC 8X61+IWR

| Availability: | |

|---|---|

| Quantity: | |

The Certified Zip Line Cable (9.1MM) is a premium Galvanized Steel Wire Rope engineered for zip line installations, light-duty lifting, and suspended systems that prioritize safety and long-term reliability. Made from high-grade steel, this wire rope adheres to strict industry certifications, ensuring it performs consistently in both indoor recreational setups and outdoor industrial environments. Whether you’re building a backyard zip line or equipping a commercial adventure park, this steel wire rope delivers the stability needed to support regular use without compromising on safety. Its 9.1MM diameter strikes a perfect balance between flexibility and strength, making it suitable for diverse applications where a durable, corrosion-resistant cable is essential.

| Product Name | steel wire rope | |||

| Raw material | quality carbon steel | |||

| Standard | ISO, DIN, ASTM, GB, etc. | |||

| Construction | 8X61+FC 8X61+IWR | |||

| Features | Steel Cables have smooth surface, high corrosion resistant, high fatigue strength, excellent heat resistance and are free from Lateral / longitudinal cracks, pits and marks etc | |||

| Range of products | (Galvanized, Ungalvanized, coated PVC /PE )steel wire rope Hot dip galvanized steel wire rope, etc | |||

| Packing | plastic wheel, solid wood wheel, plywood wheel, coils, bag, etc | |||

The 9.1MM Galvanized Steel Wire Rope boasts a smooth, uniform surface with a bright zinc coating that enhances its visual appeal while forming a protective barrier against environmental damage. Its flexible strand construction allows it to bend easily around pulleys and anchors without kinking— a key feature for zip line systems that require smooth, uninterrupted movement. Unlike ungalvanized alternatives, the rope has no rough edges or uneven spots, ensuring consistent contact with hardware and reducing wear over time. It is supplied in a tangle-free form, with a sleek profile that simplifies handling during installation. The galvanized finish gives the rope a professional look, making it suitable for both functional and aesthetically focused projects.

The galvanized coating on this wire rope acts as a shield against moisture, salt, and corrosive chemicals, making it ideal for outdoor use in coastal areas, rainy climates, or humid worksites. Unlike plain steel ropes that rust quickly, this galvanized option maintains its integrity even after years of exposure to harsh weather.

As a high-quality Galvanized Steel Wire Rope, it retains the inherent strength of premium steel, enabling it to withstand steady loads and occasional impacts without stretching or breaking. Its robust construction ensures a long service life, cutting down on replacement costs and maintenance efforts.

Designed for ease of use, the 9.1MM Zip Line Cable works with standard zip line hardware— including pulleys, anchors, and tensioning tools— eliminating the need for specialized equipment. Its flexibility allows it to adapt to different installation layouts, from straight zip lines to gently curved paths.

The galvanized coating and high-grade steel core mean this rope requires minimal upkeep. It resists dirt buildup and corrosion, so you won’t need frequent oiling or cleaning to keep it in top condition. This makes it a cost-effective choice for both residential and commercial users.

As a Certified Zip Line Cable, it meets global quality benchmarks, ensuring it complies with safety standards for load-bearing applications. This certification gives users peace of mind, knowing the rope has undergone rigorous testing to confirm its reliability.

We prioritize safety and consistency in every Certified 9.1MM Galvanized Steel Wire Rope we produce. Each unit starts with material testing— we select only high-grade steel that meets our strict strength and purity criteria. The galvanization process is closely monitored to ensure an even, thick coating that provides maximum protection. Before shipment, every rope undergoes structural inspections, including checks for strand alignment and coating adhesion, to eliminate defective products. Our manufacturing facility holds ISO 9001 and SGS certifications, ensuring production follows global quality management practices. We stand behind our products with a commitment to delivering only those that meet or exceed customer safety expectations.

Yes, this Certified Zip Line Cable is designed for commercial use. Its high tensile strength and compliance with safety standards make it capable of handling the regular, repeated loads of commercial zip line operations.

Absolutely. We offer customized Galvanized Steel Wire Rope solutions, including cutting to your desired length. Simply share your project requirements, and our team will tailor the rope to fit your needs.

The galvanized coating is built for durability. Minor wear may occur in high-friction areas (like around pulleys), but the coating’s thickness ensures it continues to protect the underlying steel. Periodic inspections of high-wear points will help extend its life.

The Certified Zip Line Cable (9.1MM) is a premium Galvanized Steel Wire Rope engineered for zip line installations, light-duty lifting, and suspended systems that prioritize safety and long-term reliability. Made from high-grade steel, this wire rope adheres to strict industry certifications, ensuring it performs consistently in both indoor recreational setups and outdoor industrial environments. Whether you’re building a backyard zip line or equipping a commercial adventure park, this steel wire rope delivers the stability needed to support regular use without compromising on safety. Its 9.1MM diameter strikes a perfect balance between flexibility and strength, making it suitable for diverse applications where a durable, corrosion-resistant cable is essential.

| Product Name | steel wire rope | |||

| Raw material | quality carbon steel | |||

| Standard | ISO, DIN, ASTM, GB, etc. | |||

| Construction | 8X61+FC 8X61+IWR | |||

| Features | Steel Cables have smooth surface, high corrosion resistant, high fatigue strength, excellent heat resistance and are free from Lateral / longitudinal cracks, pits and marks etc | |||

| Range of products | (Galvanized, Ungalvanized, coated PVC /PE )steel wire rope Hot dip galvanized steel wire rope, etc | |||

| Packing | plastic wheel, solid wood wheel, plywood wheel, coils, bag, etc | |||

The 9.1MM Galvanized Steel Wire Rope boasts a smooth, uniform surface with a bright zinc coating that enhances its visual appeal while forming a protective barrier against environmental damage. Its flexible strand construction allows it to bend easily around pulleys and anchors without kinking— a key feature for zip line systems that require smooth, uninterrupted movement. Unlike ungalvanized alternatives, the rope has no rough edges or uneven spots, ensuring consistent contact with hardware and reducing wear over time. It is supplied in a tangle-free form, with a sleek profile that simplifies handling during installation. The galvanized finish gives the rope a professional look, making it suitable for both functional and aesthetically focused projects.

The galvanized coating on this wire rope acts as a shield against moisture, salt, and corrosive chemicals, making it ideal for outdoor use in coastal areas, rainy climates, or humid worksites. Unlike plain steel ropes that rust quickly, this galvanized option maintains its integrity even after years of exposure to harsh weather.

As a high-quality Galvanized Steel Wire Rope, it retains the inherent strength of premium steel, enabling it to withstand steady loads and occasional impacts without stretching or breaking. Its robust construction ensures a long service life, cutting down on replacement costs and maintenance efforts.

Designed for ease of use, the 9.1MM Zip Line Cable works with standard zip line hardware— including pulleys, anchors, and tensioning tools— eliminating the need for specialized equipment. Its flexibility allows it to adapt to different installation layouts, from straight zip lines to gently curved paths.

The galvanized coating and high-grade steel core mean this rope requires minimal upkeep. It resists dirt buildup and corrosion, so you won’t need frequent oiling or cleaning to keep it in top condition. This makes it a cost-effective choice for both residential and commercial users.

As a Certified Zip Line Cable, it meets global quality benchmarks, ensuring it complies with safety standards for load-bearing applications. This certification gives users peace of mind, knowing the rope has undergone rigorous testing to confirm its reliability.

We prioritize safety and consistency in every Certified 9.1MM Galvanized Steel Wire Rope we produce. Each unit starts with material testing— we select only high-grade steel that meets our strict strength and purity criteria. The galvanization process is closely monitored to ensure an even, thick coating that provides maximum protection. Before shipment, every rope undergoes structural inspections, including checks for strand alignment and coating adhesion, to eliminate defective products. Our manufacturing facility holds ISO 9001 and SGS certifications, ensuring production follows global quality management practices. We stand behind our products with a commitment to delivering only those that meet or exceed customer safety expectations.

Yes, this Certified Zip Line Cable is designed for commercial use. Its high tensile strength and compliance with safety standards make it capable of handling the regular, repeated loads of commercial zip line operations.

Absolutely. We offer customized Galvanized Steel Wire Rope solutions, including cutting to your desired length. Simply share your project requirements, and our team will tailor the rope to fit your needs.

The galvanized coating is built for durability. Minor wear may occur in high-friction areas (like around pulleys), but the coating’s thickness ensures it continues to protect the underlying steel. Periodic inspections of high-wear points will help extend its life.