- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

9*17s+9*7+1W19

| Availability: | |

|---|---|

| Quantity: | |

The Braided Steel Cable (also known as Steel Wire Rope) is a high-performance lifting and securing tool engineered for reliability across industrial, construction, outdoor, and agricultural settings. Crafted from top-grade steel fibers, this Durable Braided Cable balances exceptional strength with impressive flexibility, making it an indispensable choice for heavy-duty tasks that demand stability and longevity. Whether you’re securing equipment, lifting machinery, or tractioning loads, this High-Strength Steel Wire product delivers consistent performance in even the most challenging environments, catering to both professional and industrial needs.

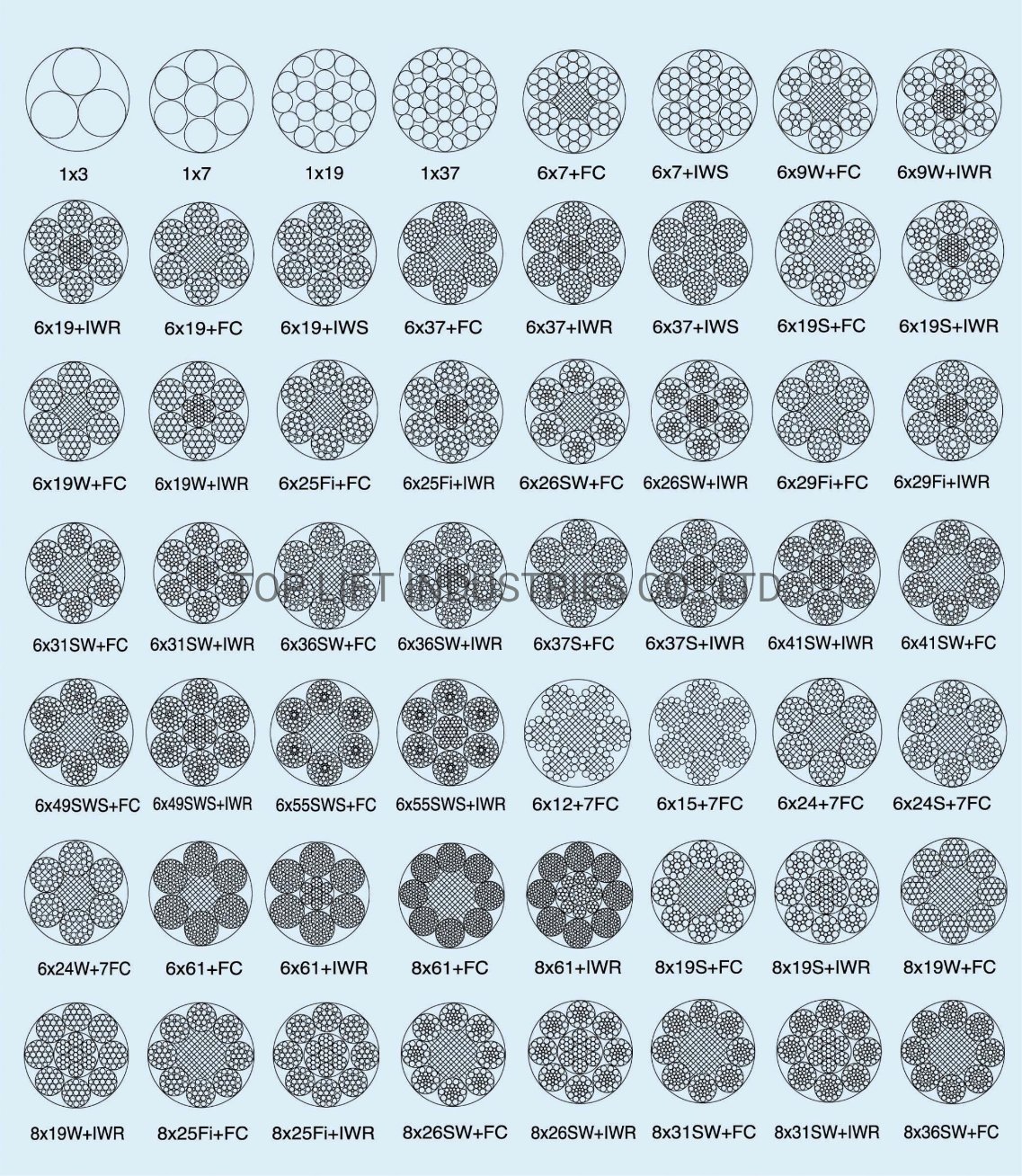

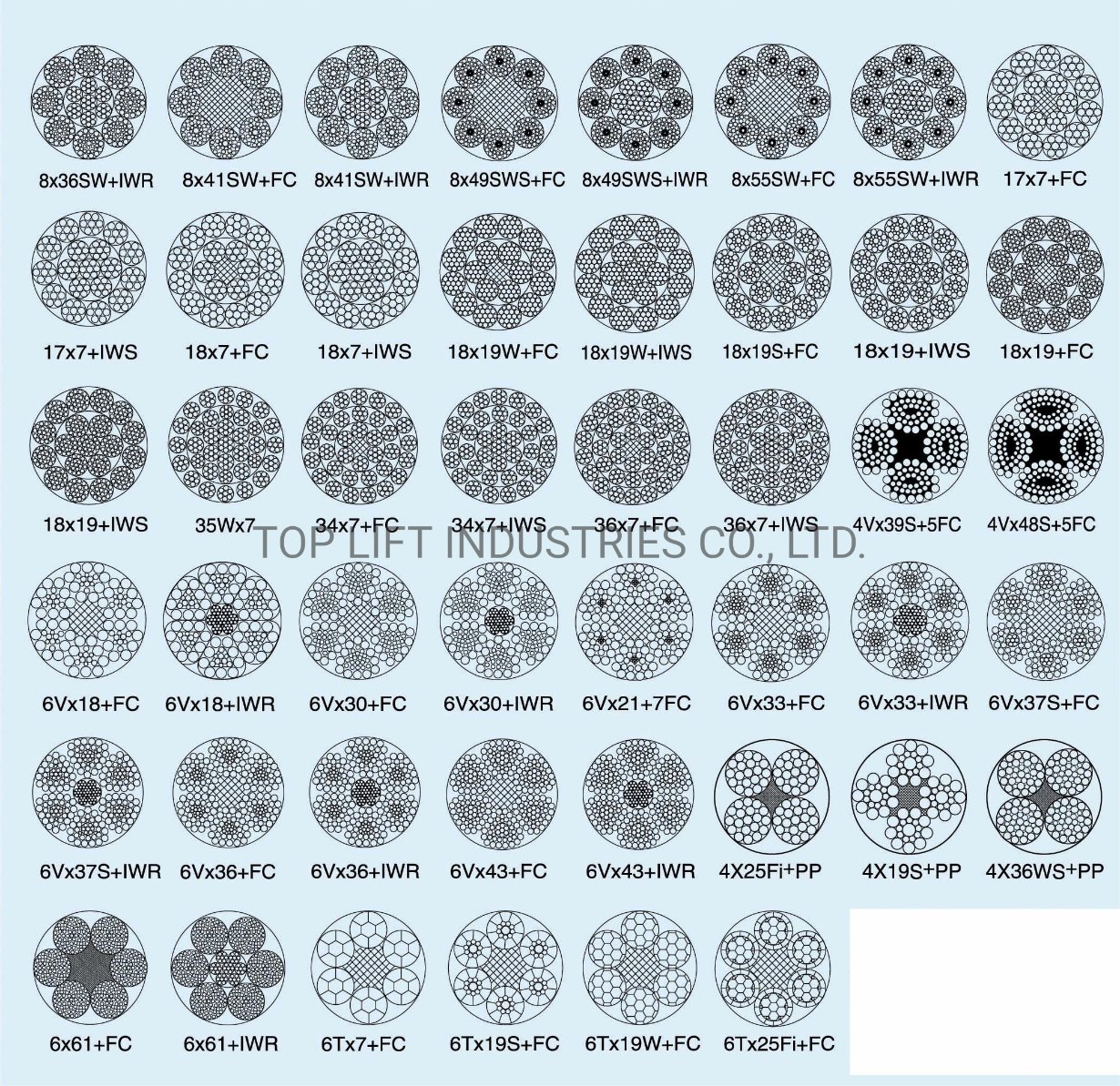

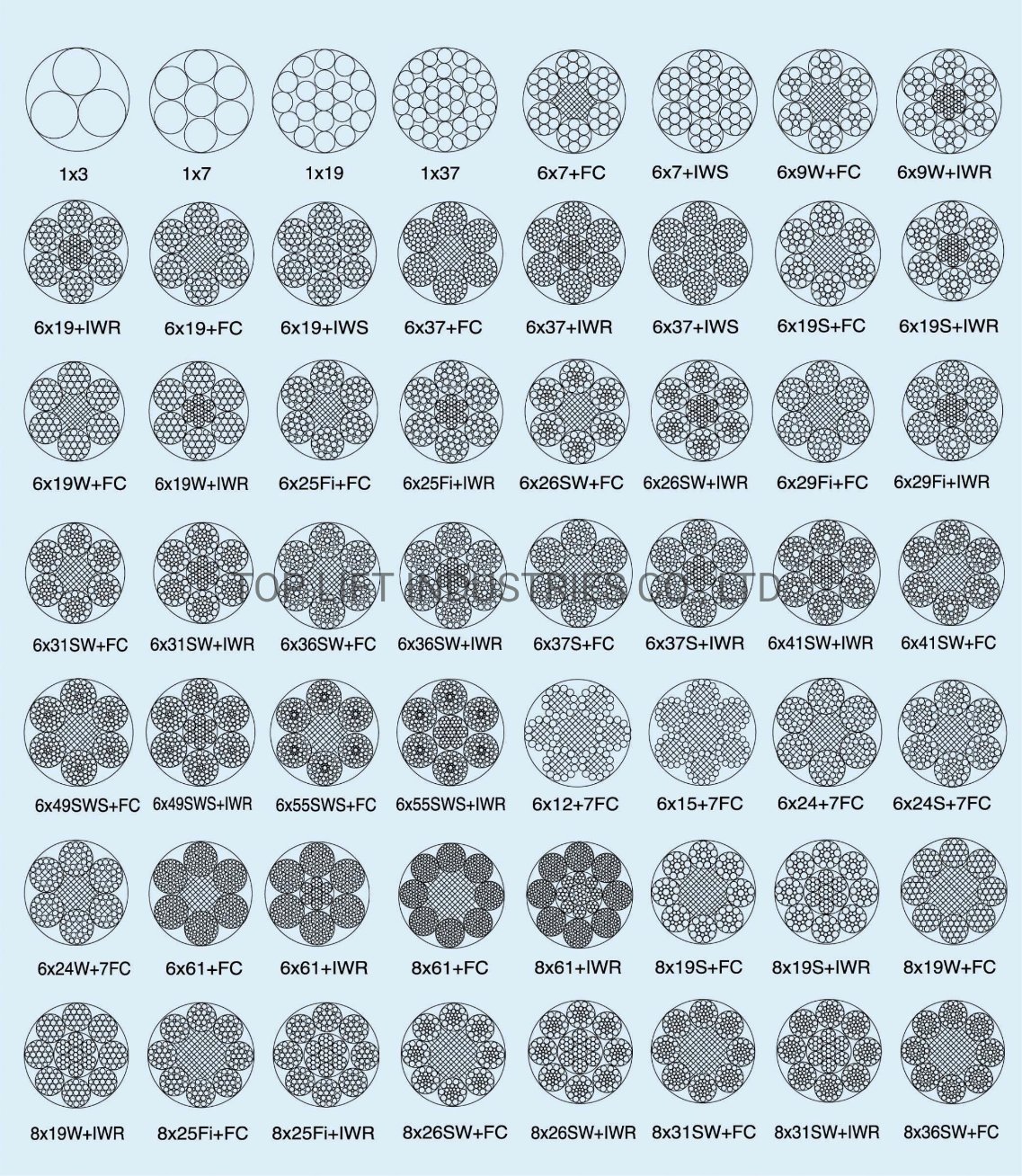

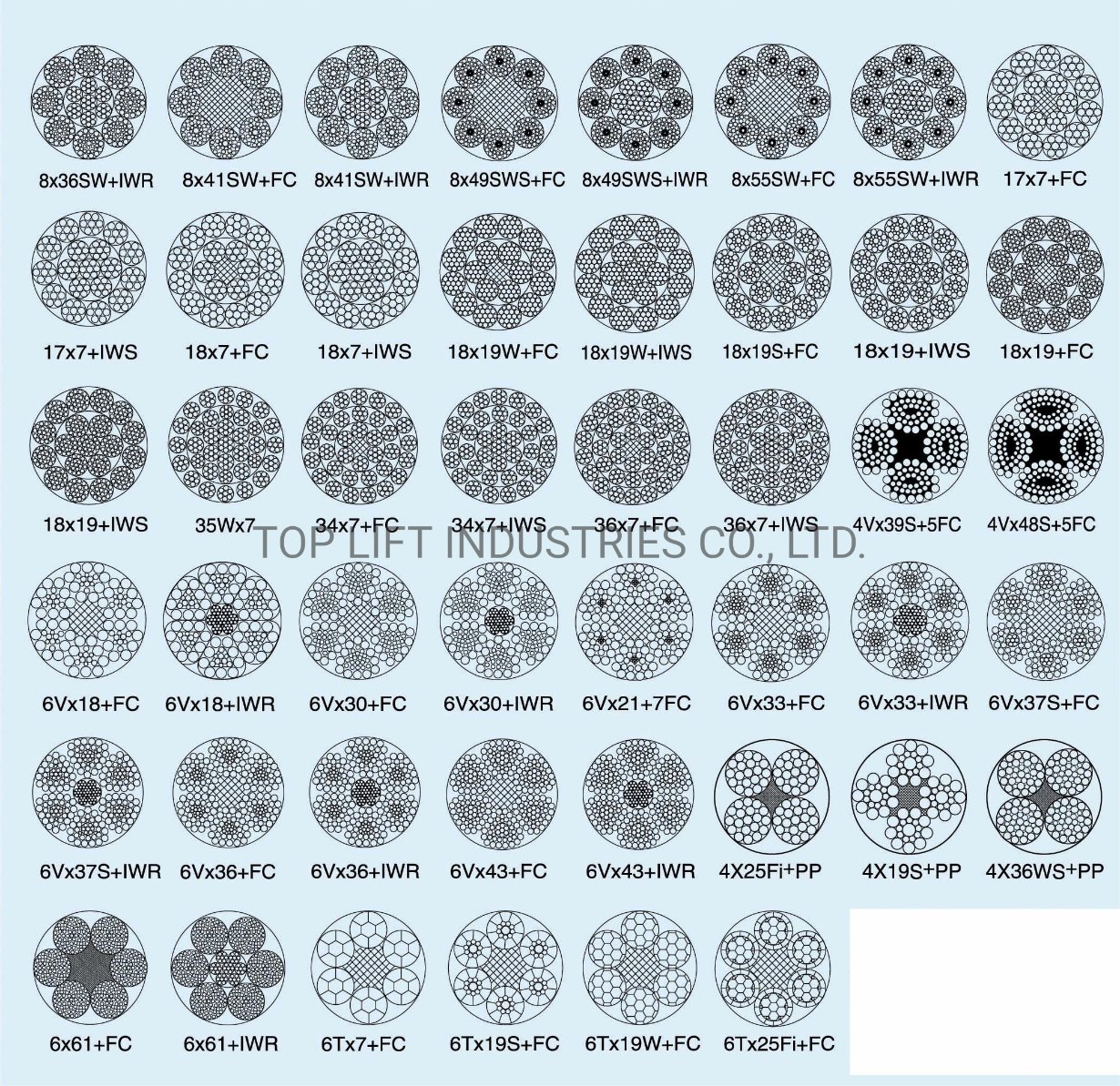

The cable features a tightly woven Braided Steel Wire design with a uniform texture, enhancing overall structural integrity and load-bearing capacity. The intricate braiding pattern ensures force is evenly distributed across the entire length, preventing weak points and ensuring consistent performance.

Undergoing a specialized surface finishing process, the Steel Wire Rope boasts a smooth exterior that minimizes friction. This not only protects the items being lifted or secured from scratches but also reduces wear on the cable itself during prolonged use.

Designed to be highly maneuverable, the Flexible Steel Cable can be easily bent, coiled, or wrapped around various shapes and surfaces. Its adaptable form eliminates the hassle of rigid tools, allowing for seamless integration into diverse work scenarios.

A durable, corrosion-resistant coating covers the exterior of the Wear-Resistant Braided Cable, shielding it from moisture, dust, and harsh weather conditions. This protective layer extends the product’s lifespan and maintains its performance in both indoor and outdoor environments.

Material | Carbon Steel |

Diameter Range | 6mm to 90mm |

Lay | Right interaction twist, Left interaction twist, Right direction twist, Left direction twist |

Tensile Strength | 1370/1470/1570/1670/ 1770/ 1870/1960/2160MPA |

Surface Treatment | Ungalvanized, Electro Galvanized, Hot Dip Galvanized, PVC Coated |

At its core, the High-Strength Steel Wire construction enables the cable to handle heavy loads without stretching, breaking, or deforming. This reliability is critical for industrial lifting, construction site securing, and other high-stakes applications where safety and consistency are non-negotiable.

Unlike rigid alternatives, the Flexible Steel Cable allows for effortless handling. Whether you’re threading it through tight spaces, wrapping around equipment, or suspending loads, the cable bends and adjusts with minimal effort, reducing labor time and improving work efficiency.

The combination of high-quality steel and advanced anti-corrosion treatment creates a Corrosion-Resistant Steel Cable that thrives in damp, humid, or outdoor settings. It resists rust and degradation, ensuring long-term performance even in coastal areas or industrial environments with chemical exposure.

This Versatile Steel Wire Rope is not limited to a single use case. It excels in industrial machinery installation, agricultural equipment traction, outdoor event setup, and residential securing tasks, making it a multi-functional tool for professionals across sectors.

The Durable Braided Cable requires minimal upkeep to retain its performance. Its wear-resistant and corrosion-resistant properties mean less frequent replacement, reducing long-term costs and downtime for users.

We source only premium-grade steel fibers that meet international industry standards. Each batch of raw materials undergoes rigorous testing to ensure purity, strength, and durability, laying the foundation for a high-quality final product.

Our manufacturing facilities follow strict quality control protocols, from the braiding process to surface treatment. Every step is monitored by skilled technicians to ensure consistent braiding density, uniform coating application, and flawless structural integrity.

Before leaving the factory, each Braided Steel Cable undergoes a series of stringent tests, including tension resistance, wear resistance, and corrosion resistance evaluations. Only products that pass all tests are approved for sale, guaranteeing reliability for end-users.

The product is certified to meet key industry safety and quality standards, ensuring compatibility and compliance in markets worldwide. This certification provides users with confidence that the cable adheres to the highest safety and performance benchmarks.

The Braided Steel Cable is ideal for industrial lifting, construction site equipment securing, agricultural machinery traction, outdoor event stage setup, residential heavy item moving, and marine equipment mooring. Its versatility makes it suitable for any task requiring high strength and flexibility.

After use, clean the cable’s surface with a dry cloth to remove dirt and moisture. Store it in a dry, ventilated area away from direct sunlight and corrosive substances. Regularly inspect the braiding for signs of fraying or damage, and avoid using the cable beyond its intended load capacity.

Yes, the cable can be cut to your desired length using professional cutting tools. To prevent fraying at the cut end, we recommend applying a metal ferrule or heat-shrinking tube after cutting. This simple step ensures the cable remains secure and maintains its structural integrity.

Absolutely. The cable’s anti-corrosion coating and high-quality steel construction make it resistant to saltwater and humid coastal environments. It will not rust or degrade quickly, making it a reliable choice for marine applications like boat mooring or coastal construction.

The Braided Steel Cable (also known as Steel Wire Rope) is a high-performance lifting and securing tool engineered for reliability across industrial, construction, outdoor, and agricultural settings. Crafted from top-grade steel fibers, this Durable Braided Cable balances exceptional strength with impressive flexibility, making it an indispensable choice for heavy-duty tasks that demand stability and longevity. Whether you’re securing equipment, lifting machinery, or tractioning loads, this High-Strength Steel Wire product delivers consistent performance in even the most challenging environments, catering to both professional and industrial needs.

The cable features a tightly woven Braided Steel Wire design with a uniform texture, enhancing overall structural integrity and load-bearing capacity. The intricate braiding pattern ensures force is evenly distributed across the entire length, preventing weak points and ensuring consistent performance.

Undergoing a specialized surface finishing process, the Steel Wire Rope boasts a smooth exterior that minimizes friction. This not only protects the items being lifted or secured from scratches but also reduces wear on the cable itself during prolonged use.

Designed to be highly maneuverable, the Flexible Steel Cable can be easily bent, coiled, or wrapped around various shapes and surfaces. Its adaptable form eliminates the hassle of rigid tools, allowing for seamless integration into diverse work scenarios.

A durable, corrosion-resistant coating covers the exterior of the Wear-Resistant Braided Cable, shielding it from moisture, dust, and harsh weather conditions. This protective layer extends the product’s lifespan and maintains its performance in both indoor and outdoor environments.

Material | Carbon Steel |

Diameter Range | 6mm to 90mm |

Lay | Right interaction twist, Left interaction twist, Right direction twist, Left direction twist |

Tensile Strength | 1370/1470/1570/1670/ 1770/ 1870/1960/2160MPA |

Surface Treatment | Ungalvanized, Electro Galvanized, Hot Dip Galvanized, PVC Coated |

At its core, the High-Strength Steel Wire construction enables the cable to handle heavy loads without stretching, breaking, or deforming. This reliability is critical for industrial lifting, construction site securing, and other high-stakes applications where safety and consistency are non-negotiable.

Unlike rigid alternatives, the Flexible Steel Cable allows for effortless handling. Whether you’re threading it through tight spaces, wrapping around equipment, or suspending loads, the cable bends and adjusts with minimal effort, reducing labor time and improving work efficiency.

The combination of high-quality steel and advanced anti-corrosion treatment creates a Corrosion-Resistant Steel Cable that thrives in damp, humid, or outdoor settings. It resists rust and degradation, ensuring long-term performance even in coastal areas or industrial environments with chemical exposure.

This Versatile Steel Wire Rope is not limited to a single use case. It excels in industrial machinery installation, agricultural equipment traction, outdoor event setup, and residential securing tasks, making it a multi-functional tool for professionals across sectors.

The Durable Braided Cable requires minimal upkeep to retain its performance. Its wear-resistant and corrosion-resistant properties mean less frequent replacement, reducing long-term costs and downtime for users.

We source only premium-grade steel fibers that meet international industry standards. Each batch of raw materials undergoes rigorous testing to ensure purity, strength, and durability, laying the foundation for a high-quality final product.

Our manufacturing facilities follow strict quality control protocols, from the braiding process to surface treatment. Every step is monitored by skilled technicians to ensure consistent braiding density, uniform coating application, and flawless structural integrity.

Before leaving the factory, each Braided Steel Cable undergoes a series of stringent tests, including tension resistance, wear resistance, and corrosion resistance evaluations. Only products that pass all tests are approved for sale, guaranteeing reliability for end-users.

The product is certified to meet key industry safety and quality standards, ensuring compatibility and compliance in markets worldwide. This certification provides users with confidence that the cable adheres to the highest safety and performance benchmarks.

The Braided Steel Cable is ideal for industrial lifting, construction site equipment securing, agricultural machinery traction, outdoor event stage setup, residential heavy item moving, and marine equipment mooring. Its versatility makes it suitable for any task requiring high strength and flexibility.

After use, clean the cable’s surface with a dry cloth to remove dirt and moisture. Store it in a dry, ventilated area away from direct sunlight and corrosive substances. Regularly inspect the braiding for signs of fraying or damage, and avoid using the cable beyond its intended load capacity.

Yes, the cable can be cut to your desired length using professional cutting tools. To prevent fraying at the cut end, we recommend applying a metal ferrule or heat-shrinking tube after cutting. This simple step ensures the cable remains secure and maintains its structural integrity.

Absolutely. The cable’s anti-corrosion coating and high-quality steel construction make it resistant to saltwater and humid coastal environments. It will not rust or degrade quickly, making it a reliable choice for marine applications like boat mooring or coastal construction.