- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

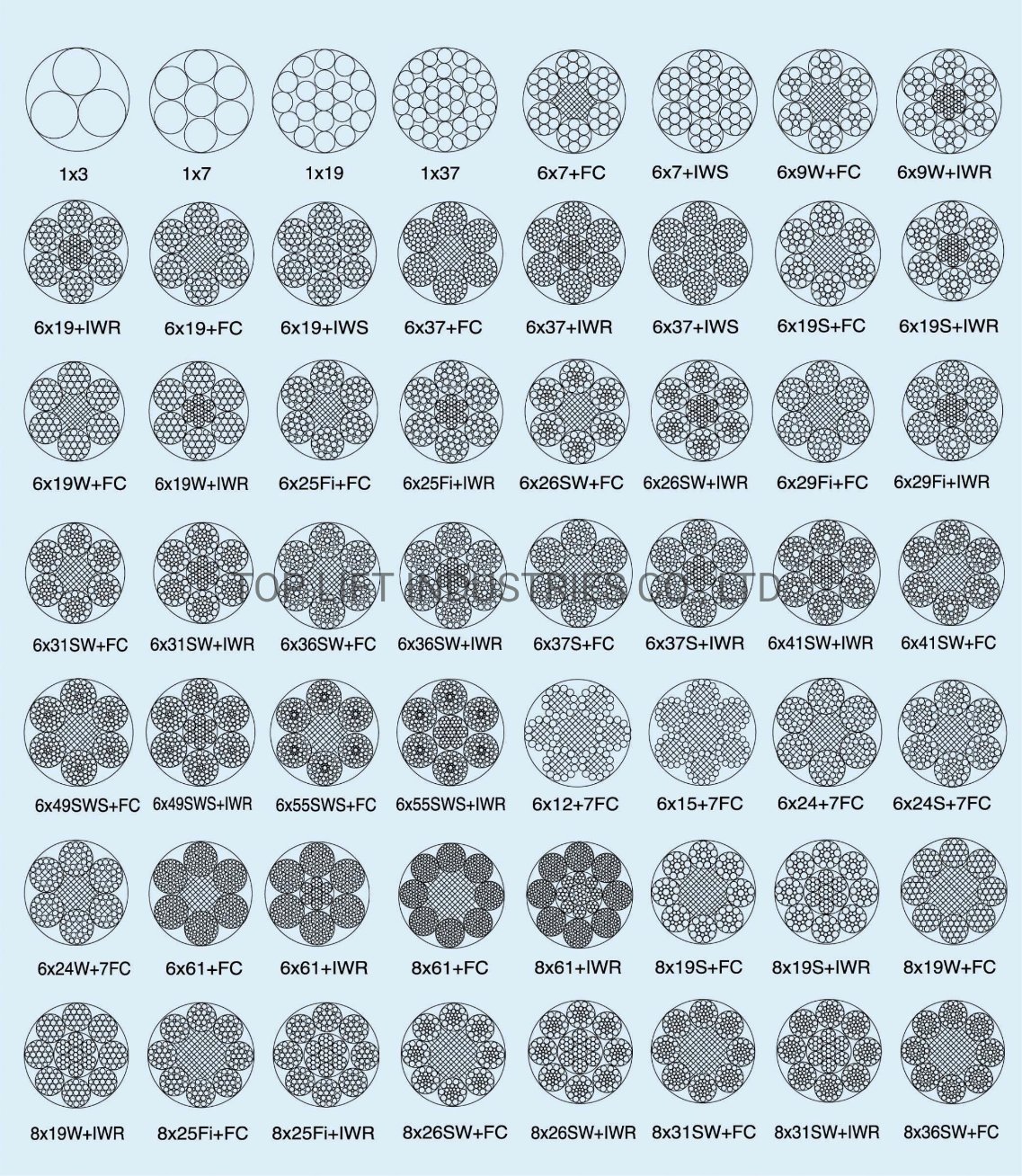

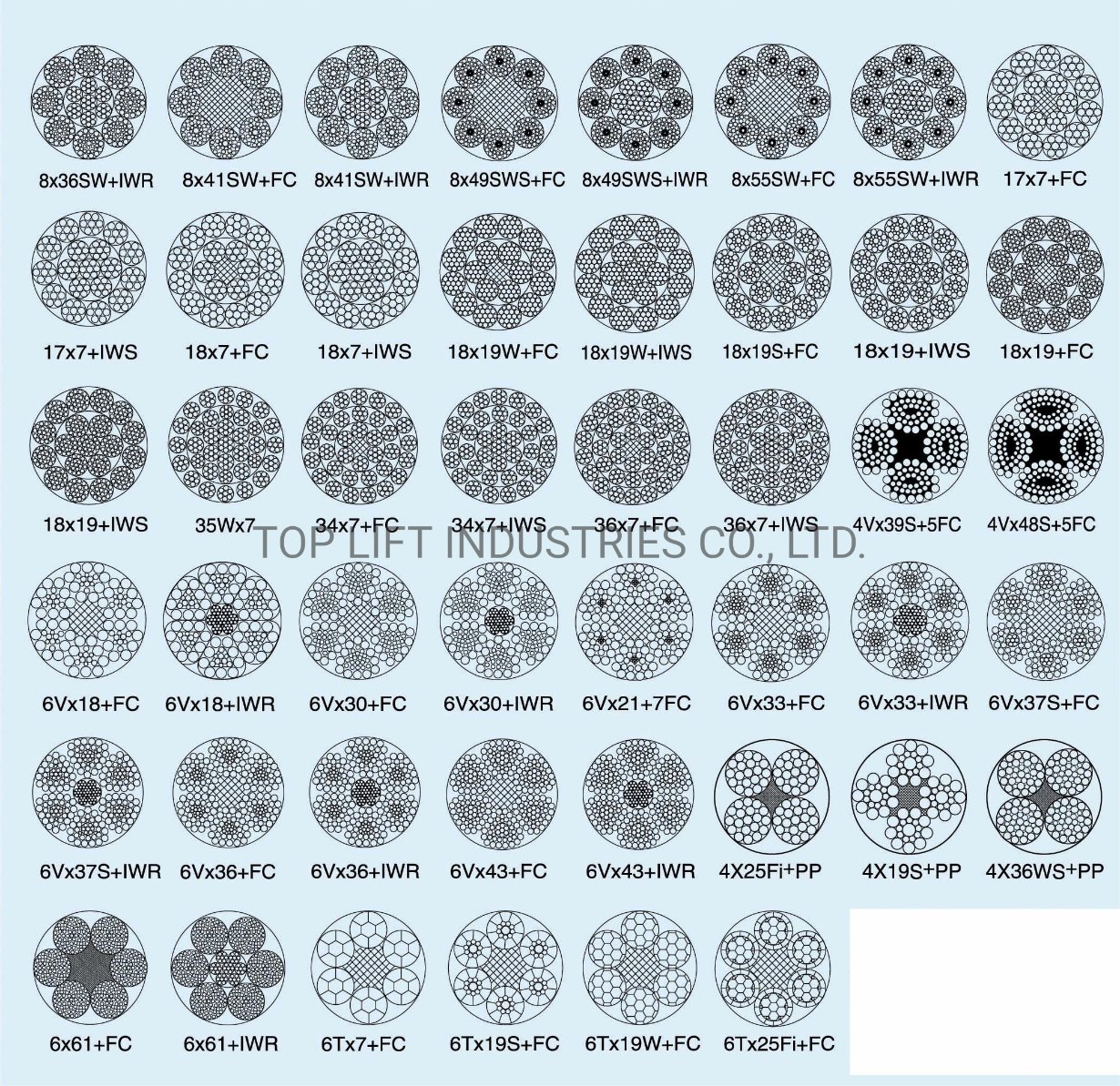

6X25FI+FC 6X25FIIWR 6X26SW+FC 6X26SW+IWR 6X29FI+FC 6X31SW+FC 6X36SW+FC 6X36SW+IWR 6X37S+FC 6X37SW+IWR 6X41SW+FC 6X49SWS+FC 6X55SWS+FC 6X55SWS+IWR

| Availability: | |

|---|---|

| Quantity: | |

Galvanized & Ungalvanized Line Contact Steel Wire Rope is a high-performance lifting and transmission solution engineered for industrial durability and precision. Unlike ordinary wire ropes, its unique line contact structure ensures even load distribution, making it a top choice for heavy-duty operations where stability and longevity matter. Available in both galvanized (zinc-coated for corrosion resistance) and ungalvanized (pure steel for maximum strength) variants, this rope caters to diverse environmental and functional needs. It complies with international standards such as ISO and DIN, ensuring compatibility with global industrial equipment and meeting the strict requirements of professional buyers seeking reliable line contact steel wire rope for critical applications.

Dual-Coating Options: Choose between galvanized steel wire rope (zinc coating prevents rust in moist/harsh environments) and ungalvanized steel wire rope (uncoated pure steel delivers 15% higher tensile strength than galvanized alternatives).

Line Contact Structure: The specialized line contact design minimizes friction between strands, reducing wear and extending the rope’s service life by up to 30% compared to traditional point-contact ropes.

High Tensile Strength: Ranges from 1800MPa to 2200MPa, enabling safe lifting of heavy loads (5T to 50T) in construction and mining scenarios.

Flexible Operation: Maintains excellent flexibility even under dynamic loads, ensuring smooth winding and unwinding on winches and cranes without kinking.

Corrosion Resistance (Galvanized Variant): Hot-dip galvanization provides a thick, uniform zinc layer, making it suitable for outdoor, marine, or coastal applications where moisture is a concern.

Cost-Effective (Ungalvanized Variant): 20% lower cost than galvanized options, ideal for indoor or low-moisture environments where corrosion risk is minimal.

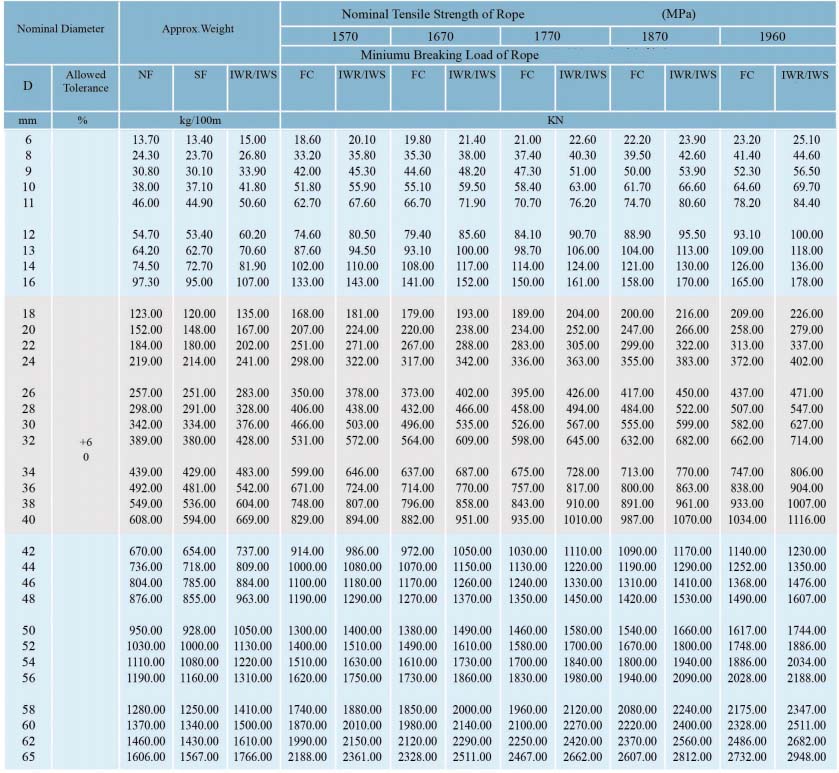

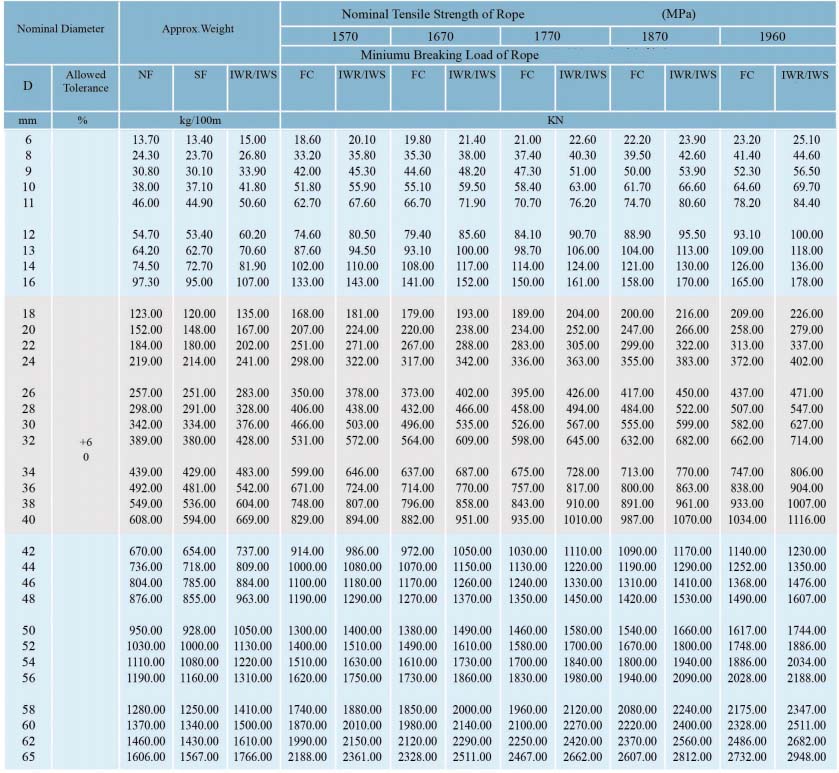

Specification | Galvanized Variant | Ungalvanized Variant |

Construction | 6×19W+FC, 6×36WS+IWRC | 6×19W+FC, 6×36WS+IWRC |

Diameter Range | 8mm - 40mm | 8mm - 40mm |

Tensile Strength | 1800MPa - 2000MPa | 2000MPa - 2200MPa |

Coating Thickness | 50μm - 80μm (hot-dip zinc) | N/A (uncoated) |

Breaking Load | 5T - 45T | 6T - 50T |

Elongation at Break | ≤3% | ≤2.5% |

Operating Temperature | -40℃ to 120℃ | -40℃ to 150℃ |

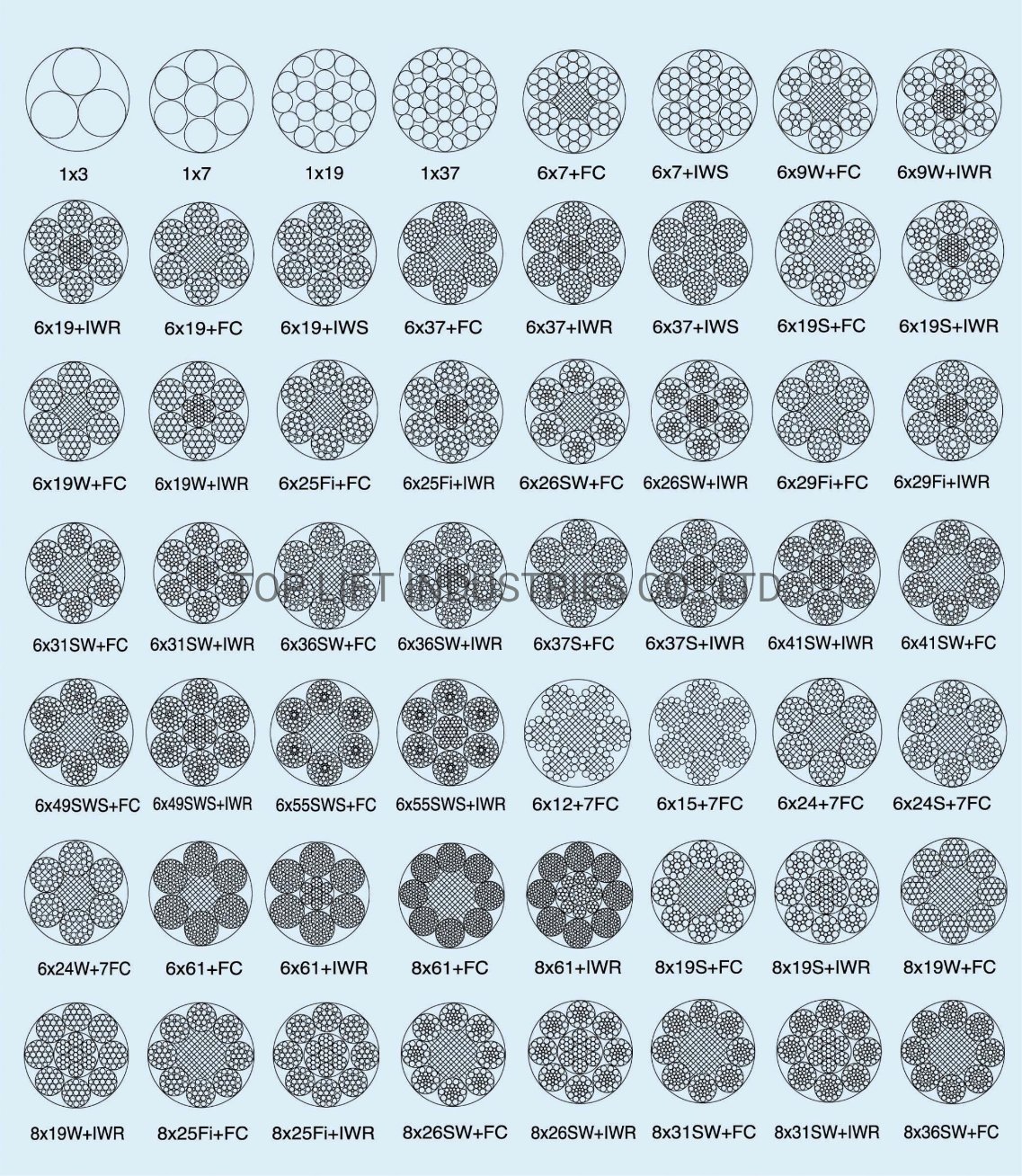

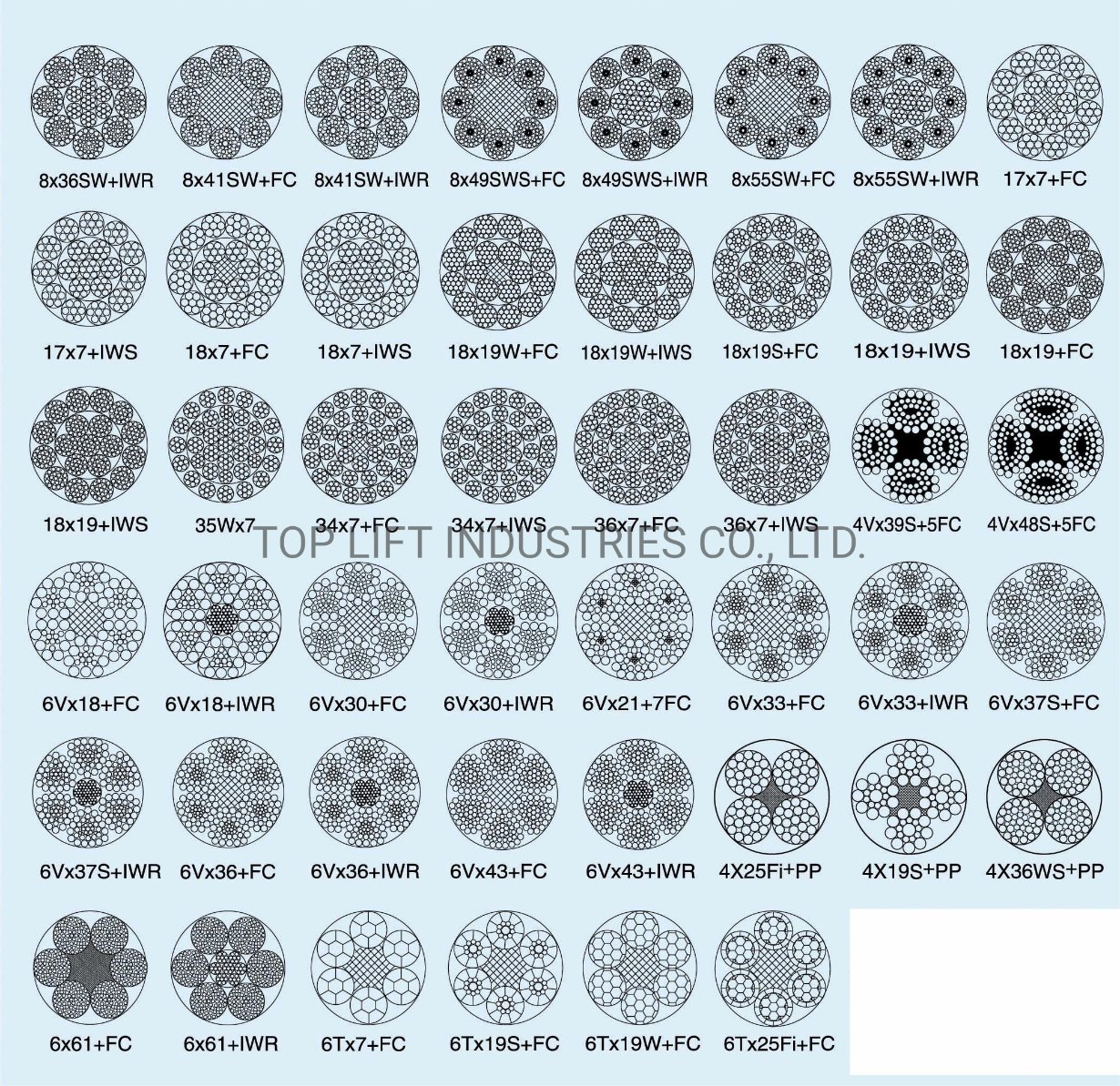

Typical Cross Sections Of Wire Rope&Strand

This line contact steel wire rope excels in scenarios requiring precision and durability:

Construction: Lifting steel beams, concrete components, and heavy machinery with tower cranes and mobile cranes.

Mining: Hoisting ore and equipment in underground mines, where the ungalvanized variant’s high strength resists abrasion from rock and dust.

Marine & Offshore: The galvanized variant is used for mooring ships and lifting offshore structures, as its zinc coating withstands saltwater corrosion.

Industrial Machinery: Compatible with winches, hoists, and conveyors in factories, particularly for assembly line material handling.

Infrastructure Maintenance: Repairing bridges and power lines, where the rope’s flexibility allows navigation through tight spaces.

Compatible equipment includes tower cranes, electric winches, mobile hoists, and conveyor systems from leading brands like Liebherr and Konecranes.

Packing: Each rope is coiled on wooden or steel reels (diameter 800mm - 1200mm) with waterproof plastic wrapping to prevent damage during shipping. Reels are labeled with product specs, batch number, and safety instructions.

Production Lead Time: 7 - 15 working days for standard orders; 20 - 30 days for custom diameters or lengths.

Services: Free sample testing (up to 2 meters per variant), technical consultation on rope selection, and a 12-month warranty for manufacturing defects. We also offer custom cutting to specific lengths (10m - 1000m) to reduce waste for buyers.

Galvanized rope has a zinc coating for corrosion resistance (best for outdoor/moist environments), while ungalvanized rope is uncoated pure steel with higher tensile strength (ideal for indoor/heavy-load scenarios).

Yes. Its line contact structure and high breaking load (up to 50T) meet safety standards for overhead lifting of heavy materials in construction and mining.

Absolutely. We issue ISO 9001 quality certificates and material test reports (MTR) for each batch, confirming compliance with line contact steel wire rope performance standards.

Galvanized & Ungalvanized Line Contact Steel Wire Rope is a high-performance lifting and transmission solution engineered for industrial durability and precision. Unlike ordinary wire ropes, its unique line contact structure ensures even load distribution, making it a top choice for heavy-duty operations where stability and longevity matter. Available in both galvanized (zinc-coated for corrosion resistance) and ungalvanized (pure steel for maximum strength) variants, this rope caters to diverse environmental and functional needs. It complies with international standards such as ISO and DIN, ensuring compatibility with global industrial equipment and meeting the strict requirements of professional buyers seeking reliable line contact steel wire rope for critical applications.

Dual-Coating Options: Choose between galvanized steel wire rope (zinc coating prevents rust in moist/harsh environments) and ungalvanized steel wire rope (uncoated pure steel delivers 15% higher tensile strength than galvanized alternatives).

Line Contact Structure: The specialized line contact design minimizes friction between strands, reducing wear and extending the rope’s service life by up to 30% compared to traditional point-contact ropes.

High Tensile Strength: Ranges from 1800MPa to 2200MPa, enabling safe lifting of heavy loads (5T to 50T) in construction and mining scenarios.

Flexible Operation: Maintains excellent flexibility even under dynamic loads, ensuring smooth winding and unwinding on winches and cranes without kinking.

Corrosion Resistance (Galvanized Variant): Hot-dip galvanization provides a thick, uniform zinc layer, making it suitable for outdoor, marine, or coastal applications where moisture is a concern.

Cost-Effective (Ungalvanized Variant): 20% lower cost than galvanized options, ideal for indoor or low-moisture environments where corrosion risk is minimal.

Specification | Galvanized Variant | Ungalvanized Variant |

Construction | 6×19W+FC, 6×36WS+IWRC | 6×19W+FC, 6×36WS+IWRC |

Diameter Range | 8mm - 40mm | 8mm - 40mm |

Tensile Strength | 1800MPa - 2000MPa | 2000MPa - 2200MPa |

Coating Thickness | 50μm - 80μm (hot-dip zinc) | N/A (uncoated) |

Breaking Load | 5T - 45T | 6T - 50T |

Elongation at Break | ≤3% | ≤2.5% |

Operating Temperature | -40℃ to 120℃ | -40℃ to 150℃ |

Typical Cross Sections Of Wire Rope&Strand

This line contact steel wire rope excels in scenarios requiring precision and durability:

Construction: Lifting steel beams, concrete components, and heavy machinery with tower cranes and mobile cranes.

Mining: Hoisting ore and equipment in underground mines, where the ungalvanized variant’s high strength resists abrasion from rock and dust.

Marine & Offshore: The galvanized variant is used for mooring ships and lifting offshore structures, as its zinc coating withstands saltwater corrosion.

Industrial Machinery: Compatible with winches, hoists, and conveyors in factories, particularly for assembly line material handling.

Infrastructure Maintenance: Repairing bridges and power lines, where the rope’s flexibility allows navigation through tight spaces.

Compatible equipment includes tower cranes, electric winches, mobile hoists, and conveyor systems from leading brands like Liebherr and Konecranes.

Packing: Each rope is coiled on wooden or steel reels (diameter 800mm - 1200mm) with waterproof plastic wrapping to prevent damage during shipping. Reels are labeled with product specs, batch number, and safety instructions.

Production Lead Time: 7 - 15 working days for standard orders; 20 - 30 days for custom diameters or lengths.

Services: Free sample testing (up to 2 meters per variant), technical consultation on rope selection, and a 12-month warranty for manufacturing defects. We also offer custom cutting to specific lengths (10m - 1000m) to reduce waste for buyers.

Galvanized rope has a zinc coating for corrosion resistance (best for outdoor/moist environments), while ungalvanized rope is uncoated pure steel with higher tensile strength (ideal for indoor/heavy-load scenarios).

Yes. Its line contact structure and high breaking load (up to 50T) meet safety standards for overhead lifting of heavy materials in construction and mining.

Absolutely. We issue ISO 9001 quality certificates and material test reports (MTR) for each batch, confirming compliance with line contact steel wire rope performance standards.