- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

6X25FI+FC 6X25FIIWR 6X26SW+FC 6X26SW+IWR 6X29FI+FC 6X31SW+FC 6X36SW+FC 6X36SW+IWR 6X37S+FC 6X37SW+IWR 6X41SW+FC 6X49SWS+FC 6X55SWS+FC 6X55SWS+IWR

| Availability: | |

|---|---|

| Quantity: | |

Wire rope is used to increase the support of suspension bridges, elevators, and as an additional reinforcement of towers. The design of wire rope, with its multiple strands wrapped around a stable core, provides strength, flexibility, and ease of handling for applications that have bending stress.

Features:

1. The wire rope can transmit long-distance load.

2. The bearing safety factor is large, and the use is safe and reliable.

3. Light weight, easy to carry and transport.

4. Able to withstand various loads and variable loads.

5. It has high tensile strength, fatigue strength and impact toughness.

6. Under high-speed working conditions, it is abrasion-resistant, shock-resistant and stable in operation.

7. Good corrosion resistance, able to work normally in the harsh environment of various harmful media.

8. Good softness, suitable for traction, pulling, strapping and other purposes.

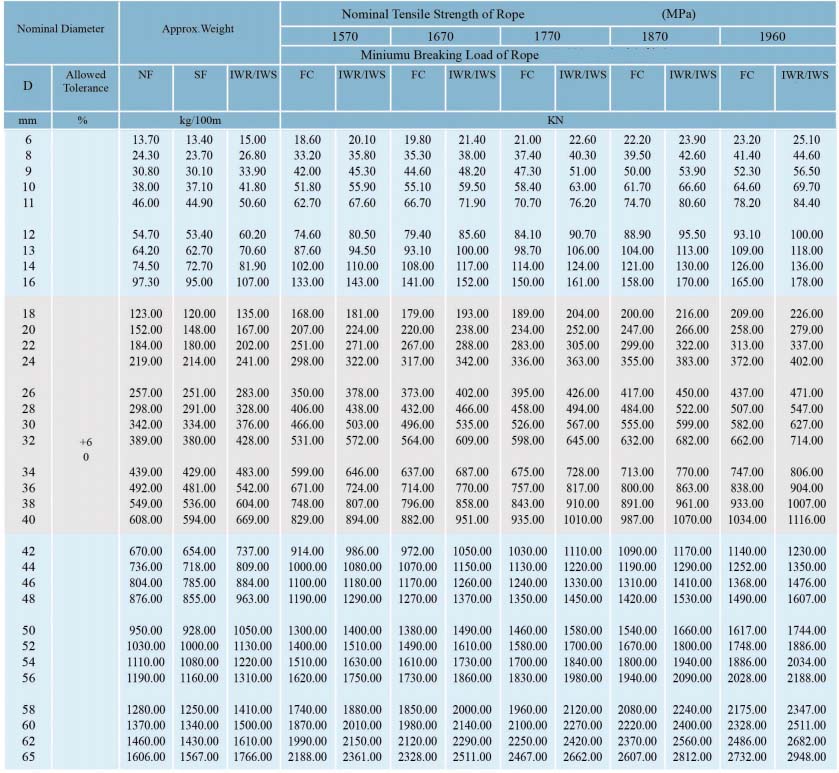

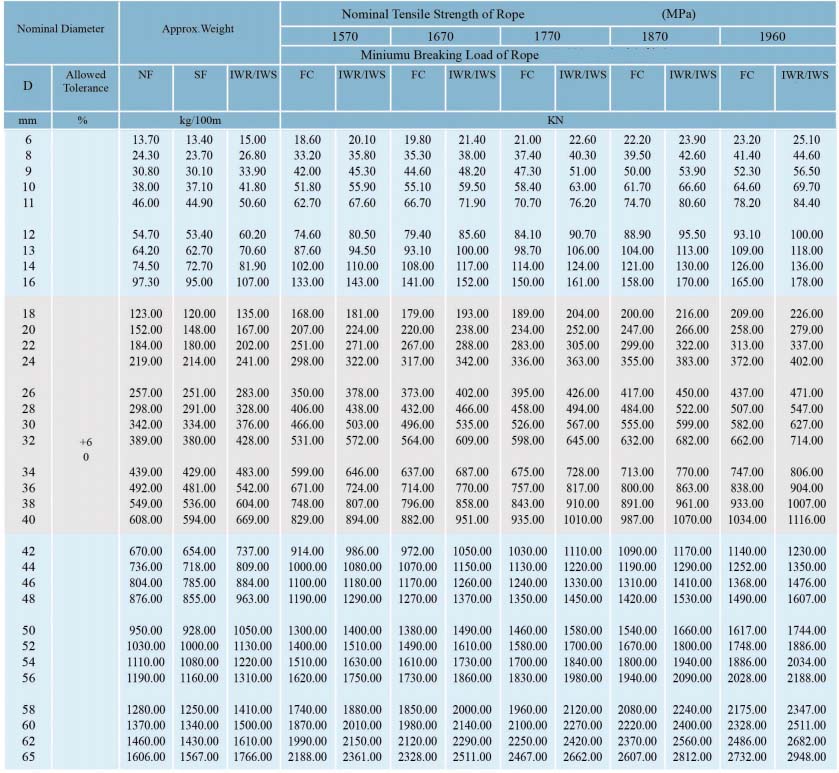

Technical Parameter

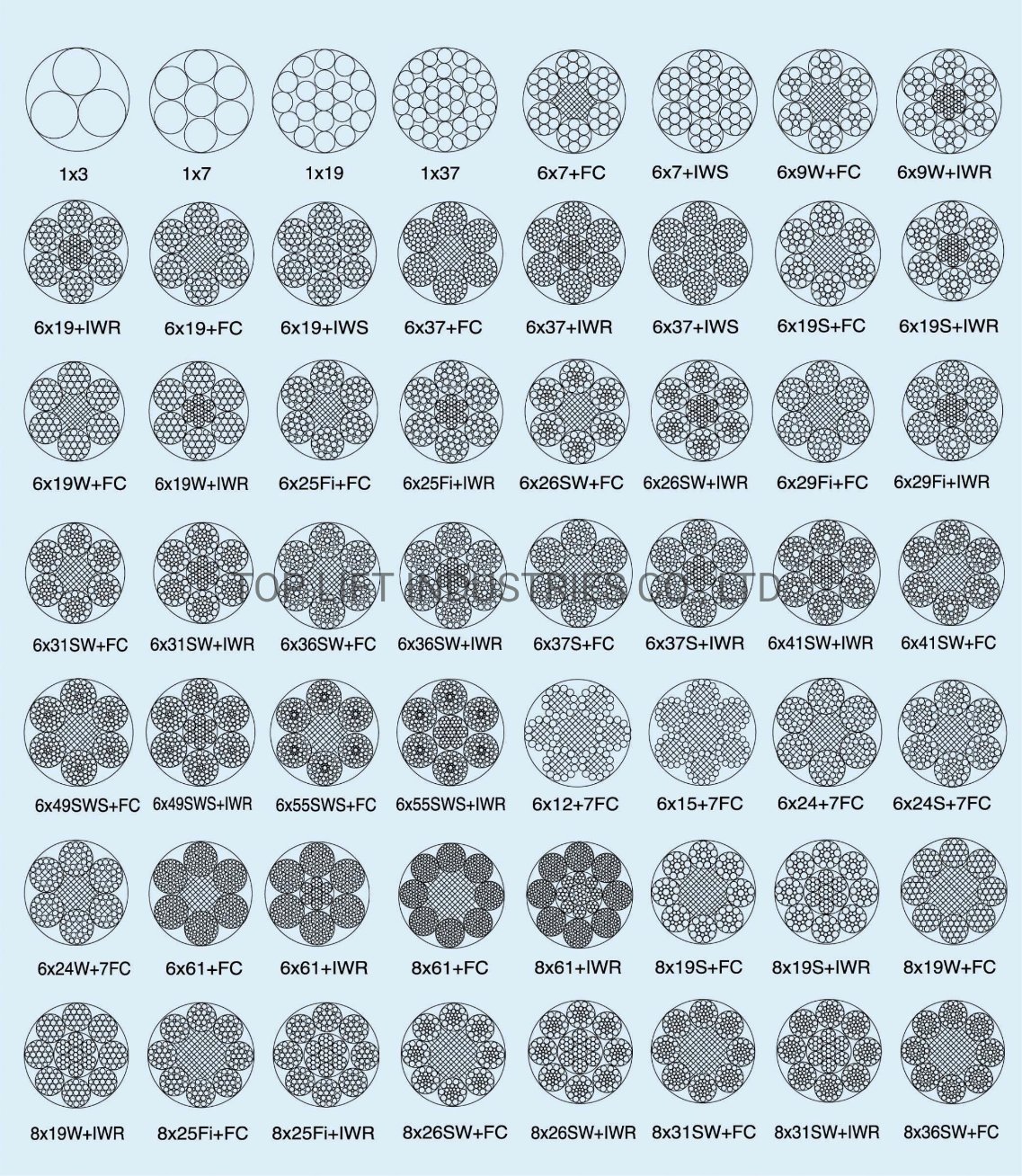

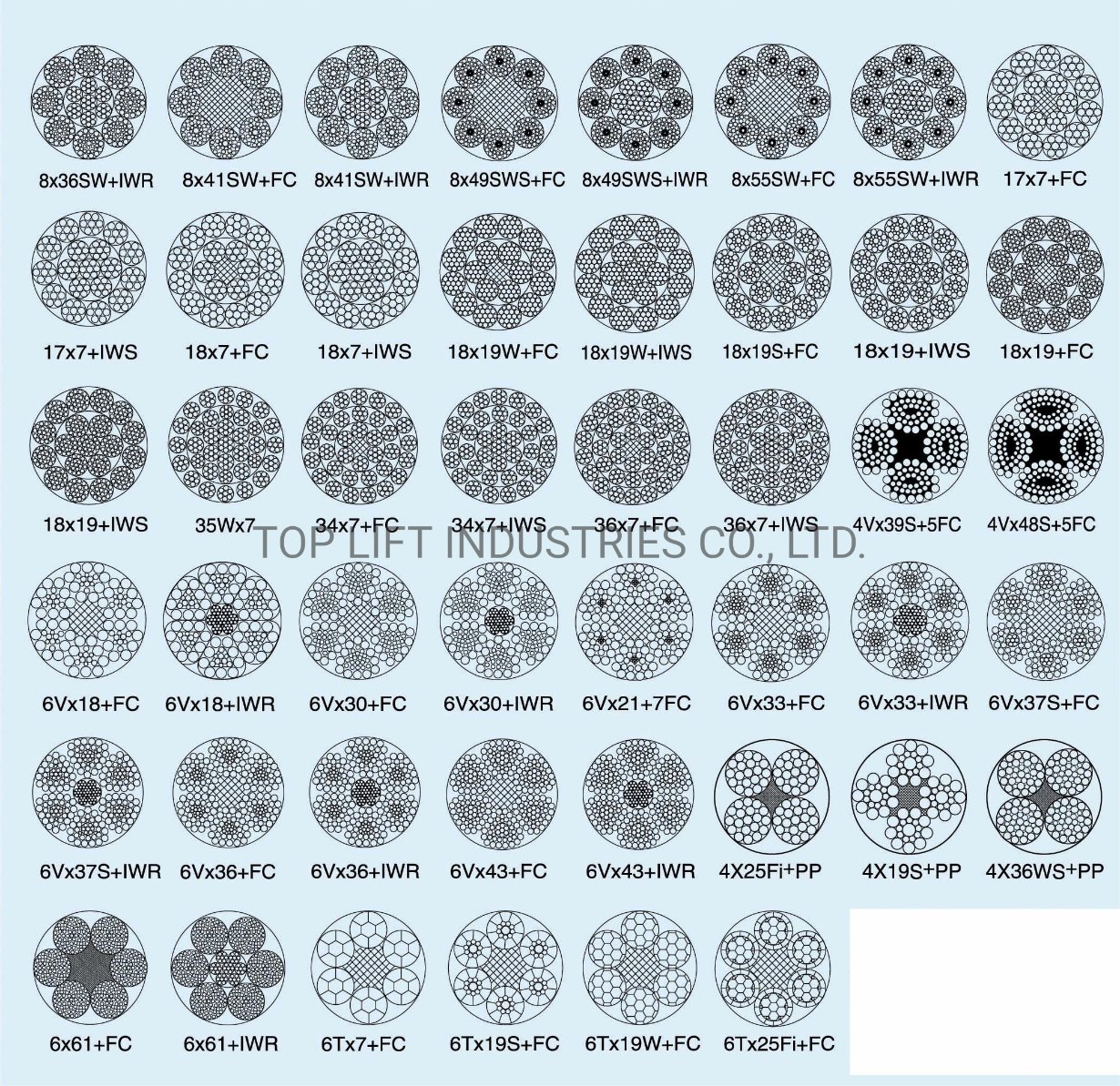

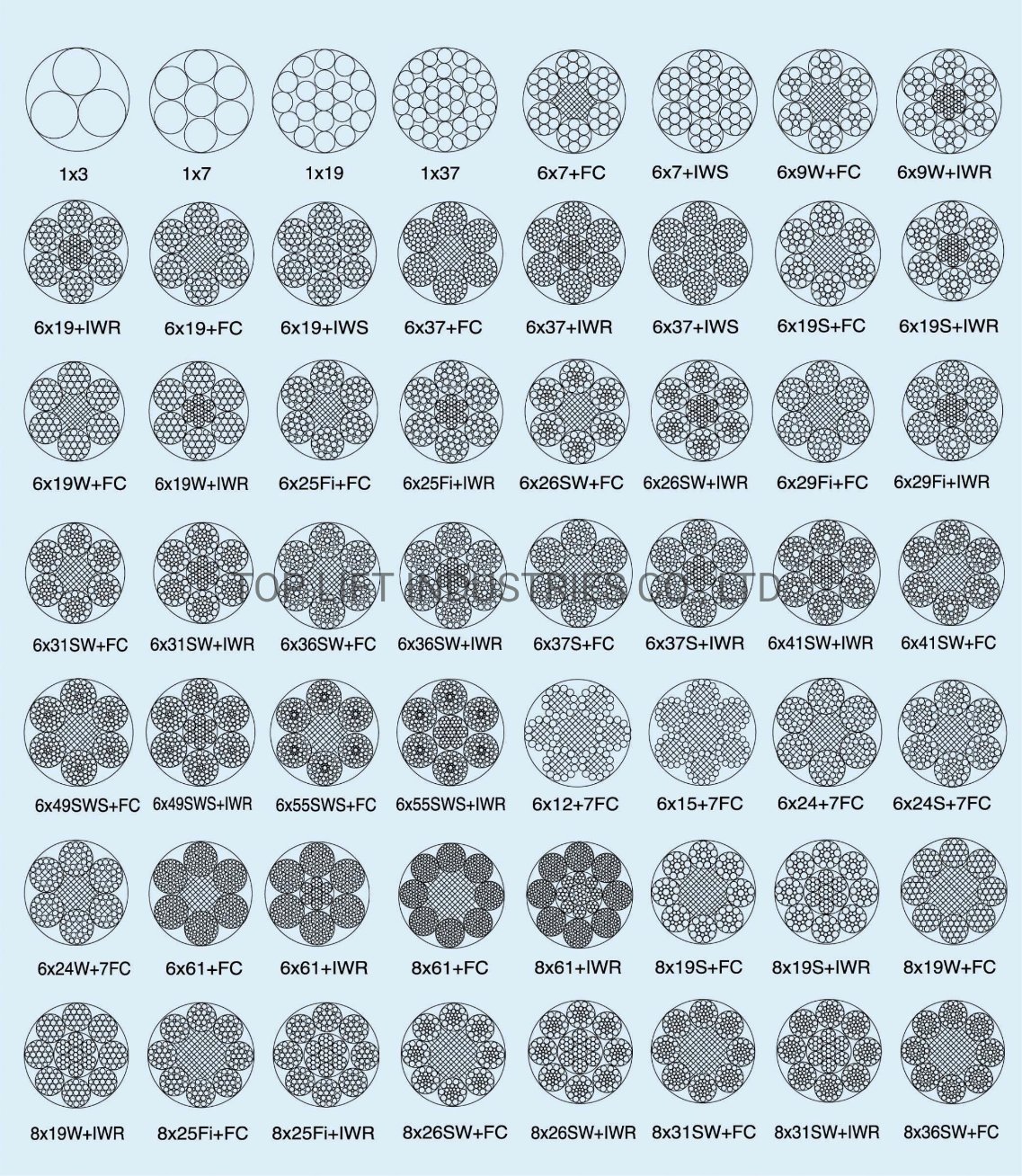

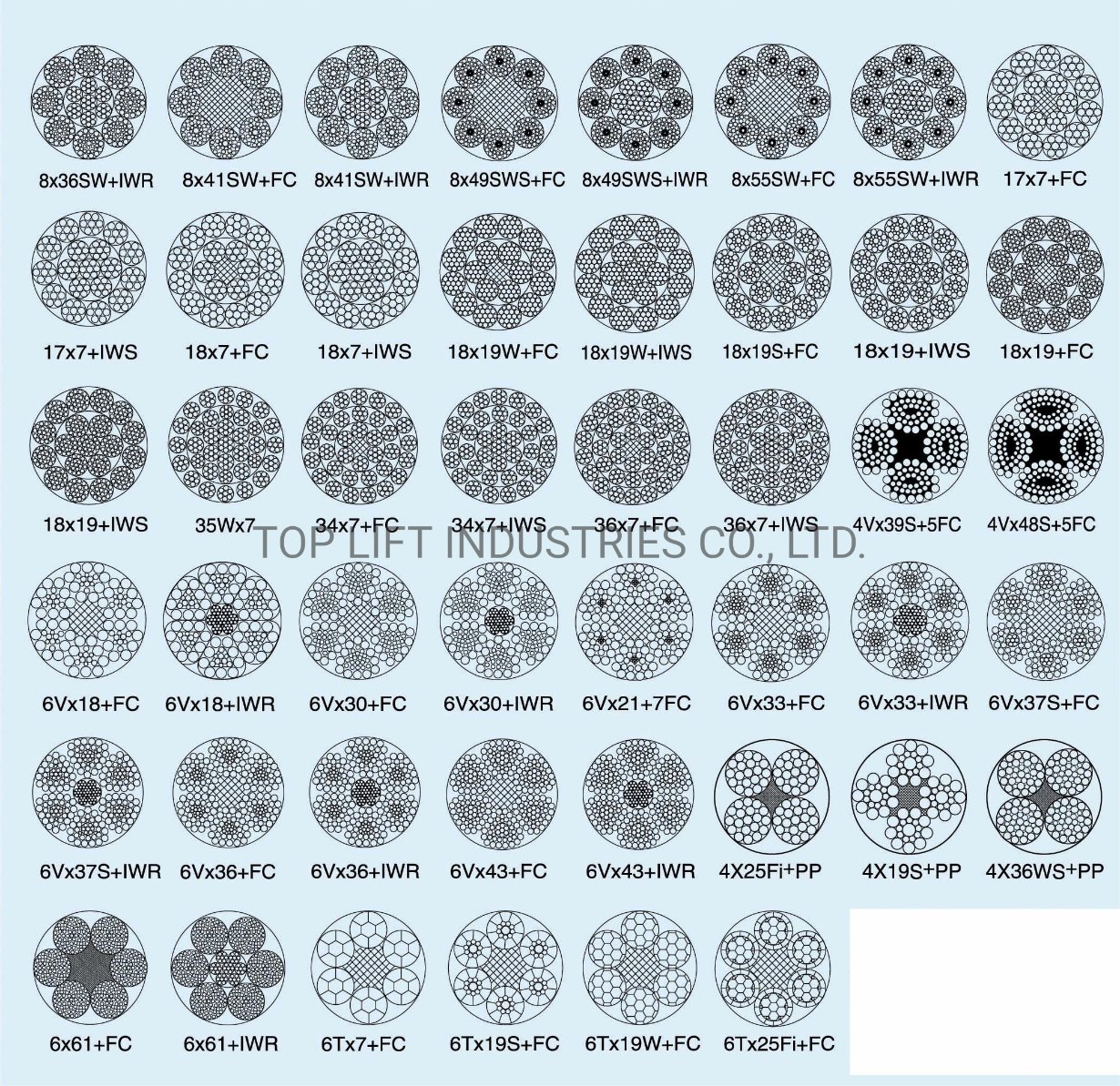

Typical Cross Sections Of Wire Rope&Strand

Production Processing of Wire Rope & Our Workshop

Packing

Wire Rope Accessories. We have much more than you can see

Application

FAQ:

Q1: How to choose the right wire rope?

A1: The following factors need to be considered when choosing a wire rope:

Load carrying capacity (breaking tension and working load of the wire rope)

Environmental conditions (whether there is corrosion, moisture, high temperature, etc.)

Flexibility requirements (number of strands and structure affect flexibility)

Abrasion and fatigue resistance (different braiding methods and materials affect life)

Q2: How to store the wire rope correctly?

A2: Avoid humid environment, store in dry and well ventilated place.

Avoid direct sunlight, prolonged exposure may affect the coating and material performance.

Regularly inspect to ensure no corrosion or damage, and properly apply anti-rust oil.

Q3: How to check if the wire rope needs to be replaced?

A3: Replacement of the wire rope may be required in the following cases:

Wire rope has broken wire (need to be replaced when more than a certain number)

The wire rope is deformed, twisted or knotted

Surface wear is serious or there is obvious corrosion

The structure of the wire rope is loose or the core is damaged

Wire rope is used to increase the support of suspension bridges, elevators, and as an additional reinforcement of towers. The design of wire rope, with its multiple strands wrapped around a stable core, provides strength, flexibility, and ease of handling for applications that have bending stress.

Features:

1. The wire rope can transmit long-distance load.

2. The bearing safety factor is large, and the use is safe and reliable.

3. Light weight, easy to carry and transport.

4. Able to withstand various loads and variable loads.

5. It has high tensile strength, fatigue strength and impact toughness.

6. Under high-speed working conditions, it is abrasion-resistant, shock-resistant and stable in operation.

7. Good corrosion resistance, able to work normally in the harsh environment of various harmful media.

8. Good softness, suitable for traction, pulling, strapping and other purposes.

Technical Parameter

Typical Cross Sections Of Wire Rope&Strand

Production Processing of Wire Rope & Our Workshop

Packing

Wire Rope Accessories. We have much more than you can see

Application

FAQ:

Q1: How to choose the right wire rope?

A1: The following factors need to be considered when choosing a wire rope:

Load carrying capacity (breaking tension and working load of the wire rope)

Environmental conditions (whether there is corrosion, moisture, high temperature, etc.)

Flexibility requirements (number of strands and structure affect flexibility)

Abrasion and fatigue resistance (different braiding methods and materials affect life)

Q2: How to store the wire rope correctly?

A2: Avoid humid environment, store in dry and well ventilated place.

Avoid direct sunlight, prolonged exposure may affect the coating and material performance.

Regularly inspect to ensure no corrosion or damage, and properly apply anti-rust oil.

Q3: How to check if the wire rope needs to be replaced?

A3: Replacement of the wire rope may be required in the following cases:

Wire rope has broken wire (need to be replaced when more than a certain number)

The wire rope is deformed, twisted or knotted

Surface wear is serious or there is obvious corrosion

The structure of the wire rope is loose or the core is damaged