- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

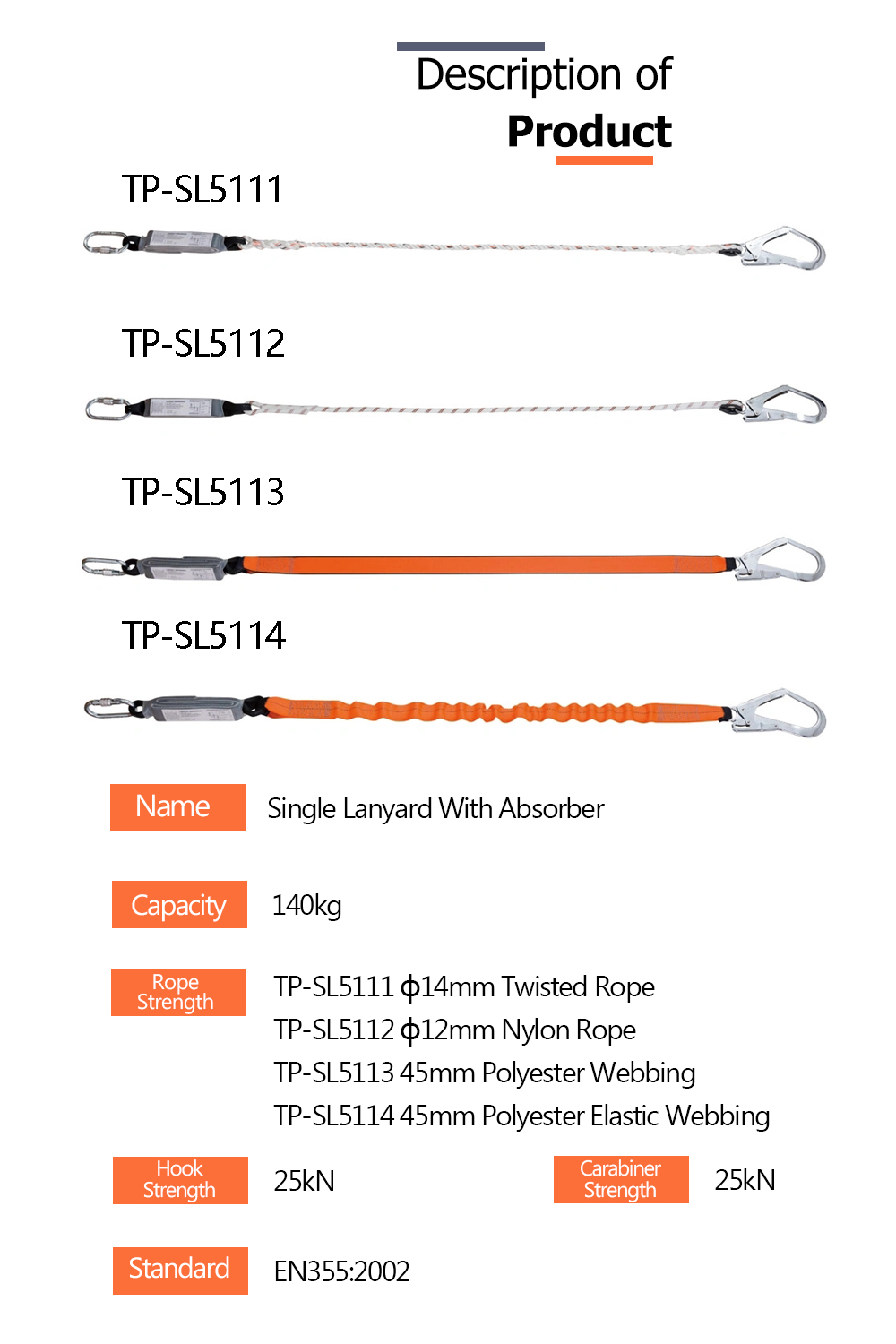

Model | TP-SL5111/5112/5113/5114 |

Capacity | 140Kg |

Rope Material | TP-SL5111Φ14mm Twisted Rope TP-SL5112Φ12mm Nylon Rope TP-SL5113 45mm Polyester Webbing TP-SL5114 45mm Polyester Elastic Webbing |

Hook Strength | 25kN |

Carabiner Strength | 25kN |

Available Length | 1.5m, 1.8m, 2.0m |

| Standard | EN355:2002 |

The appearance of the TP-SL5111/5112/5113/5114 fall protection lanyard is tailored to both functionality and practicality, with clear differentiation between models to suit specific work needs.

Each model features unique core materials optimized for different scenarios:

• TP-SL5111: Uses Φ14mm twisted rope, which boasts excellent tensile strength and wear resistance. Its tight twist structure prevents fraying, making it ideal for heavy-duty industrial settings where the lanyard may come into contact with rough surfaces.

• TP-SL5112: Adopts Φ12mm nylon rope, known for its lightweight and water-resistant properties. This material keeps the lanyard easy to carry without sacrificing durability, perfect for indoor maintenance or light outdoor work.

• TP-SL5113: Equipped with 45mm polyester webbing—thick, flat, and non-slip. The webbing’s wide surface reduces pressure on the user’s body, enhancing comfort during long-hour use, such as in bridge construction.

• TP-SL5114: Features 45mm polyester elastic webbing. The elasticity allows for slight movement without compromising safety, making it suitable for dynamic tasks like window cleaning or telecom tower maintenance.

All models offer three length options to match different work heights: 1.5m, 1.8m, and 2.0m. The compact design when folded ensures easy storage in tool bags, while the bright color (standard safety orange) improves visibility—critical for low-light environments like underground mines or evening construction.

Each lanyard has a laser-engraved model number (e.g., “TP-SL5111”) and load capacity label near the hardware. This allows workers to quickly confirm the lanyard’s suitability for their task, avoiding misuse and enhancing on-site safety efficiency.

The TP-SL5111/5112/5113/5114 lanyard’s mechanism is engineered to prioritize shock absorption and load-bearing stability, addressing the core risk of falls in high-altitude work.

At the heart of the lanyard is a built-in shock absorber—a key component that sets it apart from basic lanyards. When a fall occurs, the absorber stretches gradually to dissipate impact force, reducing the stress on the user’s body to below harmful levels. Unlike rigid safety gear, this flexible mechanism minimizes the risk of spinal or joint injuries, even during sudden falls.

The lanyard’s load-bearing system relies on high-strength connections between the rope/webbing and hardware:

• Both the snap hook and carabiner have a rated strength of 25kN—far exceeding the 140Kg maximum load capacity of the lanyard. This safety redundancy ensures the hardware won’t fail even under unexpected stress, such as a worker carrying tools while attached.

• The rope/webbing is stitched or crimped to the hardware using industrial-grade techniques, with no loose threads or weak points. This structure prevents accidental detachment, a common cause of safety incidents in low-quality lanyards.

The lanyard’s design simplifies daily use without compromising safety:

• The snap hook features a one-handed locking system. Workers can easily attach it to anchor points (like safety rails or harnesses) with one hand, even while wearing gloves—saving time and reducing the risk of unprotected exposure during attachment.

• The carabiner has a spring-loaded gate that closes automatically, eliminating the need for manual locking. This passive safety feature ensures the carabiner stays secure, even if the user forgets to lock it.

Every component of the TP-SL5111/5112/5113/5114 lanyard meets or exceeds international safety standards, ensuring consistency and reliability across all units.

The lanyard is fully compliant with EN355:2002—the European standard for shock-absorbing lanyards for fall protection. This means:

• The shock absorber’s performance is tested to limit impact force to ≤6 kN, as required by EN355:2002.

• The lanyard undergoes rigorous durability tests, including 500 cycles of load application and environmental tests (resistance to water, oil, and extreme temperatures), ensuring it performs well in harsh conditions.

All hardware parts are made from forged alloy steel, a material chosen for its high tensile strength and corrosion resistance:

• The snap hook and carabiner are treated with a zinc-plated finish, which prevents rusting—critical for offshore or humid environments where metal components are prone to corrosion.

• The hardware’s surface is smooth with no sharp edges, avoiding scratches on workers’ clothing or harnesses, and reducing wear on the lanyard itself.

Small but essential accessories further extend the lanyard’s lifespan:

• A wear-resistant sleeve covers the part of the rope/webbing that’s most likely to rub against anchor points. This sleeve reduces friction, preventing premature fraying and extending the lanyard’s service life by up to 30%.

• A dust cap is attached to the snap hook’s gate. It keeps dirt and debris out of the locking mechanism, ensuring smooth operation even in dusty work sites like construction yards or mines.

Model | TP-SL5111/5112/5113/5114 |

Capacity | 140Kg |

Rope Material | TP-SL5111Φ14mm Twisted Rope TP-SL5112Φ12mm Nylon Rope TP-SL5113 45mm Polyester Webbing TP-SL5114 45mm Polyester Elastic Webbing |

Hook Strength | 25kN |

Carabiner Strength | 25kN |

Available Length | 1.5m, 1.8m, 2.0m |

| Standard | EN355:2002 |

The appearance of the TP-SL5111/5112/5113/5114 fall protection lanyard is tailored to both functionality and practicality, with clear differentiation between models to suit specific work needs.

Each model features unique core materials optimized for different scenarios:

• TP-SL5111: Uses Φ14mm twisted rope, which boasts excellent tensile strength and wear resistance. Its tight twist structure prevents fraying, making it ideal for heavy-duty industrial settings where the lanyard may come into contact with rough surfaces.

• TP-SL5112: Adopts Φ12mm nylon rope, known for its lightweight and water-resistant properties. This material keeps the lanyard easy to carry without sacrificing durability, perfect for indoor maintenance or light outdoor work.

• TP-SL5113: Equipped with 45mm polyester webbing—thick, flat, and non-slip. The webbing’s wide surface reduces pressure on the user’s body, enhancing comfort during long-hour use, such as in bridge construction.

• TP-SL5114: Features 45mm polyester elastic webbing. The elasticity allows for slight movement without compromising safety, making it suitable for dynamic tasks like window cleaning or telecom tower maintenance.

All models offer three length options to match different work heights: 1.5m, 1.8m, and 2.0m. The compact design when folded ensures easy storage in tool bags, while the bright color (standard safety orange) improves visibility—critical for low-light environments like underground mines or evening construction.

Each lanyard has a laser-engraved model number (e.g., “TP-SL5111”) and load capacity label near the hardware. This allows workers to quickly confirm the lanyard’s suitability for their task, avoiding misuse and enhancing on-site safety efficiency.

The TP-SL5111/5112/5113/5114 lanyard’s mechanism is engineered to prioritize shock absorption and load-bearing stability, addressing the core risk of falls in high-altitude work.

At the heart of the lanyard is a built-in shock absorber—a key component that sets it apart from basic lanyards. When a fall occurs, the absorber stretches gradually to dissipate impact force, reducing the stress on the user’s body to below harmful levels. Unlike rigid safety gear, this flexible mechanism minimizes the risk of spinal or joint injuries, even during sudden falls.

The lanyard’s load-bearing system relies on high-strength connections between the rope/webbing and hardware:

• Both the snap hook and carabiner have a rated strength of 25kN—far exceeding the 140Kg maximum load capacity of the lanyard. This safety redundancy ensures the hardware won’t fail even under unexpected stress, such as a worker carrying tools while attached.

• The rope/webbing is stitched or crimped to the hardware using industrial-grade techniques, with no loose threads or weak points. This structure prevents accidental detachment, a common cause of safety incidents in low-quality lanyards.

The lanyard’s design simplifies daily use without compromising safety:

• The snap hook features a one-handed locking system. Workers can easily attach it to anchor points (like safety rails or harnesses) with one hand, even while wearing gloves—saving time and reducing the risk of unprotected exposure during attachment.

• The carabiner has a spring-loaded gate that closes automatically, eliminating the need for manual locking. This passive safety feature ensures the carabiner stays secure, even if the user forgets to lock it.

Every component of the TP-SL5111/5112/5113/5114 lanyard meets or exceeds international safety standards, ensuring consistency and reliability across all units.

The lanyard is fully compliant with EN355:2002—the European standard for shock-absorbing lanyards for fall protection. This means:

• The shock absorber’s performance is tested to limit impact force to ≤6 kN, as required by EN355:2002.

• The lanyard undergoes rigorous durability tests, including 500 cycles of load application and environmental tests (resistance to water, oil, and extreme temperatures), ensuring it performs well in harsh conditions.

All hardware parts are made from forged alloy steel, a material chosen for its high tensile strength and corrosion resistance:

• The snap hook and carabiner are treated with a zinc-plated finish, which prevents rusting—critical for offshore or humid environments where metal components are prone to corrosion.

• The hardware’s surface is smooth with no sharp edges, avoiding scratches on workers’ clothing or harnesses, and reducing wear on the lanyard itself.

Small but essential accessories further extend the lanyard’s lifespan:

• A wear-resistant sleeve covers the part of the rope/webbing that’s most likely to rub against anchor points. This sleeve reduces friction, preventing premature fraying and extending the lanyard’s service life by up to 30%.

• A dust cap is attached to the snap hook’s gate. It keeps dirt and debris out of the locking mechanism, ensuring smooth operation even in dusty work sites like construction yards or mines.