- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

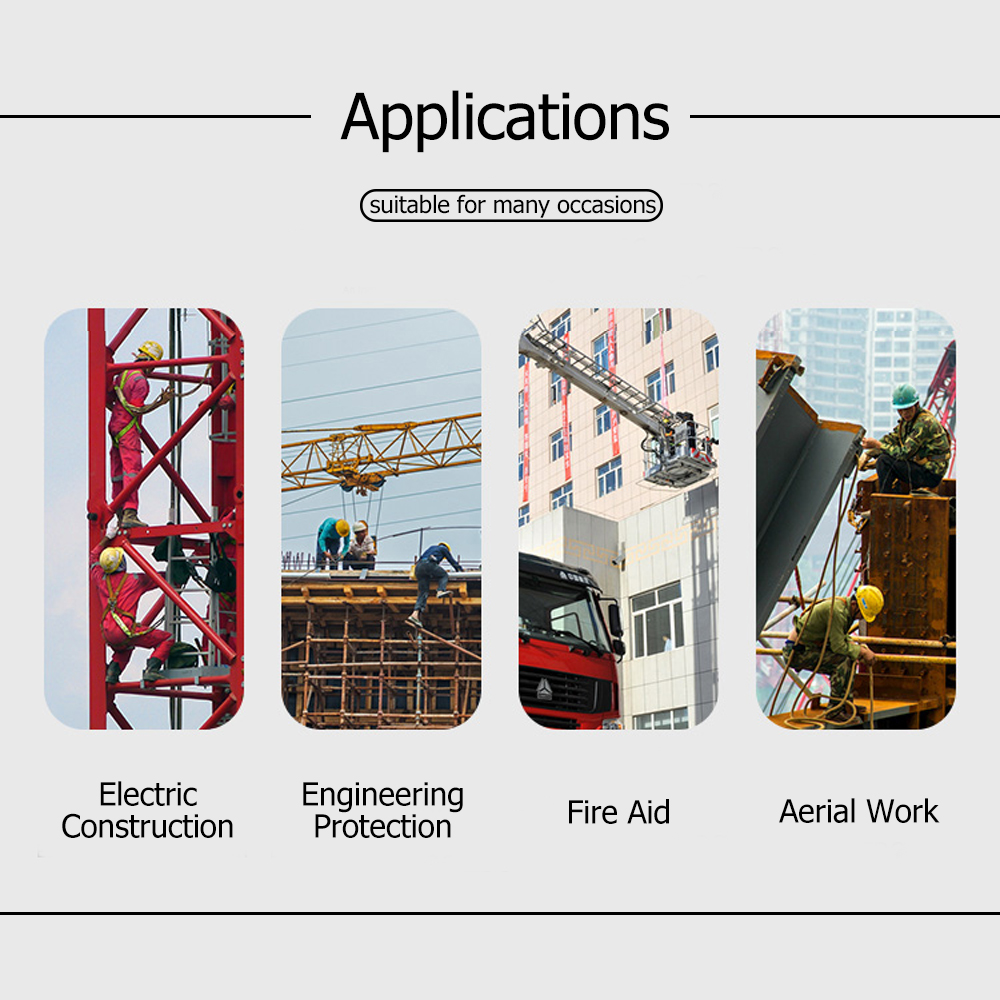

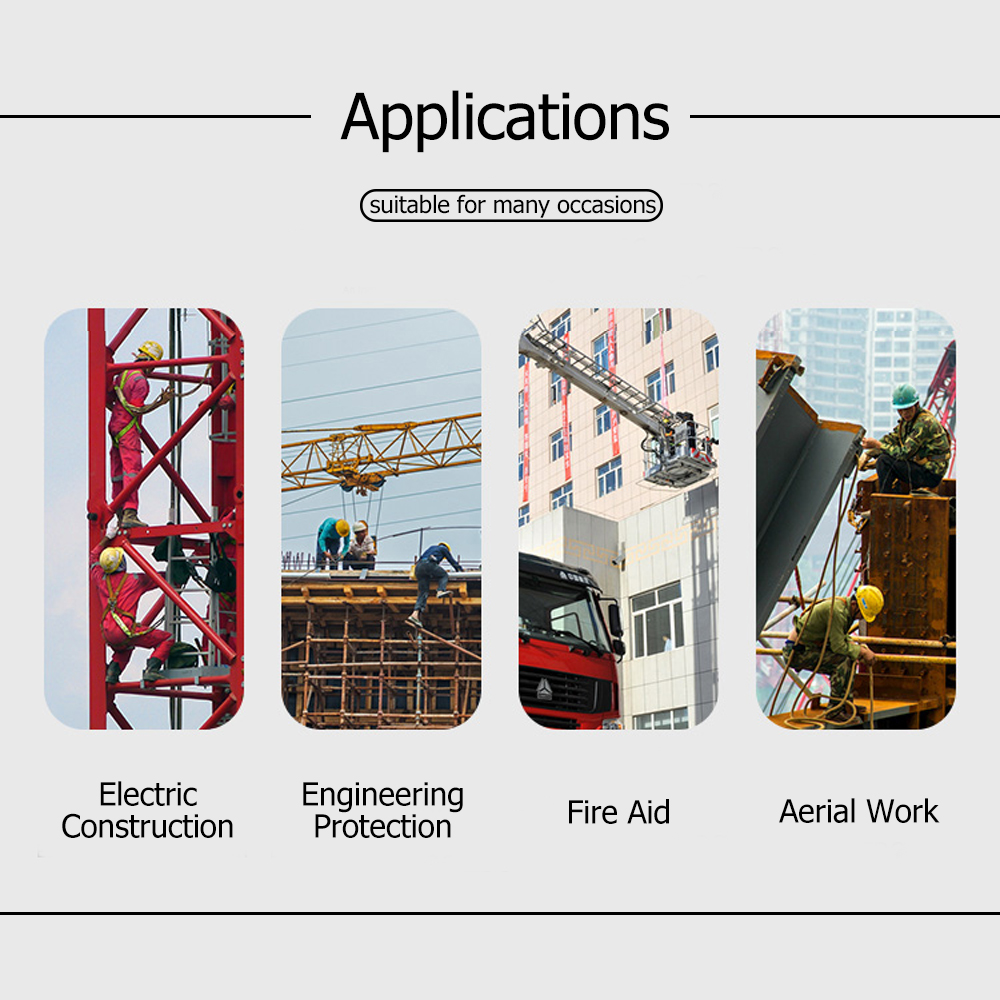

This EN certification harness is specifically designed to protect workers in industries such as construction, telecommunications, wind energy, and maintenance, where prolonged high-altitude work is common. It combines strict safety compliance with user-centric design, ensuring that workers stay protected without sacrificing comfort. As a certified industrial safety harness, it meets the rigorous requirements of EN standards, providing businesses with a trustworthy solution to meet workplace safety regulations and safeguard their most valuable asset—their employees.

The harness features strategically placed soft pad on the shoulders, waist, and thigh areas, which are the primary pressure points during extended wear. These pads are made of breathable, moisture-wicking fabric that reduces friction and distributes pressure evenly, preventing discomfort or chafing. The pads maintain their shape even after repeated use, ensuring long-term comfort for workers who wear the harness for hours at a time.

Equipped with multiple high-quality adjustment buckles, the ergonomic harness design allows for precise fitting to different body types. The chest, waist, and leg straps can be easily adjusted to achieve a snug yet flexible fit, ensuring that the harness stays in place during dynamic movements. The streamlined structure avoids unnecessary bulk, allowing workers to move freely without feeling restricted, whether climbing ladders, working on scaffolding, or performing maintenance tasks.

The main body of the harness is crafted from high-strength synthetic webbing that balances durability with lightweight performance. The material is resistant to tearing, abrasion, and UV radiation, making it suitable for outdoor and industrial environments. The metal components, including buckles and D-rings, are made of corrosion-resistant alloy, ensuring structural integrity and long service life. The overall design prioritizes both safety and practicality, with a clean, professional appearance that reflects its industrial-grade quality.

The integrated soft pad body harness addresses the common pain point of traditional harnesses—discomfort during prolonged use. The breathable pads reduce pressure on the body, preventing soreness and fatigue, which in turn improves worker productivity and focus. Unlike hard or thin padding, these soft pads conform to the body’s contours, providing a personalized fit that enhances overall wearing experience.

As an EN certification harness, this product has undergone rigorous testing to meet European safety standards for fall protection. The certification guarantees that the harness meets strict criteria for load-bearing capacity, impact resistance, and material safety, making it suitable for use in global workplaces that require compliance with international safety regulations. This certification not only ensures worker safety but also helps businesses avoid legal risks associated with non-compliant equipment.

The industrial-grade webbing and reinforced stitching make the durable body harness capable of withstanding the rigors of heavy-duty use. It resists damage from sharp objects, rough surfaces, and environmental factors, maintaining its structural integrity even in challenging work conditions. This durability translates to a longer service life, reducing the need for frequent replacements and lowering overall safety costs.

The intuitive adjustment system allows workers to customize the harness to their body size quickly. The buckles are easy to operate with one hand, even while wearing gloves, ensuring a secure fit that doesn’t shift during movement. A proper fit is crucial for fall protection, as it ensures the harness distributes impact force evenly across the body, minimizing injury risk.

The full-body design covers all critical areas, including the torso, legs, and shoulders, providing 360-degree protection during a fall. The D-rings are strategically positioned to ensure optimal force distribution, reducing stress on the spine and other vulnerable areas. Whether it’s a vertical fall or a slide, the harness keeps the worker in a safe position, minimizing the risk of serious injury.

The TP-SH3212 harness holds official EN certification, a testament to its compliance with European safety standards. This certification is awarded only after passing strict tests for load capacity, impact absorption, and material durability, ensuring that every unit meets the highest safety benchmarks.

All raw materials, from the webbing to the soft pads and metal components, undergo rigorous testing before production. The webbing is tested for tensile strength and tear resistance, while the pads are evaluated for breathability and durability. The metal parts are inspected for corrosion resistance and load-bearing capacity, ensuring that every component contributes to the harness’s overall safety.

The manufacturing process follows strict quality control protocols, with multiple inspections at each stage. From cutting and stitching to assembly and final testing, every step is supervised by experienced quality control personnel. Each harness is subjected to a final load test to confirm its ability to withstand fall impacts, ensuring that no defective products reach customers.

Refer to the detailed size chart provided, which includes measurements for waist, chest, and thigh circumference. Select a size that fits snugly but allows for comfortable movement—avoid sizes that are too loose (which may shift during a fall) or too tight (which can cause discomfort). If you’re between sizes, opt for the larger size and use the adjustment buckles to achieve a perfect fit. The comfortable safety harness should feel secure without restricting blood flow or movement.

Yes, the industrial safety harness is specifically designed for heavy-duty high-altitude operations. Its durable materials, reinforced stitching, and EN certification make it suitable for construction, mining, wind energy, and other industries where workers face high fall risks. It can withstand the demands of daily use in harsh environments, providing reliable protection for years.

Yes, the soft pads can be cleaned with mild detergent and warm water—avoid using harsh chemicals or bleach, as they may damage the fabric. After cleaning, air-dry the harness in a well-ventilated area, away from direct sunlight. Regular maintenance includes inspecting the webbing for fraying, the stitching for loose threads, and the buckles for smooth operation. Store the harness in a dry, cool place when not in use, and replace it immediately if any signs of damage are detected.

The EN certification itself does not expire, but it’s important to ensure that the harness is used within its service life (typically specified by the manufacturer). To verify the certification’s validity, check the certification label on the harness, which includes the certification number and issuing body. You can cross-verify this information with the relevant certification authority to confirm that the harness meets current standards.

This EN certification harness is specifically designed to protect workers in industries such as construction, telecommunications, wind energy, and maintenance, where prolonged high-altitude work is common. It combines strict safety compliance with user-centric design, ensuring that workers stay protected without sacrificing comfort. As a certified industrial safety harness, it meets the rigorous requirements of EN standards, providing businesses with a trustworthy solution to meet workplace safety regulations and safeguard their most valuable asset—their employees.

The harness features strategically placed soft pad on the shoulders, waist, and thigh areas, which are the primary pressure points during extended wear. These pads are made of breathable, moisture-wicking fabric that reduces friction and distributes pressure evenly, preventing discomfort or chafing. The pads maintain their shape even after repeated use, ensuring long-term comfort for workers who wear the harness for hours at a time.

Equipped with multiple high-quality adjustment buckles, the ergonomic harness design allows for precise fitting to different body types. The chest, waist, and leg straps can be easily adjusted to achieve a snug yet flexible fit, ensuring that the harness stays in place during dynamic movements. The streamlined structure avoids unnecessary bulk, allowing workers to move freely without feeling restricted, whether climbing ladders, working on scaffolding, or performing maintenance tasks.

The main body of the harness is crafted from high-strength synthetic webbing that balances durability with lightweight performance. The material is resistant to tearing, abrasion, and UV radiation, making it suitable for outdoor and industrial environments. The metal components, including buckles and D-rings, are made of corrosion-resistant alloy, ensuring structural integrity and long service life. The overall design prioritizes both safety and practicality, with a clean, professional appearance that reflects its industrial-grade quality.

The integrated soft pad body harness addresses the common pain point of traditional harnesses—discomfort during prolonged use. The breathable pads reduce pressure on the body, preventing soreness and fatigue, which in turn improves worker productivity and focus. Unlike hard or thin padding, these soft pads conform to the body’s contours, providing a personalized fit that enhances overall wearing experience.

As an EN certification harness, this product has undergone rigorous testing to meet European safety standards for fall protection. The certification guarantees that the harness meets strict criteria for load-bearing capacity, impact resistance, and material safety, making it suitable for use in global workplaces that require compliance with international safety regulations. This certification not only ensures worker safety but also helps businesses avoid legal risks associated with non-compliant equipment.

The industrial-grade webbing and reinforced stitching make the durable body harness capable of withstanding the rigors of heavy-duty use. It resists damage from sharp objects, rough surfaces, and environmental factors, maintaining its structural integrity even in challenging work conditions. This durability translates to a longer service life, reducing the need for frequent replacements and lowering overall safety costs.

The intuitive adjustment system allows workers to customize the harness to their body size quickly. The buckles are easy to operate with one hand, even while wearing gloves, ensuring a secure fit that doesn’t shift during movement. A proper fit is crucial for fall protection, as it ensures the harness distributes impact force evenly across the body, minimizing injury risk.

The full-body design covers all critical areas, including the torso, legs, and shoulders, providing 360-degree protection during a fall. The D-rings are strategically positioned to ensure optimal force distribution, reducing stress on the spine and other vulnerable areas. Whether it’s a vertical fall or a slide, the harness keeps the worker in a safe position, minimizing the risk of serious injury.

The TP-SH3212 harness holds official EN certification, a testament to its compliance with European safety standards. This certification is awarded only after passing strict tests for load capacity, impact absorption, and material durability, ensuring that every unit meets the highest safety benchmarks.

All raw materials, from the webbing to the soft pads and metal components, undergo rigorous testing before production. The webbing is tested for tensile strength and tear resistance, while the pads are evaluated for breathability and durability. The metal parts are inspected for corrosion resistance and load-bearing capacity, ensuring that every component contributes to the harness’s overall safety.

The manufacturing process follows strict quality control protocols, with multiple inspections at each stage. From cutting and stitching to assembly and final testing, every step is supervised by experienced quality control personnel. Each harness is subjected to a final load test to confirm its ability to withstand fall impacts, ensuring that no defective products reach customers.

Refer to the detailed size chart provided, which includes measurements for waist, chest, and thigh circumference. Select a size that fits snugly but allows for comfortable movement—avoid sizes that are too loose (which may shift during a fall) or too tight (which can cause discomfort). If you’re between sizes, opt for the larger size and use the adjustment buckles to achieve a perfect fit. The comfortable safety harness should feel secure without restricting blood flow or movement.

Yes, the industrial safety harness is specifically designed for heavy-duty high-altitude operations. Its durable materials, reinforced stitching, and EN certification make it suitable for construction, mining, wind energy, and other industries where workers face high fall risks. It can withstand the demands of daily use in harsh environments, providing reliable protection for years.

Yes, the soft pads can be cleaned with mild detergent and warm water—avoid using harsh chemicals or bleach, as they may damage the fabric. After cleaning, air-dry the harness in a well-ventilated area, away from direct sunlight. Regular maintenance includes inspecting the webbing for fraying, the stitching for loose threads, and the buckles for smooth operation. Store the harness in a dry, cool place when not in use, and replace it immediately if any signs of damage are detected.

The EN certification itself does not expire, but it’s important to ensure that the harness is used within its service life (typically specified by the manufacturer). To verify the certification’s validity, check the certification label on the harness, which includes the certification number and issuing body. You can cross-verify this information with the relevant certification authority to confirm that the harness meets current standards.