- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

4VX39S+5FC 4VX48S+5FC

| Availability: | |

|---|---|

| Quantity: | |

The rope’s visual and tactile attributes directly reflect its quality, with design choices tailored to both functionality and application adaptability.

• Galvanized version: Features a hot-dip galvanized coating (thickness 80-120μm) that forms a uniform zinc layer. This coating creates a barrier against moisture, saltwater, and industrial chemicals—critical for outdoor or marine use. The surface has a subtle metallic sheen, with no visible gaps in the zinc layer to prevent localized corrosion.

• Ungalvanized version: Boasts a smooth, clean steel surface (mill-finished) for scenarios where coating flaking is a concern, such as indoor lifting systems or precision machinery. Its matte gray tone ensures easy inspection for wear or deformation.

Each rope consists of 4 symmetrically arranged strands, a design that sets it apart from traditional 6-strand ropes. For the 4VX39S+5FC model, each strand contains 39 high-carbon steel wires twisted in a “S” (right-hand) lay; the 4VX48S+5FC model uses 48 wires per strand for enhanced flexibility. The strands are tightly compacted, with no loose wires—ensuring consistent diameter (ranging from 6mm to 50mm) and a balanced profile that resists kinking.

The rope is wound on heavy-duty wooden or steel reels (diameter 300mm-1200mm) to prevent tangling during storage and transportation. Standard lengths include 100m/reel, 500m/reel, and 1000m/reel, with custom lengths available for large-scale projects. Each reel is labeled with model number, surface type, diameter, and tensile strength for quick identification.

The rope's performance relies on its innovative mechanical structure, which eliminates rotation and boosts load-bearing capacity.

Unlike single-strand or asymmetric multi-strand ropes, the 4-strand design uses counter-balanced twisting: two strands are twisted clockwise, and the other two counterclockwise. This cancels out torque generated when lifting heavy loads (up to 50 tons for large diameters), preventing the rope from spinning or the load from swinging. This mechanism is especially vital for crane operations, where rotation can cause accidents or load damage.

At the rope’s center is a 5FC (5-fiber core)—made of high-strength polyester or polypropylene fibers. The fiber core acts as a buffer: it absorbs shock during sudden lifts, reduces friction between strands, and maintains the rope’s shape under bending (e.g., when passing through pulleys). The “VX” structure (vertical cross-lay) of the strands further enhances stability, ensuring each strand bears equal load and minimizing premature wear.

All steel wires use high-carbon steel (SWRH 82B grade) with a tensile strength of 1960MPa—enough to withstand repeated heavy loads without permanent deformation. The wire surface is polished to reduce abrasion, extending the rope’s service life to 3-5 years (depending on usage). Additionally, the 4-strand design distributes weight evenly, avoiding stress concentrations that lead to wire breakage.

To ensure compatibility and safety, the rope comes with industry-standard accessories and complies with global quality norms.

Each rope set includes:

• Wire rope thimbles: Made of galvanized steel, these protect the rope’s eyelets from wear when connected to shackles or hooks.

• Swivels: Stainless steel swivels (rated for 2000rpm) work with the no-rotating mechanism to further reduce torque in dynamic lifts.

• Lubrication grease: A high-temperature resistant grease (operating range -40°C to 120°C) is included to maintain strand flexibility and prevent rust.

The rope meets international standards, including:

• ISO 17893: For steel wire ropes used in general lifting applications.

• EN 12385-4: Specifies requirements for non-rotating ropes for cranes and hoists.

• ASTM A475: Ensures the galvanized coating’s corrosion resistance meets North American standards. These certifications make the rope suitable for global markets, from Europe to North America.

Every batch includes a test report with data from:

• Tensile strength tests: Conducted via hydraulic testing machines to verify load capacity.

• Corrosion tests: Salt spray tests (48 hours for galvanized versions) to confirm coating durability.

• Twist tests: Measuring rotation under 75% of maximum load to validate the no-rotating function. These reports are provided to customers as proof of quality.

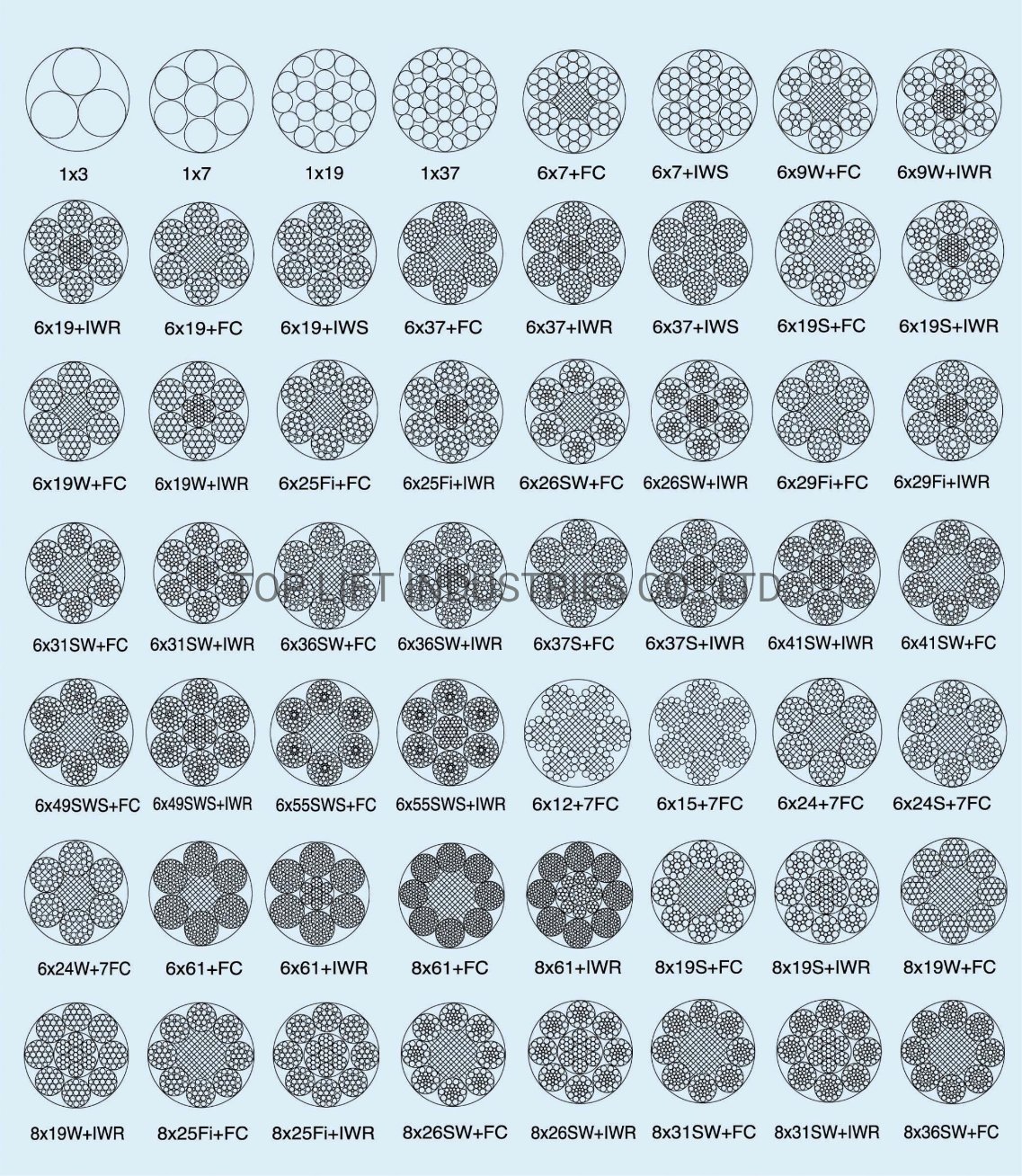

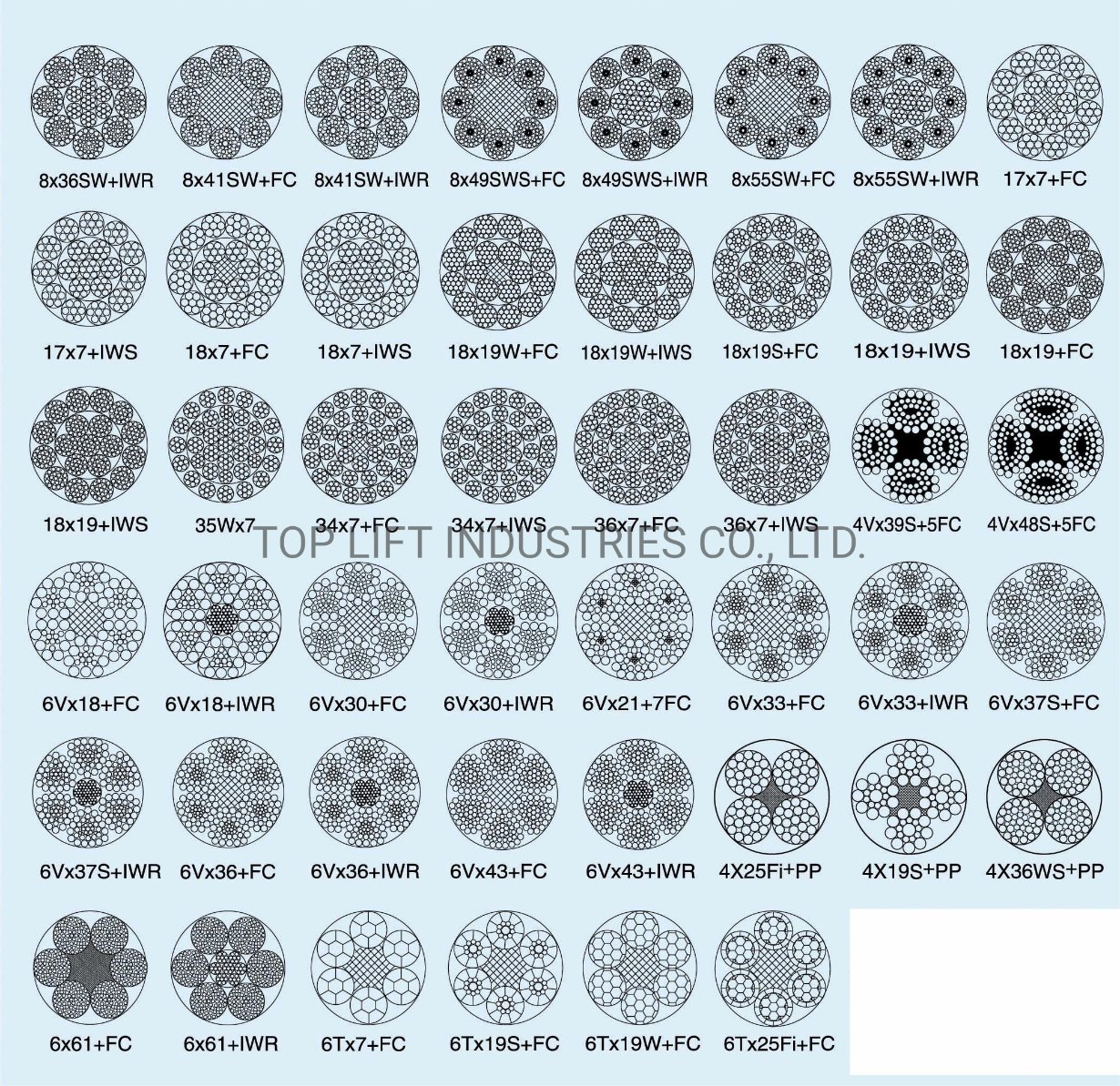

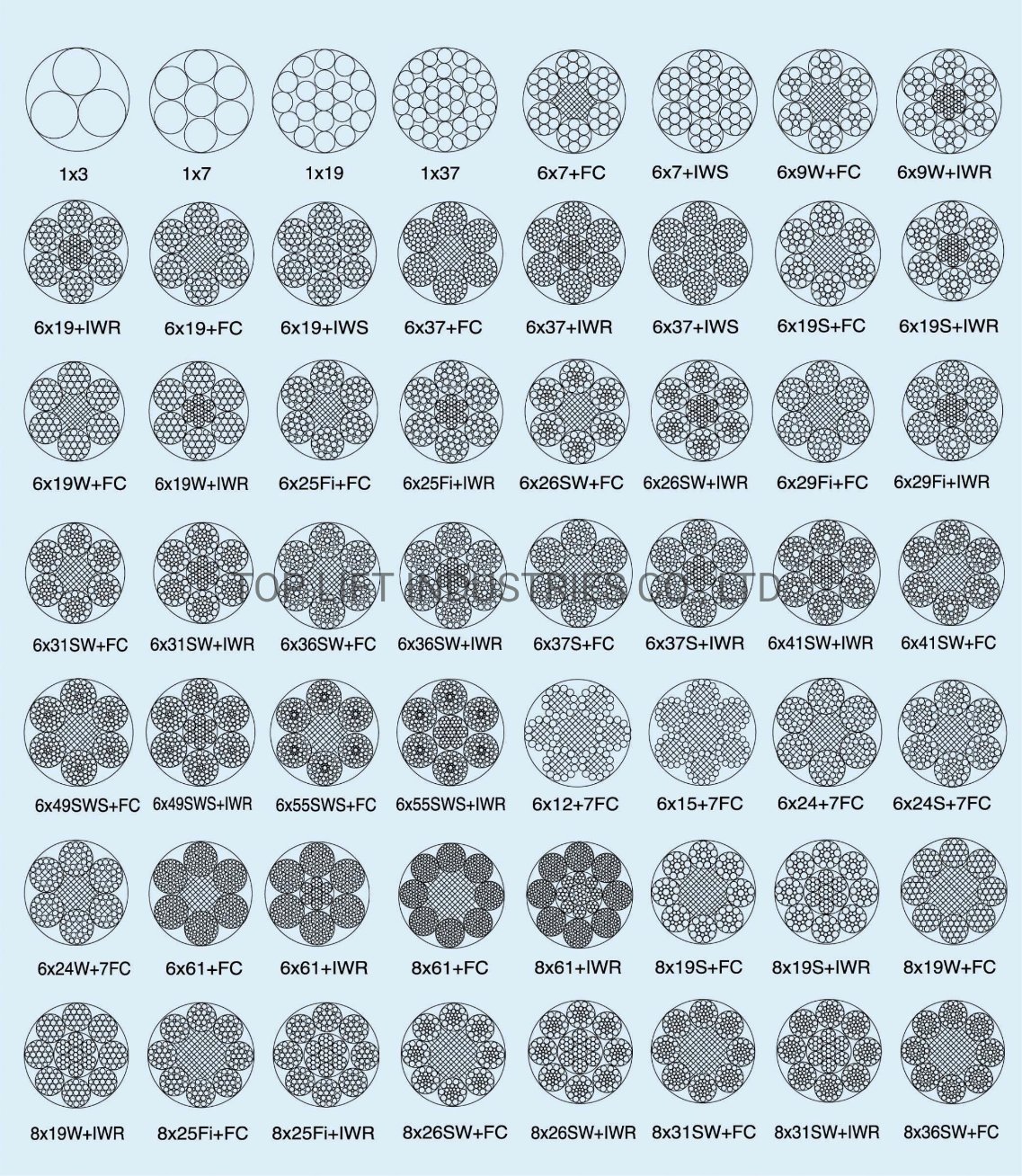

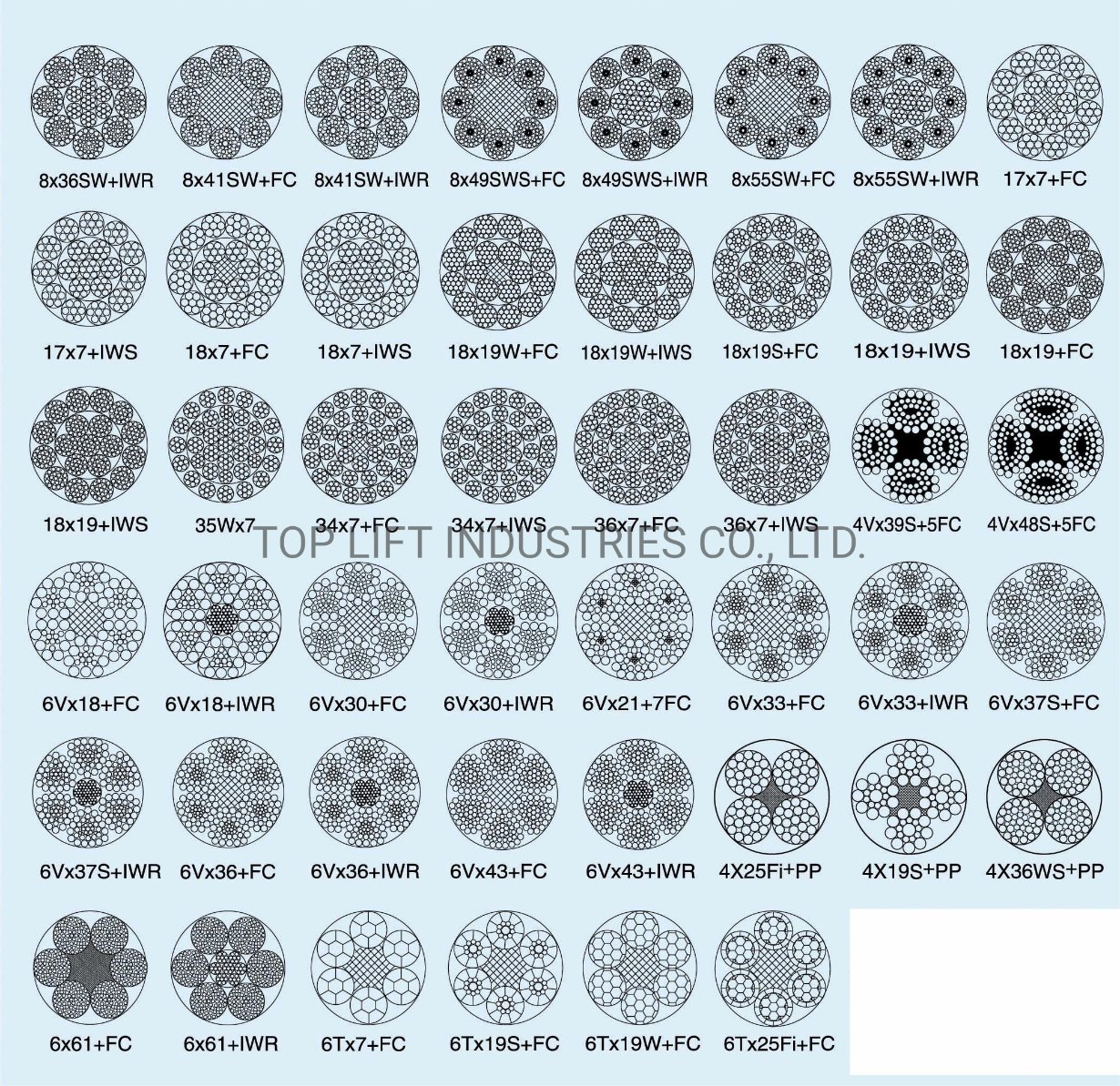

Typical Cross Sections Of Wire Rope&Strand

The rope’s visual and tactile attributes directly reflect its quality, with design choices tailored to both functionality and application adaptability.

• Galvanized version: Features a hot-dip galvanized coating (thickness 80-120μm) that forms a uniform zinc layer. This coating creates a barrier against moisture, saltwater, and industrial chemicals—critical for outdoor or marine use. The surface has a subtle metallic sheen, with no visible gaps in the zinc layer to prevent localized corrosion.

• Ungalvanized version: Boasts a smooth, clean steel surface (mill-finished) for scenarios where coating flaking is a concern, such as indoor lifting systems or precision machinery. Its matte gray tone ensures easy inspection for wear or deformation.

Each rope consists of 4 symmetrically arranged strands, a design that sets it apart from traditional 6-strand ropes. For the 4VX39S+5FC model, each strand contains 39 high-carbon steel wires twisted in a “S” (right-hand) lay; the 4VX48S+5FC model uses 48 wires per strand for enhanced flexibility. The strands are tightly compacted, with no loose wires—ensuring consistent diameter (ranging from 6mm to 50mm) and a balanced profile that resists kinking.

The rope is wound on heavy-duty wooden or steel reels (diameter 300mm-1200mm) to prevent tangling during storage and transportation. Standard lengths include 100m/reel, 500m/reel, and 1000m/reel, with custom lengths available for large-scale projects. Each reel is labeled with model number, surface type, diameter, and tensile strength for quick identification.

The rope's performance relies on its innovative mechanical structure, which eliminates rotation and boosts load-bearing capacity.

Unlike single-strand or asymmetric multi-strand ropes, the 4-strand design uses counter-balanced twisting: two strands are twisted clockwise, and the other two counterclockwise. This cancels out torque generated when lifting heavy loads (up to 50 tons for large diameters), preventing the rope from spinning or the load from swinging. This mechanism is especially vital for crane operations, where rotation can cause accidents or load damage.

At the rope’s center is a 5FC (5-fiber core)—made of high-strength polyester or polypropylene fibers. The fiber core acts as a buffer: it absorbs shock during sudden lifts, reduces friction between strands, and maintains the rope’s shape under bending (e.g., when passing through pulleys). The “VX” structure (vertical cross-lay) of the strands further enhances stability, ensuring each strand bears equal load and minimizing premature wear.

All steel wires use high-carbon steel (SWRH 82B grade) with a tensile strength of 1960MPa—enough to withstand repeated heavy loads without permanent deformation. The wire surface is polished to reduce abrasion, extending the rope’s service life to 3-5 years (depending on usage). Additionally, the 4-strand design distributes weight evenly, avoiding stress concentrations that lead to wire breakage.

To ensure compatibility and safety, the rope comes with industry-standard accessories and complies with global quality norms.

Each rope set includes:

• Wire rope thimbles: Made of galvanized steel, these protect the rope’s eyelets from wear when connected to shackles or hooks.

• Swivels: Stainless steel swivels (rated for 2000rpm) work with the no-rotating mechanism to further reduce torque in dynamic lifts.

• Lubrication grease: A high-temperature resistant grease (operating range -40°C to 120°C) is included to maintain strand flexibility and prevent rust.

The rope meets international standards, including:

• ISO 17893: For steel wire ropes used in general lifting applications.

• EN 12385-4: Specifies requirements for non-rotating ropes for cranes and hoists.

• ASTM A475: Ensures the galvanized coating’s corrosion resistance meets North American standards. These certifications make the rope suitable for global markets, from Europe to North America.

Every batch includes a test report with data from:

• Tensile strength tests: Conducted via hydraulic testing machines to verify load capacity.

• Corrosion tests: Salt spray tests (48 hours for galvanized versions) to confirm coating durability.

• Twist tests: Measuring rotation under 75% of maximum load to validate the no-rotating function. These reports are provided to customers as proof of quality.

Typical Cross Sections Of Wire Rope&Strand