- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

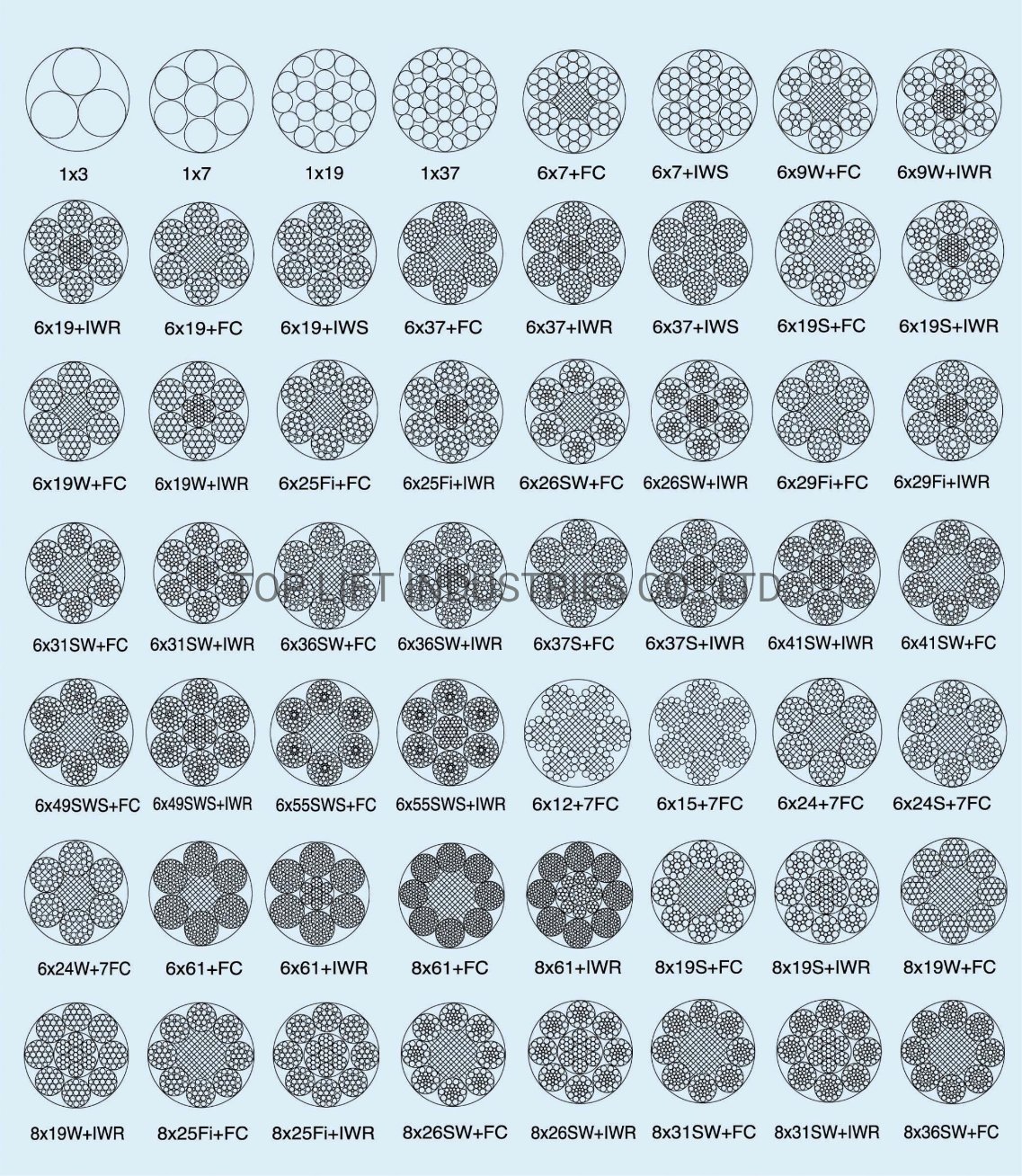

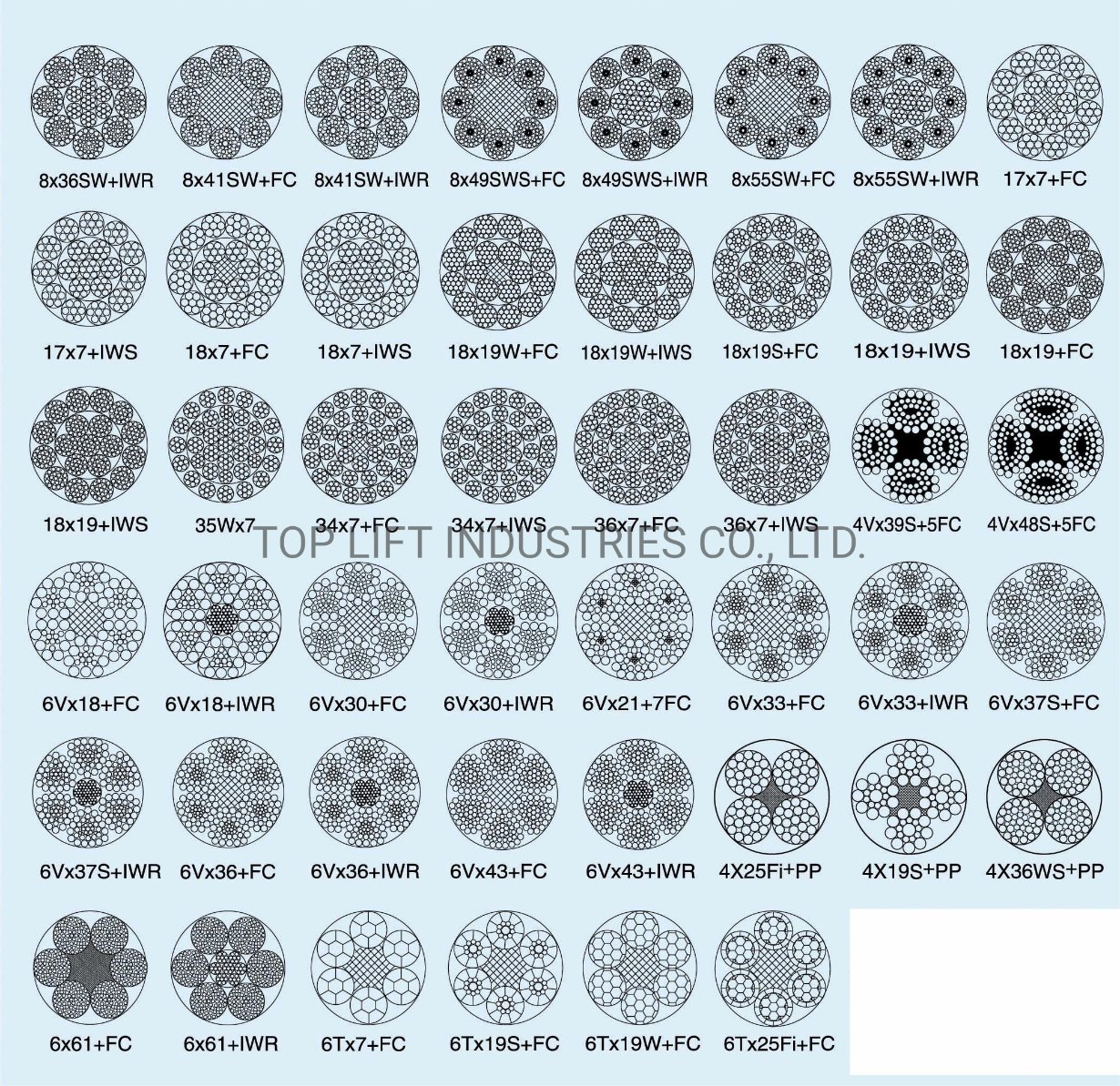

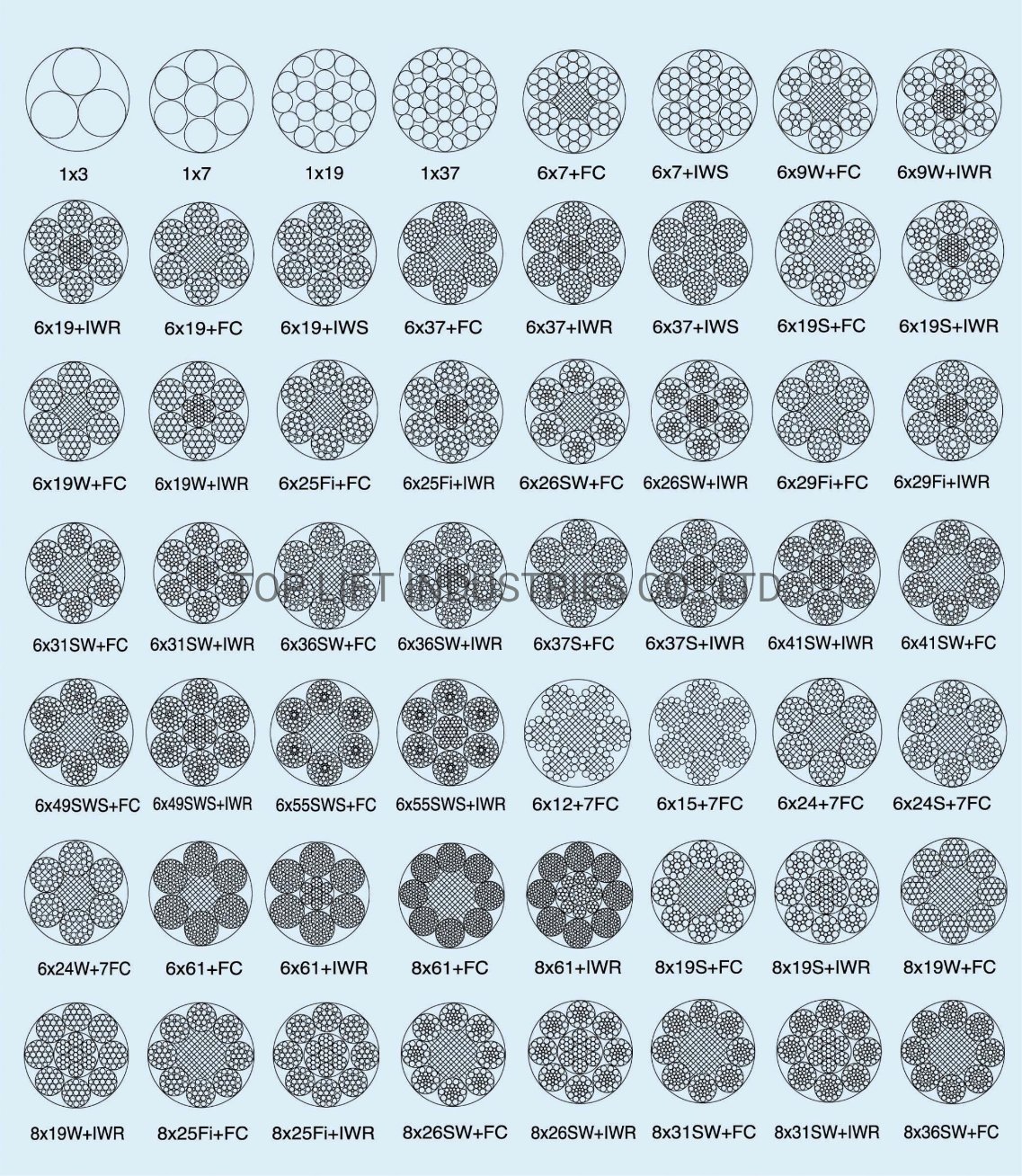

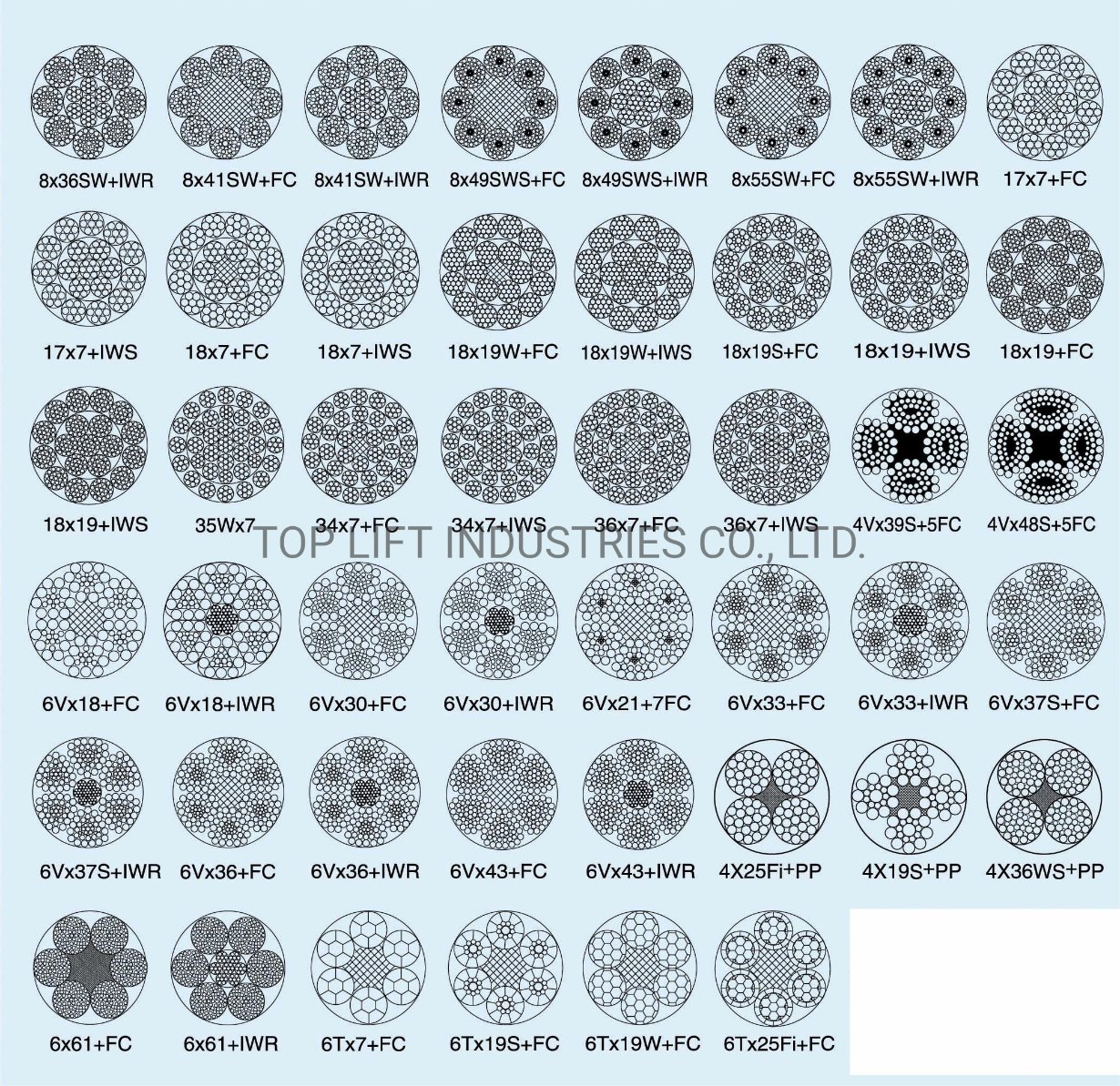

6X19S+FC 6X19S+WSC 6X19W+FC 6X19W+IWRC

| Availability: | |

|---|---|

| Quantity: | |

The TOPLIFT High-Quality Steel Wire Rope is a specialized spare part designed exclusively for construction elevators, integrating reliability and durability to meet the rigorous demands of construction sites. Crafted with premium low-carbon wire, this steel wire rope serves as a critical component that ensures the safe and smooth operation of construction elevators, whether in high-rise building projects or large-scale infrastructure developments. It is engineered to withstand the harsh conditions of construction environments, providing stable support for elevator operation and contributing to the overall efficiency of construction workflows. As an essential construction elevator spare part, it has gained recognition for its consistent performance and ability to adapt to various operational requirements.

Material | Carbon Steel |

Diameter Range | 6mm to 56mm |

Lay | Right interaction twist, Left interaction twist, Right direction twist, Left direction twist |

Tensile Strength | 1570/1670/ 1770/ 1870/1960/2160KN |

Surface Treatment | Ungalvanized, Electro Galvanized, Hot Dip Galvanized, PVC Coated |

Nom.Diam. | Nominal Tensile Strength of Rope Approx.weight | |||||||||||||

1570 1670 | 1770 | 1870 | 1960 | 2160 | kg/100m | |||||||||

KN KN | KN | KN | KN | KN | ||||||||||

FC | IWRC | FC | IWRC | FC | IWRC | FC | IWRC | FC | IWRC | FC | IWRC | FC | IWRC | |

6 | 18.7 | 20.1 | 19.8 | 21.4 | 21.0 | 22.7 | 22.2 | 24.0 | 23.3 | 25.1 | 25.7 | 27.7 | 13.3 | 14.6 |

7 | 25.4 | 27.4 | 27.0 | 29.1 | 28.6 | 30.9 | 30.2 | 32.6 | 31.7 | 34.2 | 34.9 | 37.7 | 18.1 | 19.9 |

8 | 33.2 | 35.8 | 35.3 | 38.0 | 37.4 | 40.3 | 39.5 | 42.6 | 41.4 | 44.6 | 45.6 | 492 | 23.6 | 25.9 |

9 | 42.0 | 45.1 | 44.6 | 48.2 | 47.3 | 51.0 | 50.0 | 53.9 | 52.4 | 56.5 | 57.7 | 62.3 | 29.9 | 32.8 |

10 | 51.8 | 55.9 | 55.1 | 59.5 | 58.4 | 63.0 | 61.7 | 66.6 | 64.7 | 69.8 | 71.3 | 76.9 | 36.9 | 40.6 |

11 | 62.7 | 67.6 | 66.7 | 71.9 | 70.7 | 76.2 | 74.7 | 80.6 | 78.3 | 84.4 | 862 | 93.0 | 44.6 | 49.1 |

12 | 74.6 | 80.5 | 79.4 | 85.6 | 84.1 | 90.7 | 88.9 | 95.9 | 93.1 | 100 | 103 | 111 | 53.1 | 58.4 |

13 | 87.6 | 94.5 | 93.1 | 100 | 98.7 | 106 | 104 | 113 | 109 | 118 | 120 | 130 | 62.3 | 68.5 |

14 | 102 | 110 | 108 | 117 | 114 | 124 | 121 | 130 | 127 | 137 | 140 | 151 | 72.2 | 79.5 |

16 | 133 | 143 | 141 | 152 | 150 | 161 | 158 | 170 | 166 | 179 | 182 | 197 | 94.4 | 104 |

18 | 168 | 181 | 179 | 193 | 189 | 204 | 200 | 216 | 210 | 226 | 231 | 249 | 119 | 131 |

20 | 207 | 224 | 220 | 238 | 234 | 252 | 247 | 266 | 259 | 279 | 285 | 308 | 147 | 162 |

22 | 251 | 271 | 267 | 288 | 283 | 305 | 299 | 322 | 318 | 338 | 345 | 372 | 178 | 196 |

24 | 298 | 322 | 317 | 342 | 336 | 363 | 355 | 383 | 373 | 402 | 411 | 443 | 212 | 234 |

26 | 350 | 378 | 373 | 402 | 395 | 426 | 417 | 450 | 437 | 472 | 482 | 520 | 249 | 274 |

28 | 406 | 438 | 432 | 466 | 458 | 494 | 484 | 522 | 507 | 547 | 559 | 603 | 289 | 318 |

30 | 466 | 503 | 496 | 535 | 526 | 567 | 555 | 599 | 582 | 628 | 642 | 692 | 332 | 365 |

32 | 531 | 572 | 564 | 609 | 598 | 645 | 632 | 682 | 662 | 715 | 730 | 787 | 377 | 415 |

34 | 599 | 646 | 637 | 687 | 675 | 728 | 713 | 770 | 748 | 807 | 824 | 889 | 426 | 469 |

36 | 671 | 724 | 714 | 770 | 757 | 817 | 800 | 863 | 838 | 904 | 924 | 997 | 478 | 525 |

38 | 748 | 807 | 796 | 858 | 843 | 910 | 891 | 961 | 934 | 1010 | 1030 | 1110 | 532 | 585 |

40 | 829 | 894 | 882 | 951 | 935 | 1010 | 987 | 1070 | 1030 | 1120 | 1140 | 1230 | 590 | 649 |

42 | 914 | 986 | 972 | 1050 | 1030 | 1110 | 1090 | 1170 | 1140 | 1230 | 1260 | 1360 | 651 | 716 |

44 | 1000 | 1080 | 1070 | 1150 | 1130 | 1220 | 1190 | 1290 | 1280 | 1350 | 1380 | 1490 | 714 | 786 |

46 | 1100 | 1188 | 1170 | 1260 | 1230 | 1330 | 1310 | 1410 | 1370 | 1480 | 1510 | 1630 | 781 | 859 |

48 | 1190 | 1290 | 1270 | 1370 | 1340 | 1450 | 1420 | 1530 | 1490 | 1630 | 1640 | 1770 | 850 | 935 |

50 | 1290 | 1400 | 1380 | 1490 | 1460 | 1570 | 1540 | 1660 | 1620 | 1740 | 1780 | 1920 | 922 | 1015 |

52 | 1406 | 1510 | 1490 | 1610 | 1580 | 1700 | 1670 | 1800 | 1750 | 1890 | 1930 | 2080 | 998 | 1098 |

54 | 1510 | 1630 | 1610 | 1730 | 1700 | 1840 | 1800 | 1940 | 1890 | 2030 | 2080 | 2240 | 1076 | 1184 |

56 | 2930 | 3160 | 3120 | 3360 | 3300 | 3560 | 3490 | 3760 | 3660 | 3950 | 4030 | 4350 | 1157 | 1273 |

The low-carbon steel wire rope features a sleek and uniform structure, with tightly twisted strands that form a robust and cohesive body. The surface of the wire rope is treated with a protective coating, giving it a smooth finish that not only enhances its aesthetic appeal but also provides resistance against corrosion and wear. Each strand is precisely arranged to ensure symmetry and balance, contributing to the rope’s overall strength and stability. The ends of the wire rope are equipped with high-quality fittings that are seamlessly integrated, ensuring secure connections and easy installation. The neutral color of the steel wire rope allows it to blend naturally with the mechanical components of construction elevators, maintaining a professional and industrial look that aligns with construction site aesthetics.

Made from high-grade low-carbon steel, the TOPLIFT steel wire rope boasts exceptional tensile strength, enabling it to bear heavy loads without deformation or breakage. The low-carbon material enhances the rope’s flexibility while maintaining its structural integrity, ensuring long-term reliable use even under frequent and intense operational stress. This durability minimizes the need for frequent replacements, reducing downtime and maintenance costs for construction projects.

The protective coating on the surface of the construction elevator wire rope effectively shields it from moisture, dust, and other corrosive elements commonly found in construction environments. This resistance to corrosion and wear extends the rope’s service life, ensuring consistent performance in both indoor and outdoor construction settings. Whether exposed to rain, humidity, or abrasive materials, the rope remains intact and functional, providing peace of mind to construction teams.

Designed as a dedicated spare steel wire rope for construction elevators, it offers perfect compatibility with a wide range of elevator models and brands. The precise dimensions and specifications of the rope ensure a seamless fit, eliminating the need for modifications or adjustments during installation. This compatibility simplifies the replacement process, allowing construction teams to quickly and efficiently install the rope and resume elevator operation.

The high-quality steel wire rope is engineered with strict quality control measures to ensure stable and reliable performance in all operational scenarios. It maintains consistent tension and flexibility, enabling smooth elevator movement and precise control. Even under varying load conditions and frequent use, the rope does not experience sudden failures or performance fluctuations, ensuring the safety of personnel and equipment in construction sites.

We source only premium low-carbon steel from trusted suppliers, conducting thorough inspections to ensure the material meets our strict quality standards. Each batch of steel undergoes chemical and mechanical testing to verify its tensile strength, flexibility, and corrosion resistance, ensuring that only the highest-quality materials are used in the production of the steel wire rope.

The production of the TOPLIFT construction elevator spare part follows a sophisticated and precise manufacturing process. From wire drawing and stranding to twisting and coating, each step is monitored by experienced technicians using advanced equipment. This meticulous manufacturing approach ensures that every low-carbon wire steel rope meets the exact specifications and performance requirements, guaranteeing uniformity and consistency across all products.

Before leaving the factory, each high-quality steel wire rope undergoes a series of comprehensive tests, including tensile strength testing, fatigue testing, and corrosion resistance testing. These tests are designed to simulate real-world operating conditions and ensure that the rope can withstand the demands of construction elevator operation. Only products that pass all quality tests are approved for shipment, providing customers with a reliable and high-performance product.

The TOPLIFT steel wire rope is designed to be compatible with most standard construction elevator models and brands. However, it is recommended to check the specifications of your elevator before purchase to ensure a perfect fit. Our customer service team is also available to assist you in verifying compatibility based on your elevator’s make and model.

To ensure safety and performance, it is advisable to inspect the construction elevator spare steel wire rope regularly, ideally before each use or at least once a week. During inspection, check for signs of wear, corrosion, fraying, or deformation. If any abnormalities are detected, replace the rope immediately to avoid potential safety hazards.

Yes, the low-carbon steel wire rope is specifically designed to withstand outdoor conditions. Its protective coating provides excellent resistance against corrosion and wear caused by exposure to rain, humidity, and other environmental factors. It is fully suitable for use in both indoor and outdoor construction projects, delivering consistent performance regardless of the environment.

The installation of the high-quality steel wire rope is straightforward, thanks to its perfect compatibility and user-friendly design. First, ensure that the elevator is powered off and secured to prevent accidental movement. Then, remove the old rope and carefully attach the new rope using the provided fittings, following the elevator manufacturer’s guidelines. It is recommended to have the installation performed by trained professionals to ensure proper installation and maximum safety.

The TOPLIFT High-Quality Steel Wire Rope is a specialized spare part designed exclusively for construction elevators, integrating reliability and durability to meet the rigorous demands of construction sites. Crafted with premium low-carbon wire, this steel wire rope serves as a critical component that ensures the safe and smooth operation of construction elevators, whether in high-rise building projects or large-scale infrastructure developments. It is engineered to withstand the harsh conditions of construction environments, providing stable support for elevator operation and contributing to the overall efficiency of construction workflows. As an essential construction elevator spare part, it has gained recognition for its consistent performance and ability to adapt to various operational requirements.

Material | Carbon Steel |

Diameter Range | 6mm to 56mm |

Lay | Right interaction twist, Left interaction twist, Right direction twist, Left direction twist |

Tensile Strength | 1570/1670/ 1770/ 1870/1960/2160KN |

Surface Treatment | Ungalvanized, Electro Galvanized, Hot Dip Galvanized, PVC Coated |

Nom.Diam. | Nominal Tensile Strength of Rope Approx.weight | |||||||||||||

1570 1670 | 1770 | 1870 | 1960 | 2160 | kg/100m | |||||||||

KN KN | KN | KN | KN | KN | ||||||||||

FC | IWRC | FC | IWRC | FC | IWRC | FC | IWRC | FC | IWRC | FC | IWRC | FC | IWRC | |

6 | 18.7 | 20.1 | 19.8 | 21.4 | 21.0 | 22.7 | 22.2 | 24.0 | 23.3 | 25.1 | 25.7 | 27.7 | 13.3 | 14.6 |

7 | 25.4 | 27.4 | 27.0 | 29.1 | 28.6 | 30.9 | 30.2 | 32.6 | 31.7 | 34.2 | 34.9 | 37.7 | 18.1 | 19.9 |

8 | 33.2 | 35.8 | 35.3 | 38.0 | 37.4 | 40.3 | 39.5 | 42.6 | 41.4 | 44.6 | 45.6 | 492 | 23.6 | 25.9 |

9 | 42.0 | 45.1 | 44.6 | 48.2 | 47.3 | 51.0 | 50.0 | 53.9 | 52.4 | 56.5 | 57.7 | 62.3 | 29.9 | 32.8 |

10 | 51.8 | 55.9 | 55.1 | 59.5 | 58.4 | 63.0 | 61.7 | 66.6 | 64.7 | 69.8 | 71.3 | 76.9 | 36.9 | 40.6 |

11 | 62.7 | 67.6 | 66.7 | 71.9 | 70.7 | 76.2 | 74.7 | 80.6 | 78.3 | 84.4 | 862 | 93.0 | 44.6 | 49.1 |

12 | 74.6 | 80.5 | 79.4 | 85.6 | 84.1 | 90.7 | 88.9 | 95.9 | 93.1 | 100 | 103 | 111 | 53.1 | 58.4 |

13 | 87.6 | 94.5 | 93.1 | 100 | 98.7 | 106 | 104 | 113 | 109 | 118 | 120 | 130 | 62.3 | 68.5 |

14 | 102 | 110 | 108 | 117 | 114 | 124 | 121 | 130 | 127 | 137 | 140 | 151 | 72.2 | 79.5 |

16 | 133 | 143 | 141 | 152 | 150 | 161 | 158 | 170 | 166 | 179 | 182 | 197 | 94.4 | 104 |

18 | 168 | 181 | 179 | 193 | 189 | 204 | 200 | 216 | 210 | 226 | 231 | 249 | 119 | 131 |

20 | 207 | 224 | 220 | 238 | 234 | 252 | 247 | 266 | 259 | 279 | 285 | 308 | 147 | 162 |

22 | 251 | 271 | 267 | 288 | 283 | 305 | 299 | 322 | 318 | 338 | 345 | 372 | 178 | 196 |

24 | 298 | 322 | 317 | 342 | 336 | 363 | 355 | 383 | 373 | 402 | 411 | 443 | 212 | 234 |

26 | 350 | 378 | 373 | 402 | 395 | 426 | 417 | 450 | 437 | 472 | 482 | 520 | 249 | 274 |

28 | 406 | 438 | 432 | 466 | 458 | 494 | 484 | 522 | 507 | 547 | 559 | 603 | 289 | 318 |

30 | 466 | 503 | 496 | 535 | 526 | 567 | 555 | 599 | 582 | 628 | 642 | 692 | 332 | 365 |

32 | 531 | 572 | 564 | 609 | 598 | 645 | 632 | 682 | 662 | 715 | 730 | 787 | 377 | 415 |

34 | 599 | 646 | 637 | 687 | 675 | 728 | 713 | 770 | 748 | 807 | 824 | 889 | 426 | 469 |

36 | 671 | 724 | 714 | 770 | 757 | 817 | 800 | 863 | 838 | 904 | 924 | 997 | 478 | 525 |

38 | 748 | 807 | 796 | 858 | 843 | 910 | 891 | 961 | 934 | 1010 | 1030 | 1110 | 532 | 585 |

40 | 829 | 894 | 882 | 951 | 935 | 1010 | 987 | 1070 | 1030 | 1120 | 1140 | 1230 | 590 | 649 |

42 | 914 | 986 | 972 | 1050 | 1030 | 1110 | 1090 | 1170 | 1140 | 1230 | 1260 | 1360 | 651 | 716 |

44 | 1000 | 1080 | 1070 | 1150 | 1130 | 1220 | 1190 | 1290 | 1280 | 1350 | 1380 | 1490 | 714 | 786 |

46 | 1100 | 1188 | 1170 | 1260 | 1230 | 1330 | 1310 | 1410 | 1370 | 1480 | 1510 | 1630 | 781 | 859 |

48 | 1190 | 1290 | 1270 | 1370 | 1340 | 1450 | 1420 | 1530 | 1490 | 1630 | 1640 | 1770 | 850 | 935 |

50 | 1290 | 1400 | 1380 | 1490 | 1460 | 1570 | 1540 | 1660 | 1620 | 1740 | 1780 | 1920 | 922 | 1015 |

52 | 1406 | 1510 | 1490 | 1610 | 1580 | 1700 | 1670 | 1800 | 1750 | 1890 | 1930 | 2080 | 998 | 1098 |

54 | 1510 | 1630 | 1610 | 1730 | 1700 | 1840 | 1800 | 1940 | 1890 | 2030 | 2080 | 2240 | 1076 | 1184 |

56 | 2930 | 3160 | 3120 | 3360 | 3300 | 3560 | 3490 | 3760 | 3660 | 3950 | 4030 | 4350 | 1157 | 1273 |

The low-carbon steel wire rope features a sleek and uniform structure, with tightly twisted strands that form a robust and cohesive body. The surface of the wire rope is treated with a protective coating, giving it a smooth finish that not only enhances its aesthetic appeal but also provides resistance against corrosion and wear. Each strand is precisely arranged to ensure symmetry and balance, contributing to the rope’s overall strength and stability. The ends of the wire rope are equipped with high-quality fittings that are seamlessly integrated, ensuring secure connections and easy installation. The neutral color of the steel wire rope allows it to blend naturally with the mechanical components of construction elevators, maintaining a professional and industrial look that aligns with construction site aesthetics.

Made from high-grade low-carbon steel, the TOPLIFT steel wire rope boasts exceptional tensile strength, enabling it to bear heavy loads without deformation or breakage. The low-carbon material enhances the rope’s flexibility while maintaining its structural integrity, ensuring long-term reliable use even under frequent and intense operational stress. This durability minimizes the need for frequent replacements, reducing downtime and maintenance costs for construction projects.

The protective coating on the surface of the construction elevator wire rope effectively shields it from moisture, dust, and other corrosive elements commonly found in construction environments. This resistance to corrosion and wear extends the rope’s service life, ensuring consistent performance in both indoor and outdoor construction settings. Whether exposed to rain, humidity, or abrasive materials, the rope remains intact and functional, providing peace of mind to construction teams.

Designed as a dedicated spare steel wire rope for construction elevators, it offers perfect compatibility with a wide range of elevator models and brands. The precise dimensions and specifications of the rope ensure a seamless fit, eliminating the need for modifications or adjustments during installation. This compatibility simplifies the replacement process, allowing construction teams to quickly and efficiently install the rope and resume elevator operation.

The high-quality steel wire rope is engineered with strict quality control measures to ensure stable and reliable performance in all operational scenarios. It maintains consistent tension and flexibility, enabling smooth elevator movement and precise control. Even under varying load conditions and frequent use, the rope does not experience sudden failures or performance fluctuations, ensuring the safety of personnel and equipment in construction sites.

We source only premium low-carbon steel from trusted suppliers, conducting thorough inspections to ensure the material meets our strict quality standards. Each batch of steel undergoes chemical and mechanical testing to verify its tensile strength, flexibility, and corrosion resistance, ensuring that only the highest-quality materials are used in the production of the steel wire rope.

The production of the TOPLIFT construction elevator spare part follows a sophisticated and precise manufacturing process. From wire drawing and stranding to twisting and coating, each step is monitored by experienced technicians using advanced equipment. This meticulous manufacturing approach ensures that every low-carbon wire steel rope meets the exact specifications and performance requirements, guaranteeing uniformity and consistency across all products.

Before leaving the factory, each high-quality steel wire rope undergoes a series of comprehensive tests, including tensile strength testing, fatigue testing, and corrosion resistance testing. These tests are designed to simulate real-world operating conditions and ensure that the rope can withstand the demands of construction elevator operation. Only products that pass all quality tests are approved for shipment, providing customers with a reliable and high-performance product.

The TOPLIFT steel wire rope is designed to be compatible with most standard construction elevator models and brands. However, it is recommended to check the specifications of your elevator before purchase to ensure a perfect fit. Our customer service team is also available to assist you in verifying compatibility based on your elevator’s make and model.

To ensure safety and performance, it is advisable to inspect the construction elevator spare steel wire rope regularly, ideally before each use or at least once a week. During inspection, check for signs of wear, corrosion, fraying, or deformation. If any abnormalities are detected, replace the rope immediately to avoid potential safety hazards.

Yes, the low-carbon steel wire rope is specifically designed to withstand outdoor conditions. Its protective coating provides excellent resistance against corrosion and wear caused by exposure to rain, humidity, and other environmental factors. It is fully suitable for use in both indoor and outdoor construction projects, delivering consistent performance regardless of the environment.

The installation of the high-quality steel wire rope is straightforward, thanks to its perfect compatibility and user-friendly design. First, ensure that the elevator is powered off and secured to prevent accidental movement. Then, remove the old rope and carefully attach the new rope using the provided fittings, following the elevator manufacturer’s guidelines. It is recommended to have the installation performed by trained professionals to ensure proper installation and maximum safety.