- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

8X61+FC 8X61+IWR

| Availability: | |

|---|---|

| Quantity: | |

Wire rope is employed to enhance the support of suspension bridges, elevators, and to reinforce towers. Its design, featuring multiple strands wound around a central core, offers a combination of strength, flexibility, and ease of handling, making it ideal for applications subject to bending stress.

Basic Info:

| Product Name | steel wire rope | |||

| Raw material | quality carbon steel | |||

| Standard | ISO, DIN, ASTM, GB, etc. | |||

| Construction | 8X61+FC 8X61+IWR | |||

| Features | Steel Cables have smooth surface, high corrosion resistant, high fatigue strength, excellent heat resistance and are free from Lateral / longitudinal cracks, pits and marks etc | |||

| Range of products | (Galvanized, Ungalvanized, coated PVC /PE )steel wire rope Hot dip galvanized steel wire rope, etc | |||

| Packing | plastic wheel, solid wood wheel, plywood wheel, coils, bag, etc | |||

Features:

1. High Strength:

Made from high-strength steel wires, wire ropes have exceptional tensile strength and can withstand significant forces.

2. Abrasion Resistance:

The hard surface of wire ropes makes them highly resistant to wear and tear, suitable for use in harsh environments.

3. Corrosion Resistance:

Wire ropes can be specially treated, such as galvanizing or coating, to enhance their corrosion resistance and extend their service life.

4. Flexibility:

Wire ropes possess good flexibility, allowing them to be easily bent and coiled, facilitating installation and use.

5. Stability:

The structure of wire ropes maintains stability under load, reducing the likelihood of sudden breakage.

6. Even Load Distribution:

Comprised of multiple steel wires, wire ropes can distribute loads evenly, minimizing wear and tear.

7. Durability:

With proper use and maintenance, wire ropes have a long service life.

8. Safety:

Often used for lifting and suspending heavy objects, the high safety factor of wire ropes is a key reason for their selection in many engineering applications.

9. Customizability:

Wire ropes can be customized to meet different application needs, including varying diameters, structures, and materials.

10. Cost-Effectiveness:

Compared to other types of ropes, wire ropes offer a high cost-performance ratio, making them an economical choice.

11. Easy Maintenance:

The maintenance of wire ropes is relatively simple; regular inspection and lubrication ensure smooth operation.

12. Suitable for Various Environments:

Wire ropes can be used in a variety of environmental conditions, including high-temperature, and chemically corrosive settings.

Technical Parameter

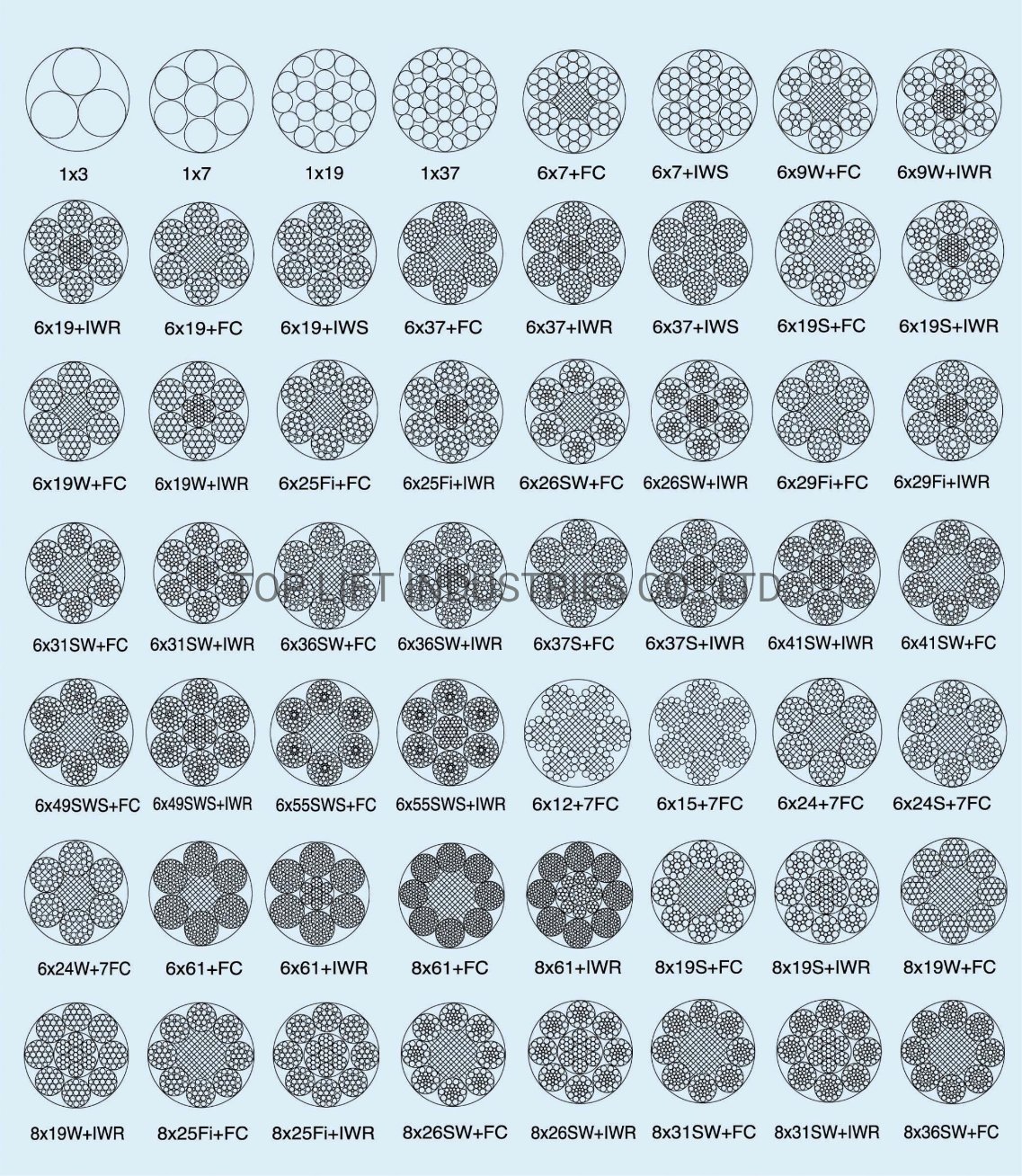

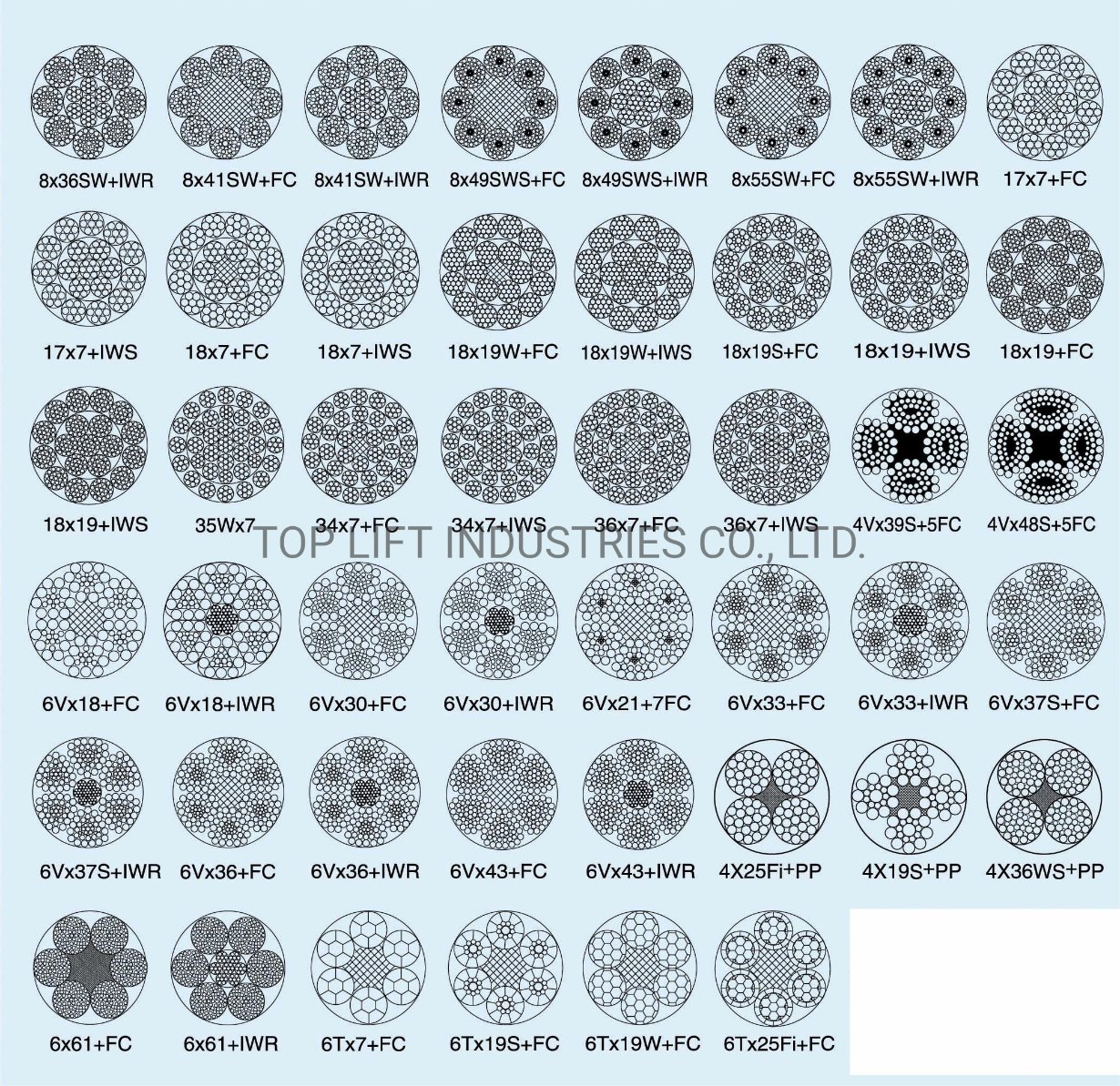

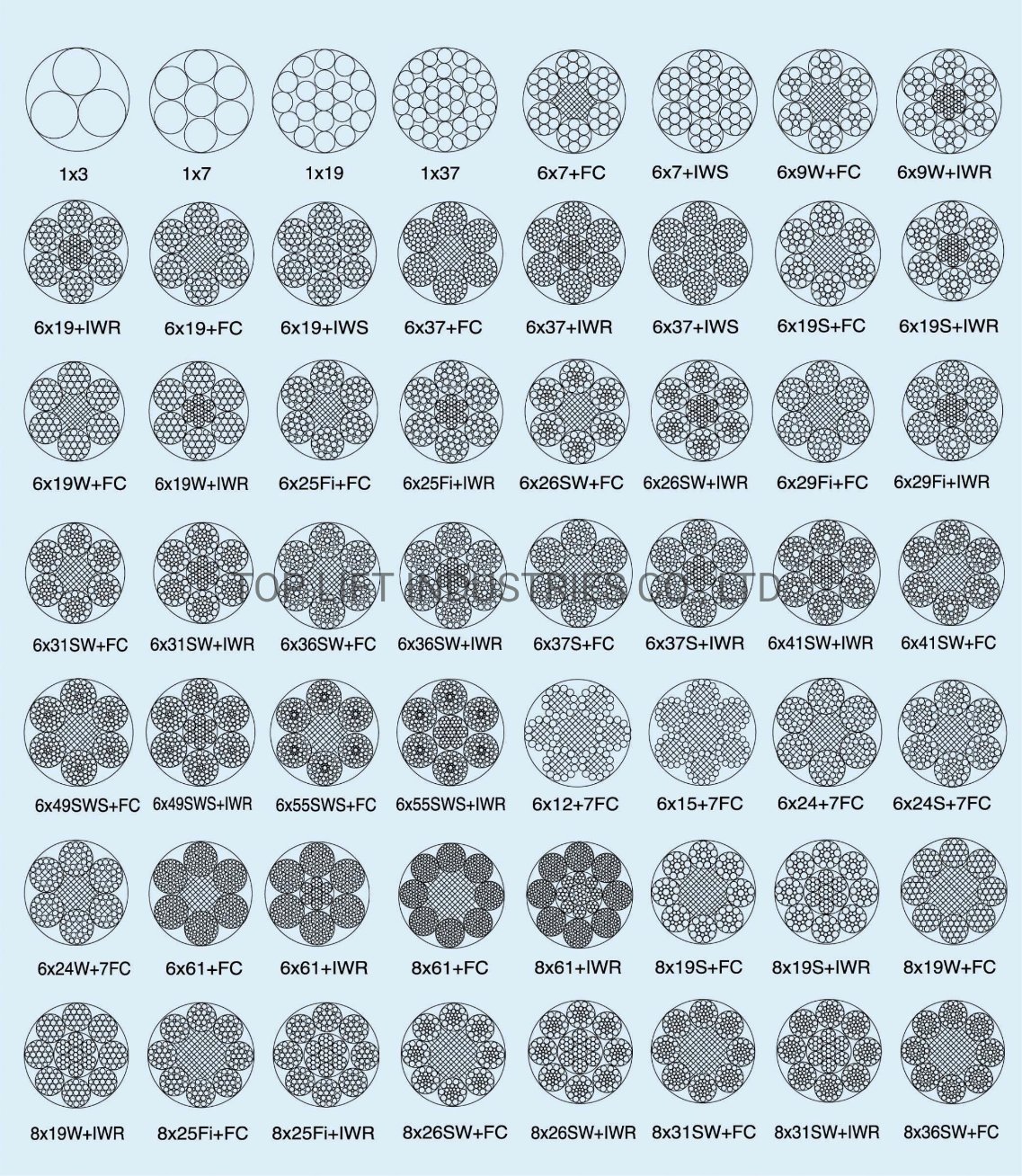

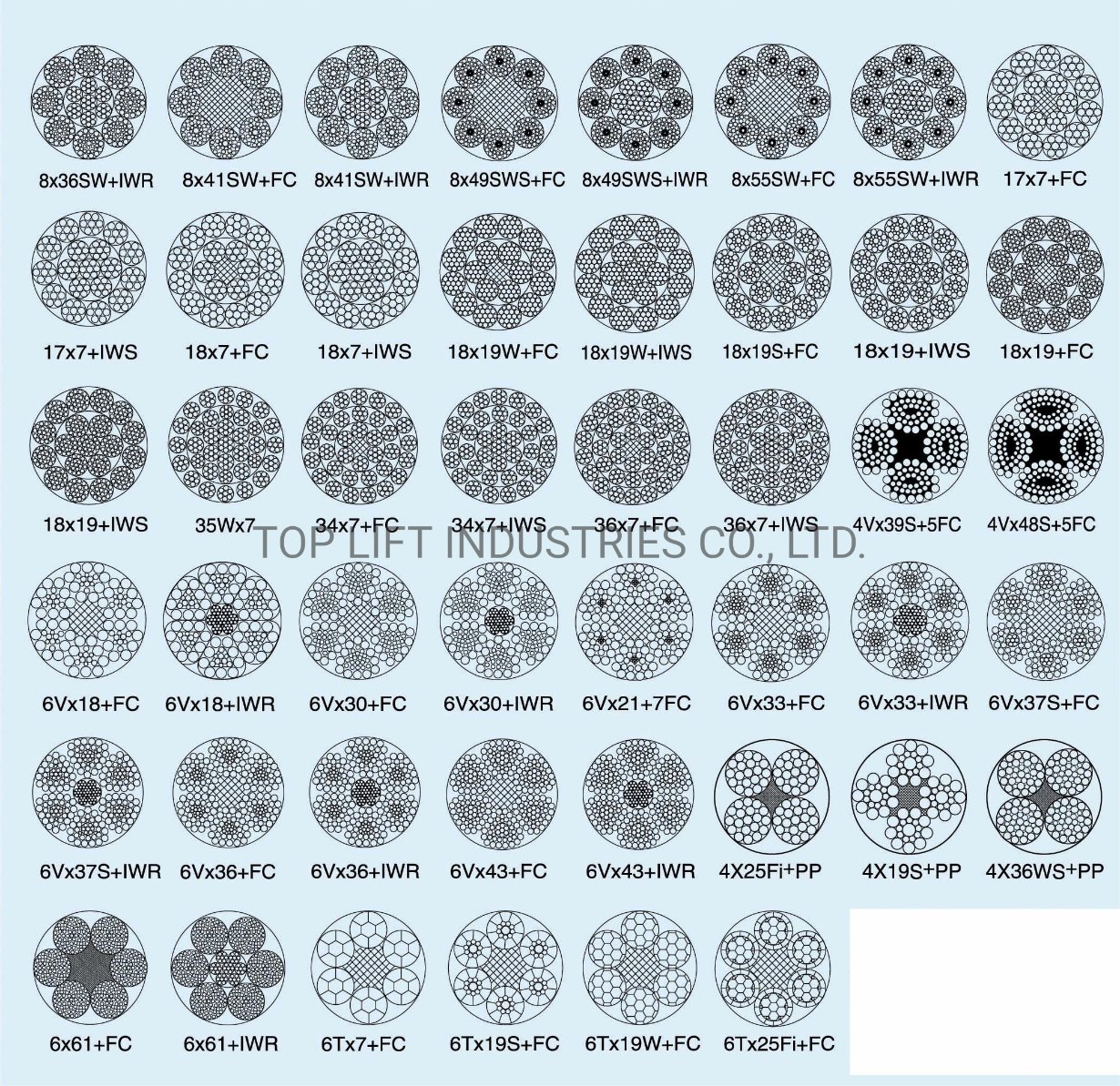

Typical Cross Sections Of Wire Rope&Strand

Production Processing of Wire Rope & Our Workshop

Packing

Wire Rope Accessories. We have much more than you can see

Application

FAQ:

Q: What are your terms of payment?

A: We accept TT, L/C and west union or you can pay through Alibaba. 30%T/T as the upfront deposit, 70% before delivery, We will show you the photos and package before you pay the balance.

Q: Do you have after-sales service?

A: Our quality and service is our life, so even after your buying, we still offer free after sale service.

Q: What's your delivery time?

A: For stocks, we could transport the goods to loading port within 7 work days after we received the deposit. For production period, it usually takes about 30 days to 45 days after we received the deposit.

Q: Could you provide the compliment samples?

A: Yes, we could provide the free samples on condition that it is available in stocks, however,the transportation fee is borne by buyer.

Q6: What product information should I send in my inquiry?

A6: For Steel Wire Rope, pls inform:

1) Structure: such as 1x7, 6x7, 8x19, 6x37, etc.

2) Core: such as fiber core, steel core, etc.

3) Diameter: such as 6mm, 10mm, 20mm, 50mm, etc.

4) Surface treatment: such as Ungalvanized, Electro Galvanized, Hot Dip Galvanized, PVC Coated or Stainless

5) Length per reel: such as 500m/reel, 1000m/reel, etc.

6) Quantity: such as 5000m or 30 reels or 20ton, etc.

Wire rope is employed to enhance the support of suspension bridges, elevators, and to reinforce towers. Its design, featuring multiple strands wound around a central core, offers a combination of strength, flexibility, and ease of handling, making it ideal for applications subject to bending stress.

Basic Info:

| Product Name | steel wire rope | |||

| Raw material | quality carbon steel | |||

| Standard | ISO, DIN, ASTM, GB, etc. | |||

| Construction | 8X61+FC 8X61+IWR | |||

| Features | Steel Cables have smooth surface, high corrosion resistant, high fatigue strength, excellent heat resistance and are free from Lateral / longitudinal cracks, pits and marks etc | |||

| Range of products | (Galvanized, Ungalvanized, coated PVC /PE )steel wire rope Hot dip galvanized steel wire rope, etc | |||

| Packing | plastic wheel, solid wood wheel, plywood wheel, coils, bag, etc | |||

Features:

1. High Strength:

Made from high-strength steel wires, wire ropes have exceptional tensile strength and can withstand significant forces.

2. Abrasion Resistance:

The hard surface of wire ropes makes them highly resistant to wear and tear, suitable for use in harsh environments.

3. Corrosion Resistance:

Wire ropes can be specially treated, such as galvanizing or coating, to enhance their corrosion resistance and extend their service life.

4. Flexibility:

Wire ropes possess good flexibility, allowing them to be easily bent and coiled, facilitating installation and use.

5. Stability:

The structure of wire ropes maintains stability under load, reducing the likelihood of sudden breakage.

6. Even Load Distribution:

Comprised of multiple steel wires, wire ropes can distribute loads evenly, minimizing wear and tear.

7. Durability:

With proper use and maintenance, wire ropes have a long service life.

8. Safety:

Often used for lifting and suspending heavy objects, the high safety factor of wire ropes is a key reason for their selection in many engineering applications.

9. Customizability:

Wire ropes can be customized to meet different application needs, including varying diameters, structures, and materials.

10. Cost-Effectiveness:

Compared to other types of ropes, wire ropes offer a high cost-performance ratio, making them an economical choice.

11. Easy Maintenance:

The maintenance of wire ropes is relatively simple; regular inspection and lubrication ensure smooth operation.

12. Suitable for Various Environments:

Wire ropes can be used in a variety of environmental conditions, including high-temperature, and chemically corrosive settings.

Technical Parameter

Typical Cross Sections Of Wire Rope&Strand

Production Processing of Wire Rope & Our Workshop

Packing

Wire Rope Accessories. We have much more than you can see

Application

FAQ:

Q: What are your terms of payment?

A: We accept TT, L/C and west union or you can pay through Alibaba. 30%T/T as the upfront deposit, 70% before delivery, We will show you the photos and package before you pay the balance.

Q: Do you have after-sales service?

A: Our quality and service is our life, so even after your buying, we still offer free after sale service.

Q: What's your delivery time?

A: For stocks, we could transport the goods to loading port within 7 work days after we received the deposit. For production period, it usually takes about 30 days to 45 days after we received the deposit.

Q: Could you provide the compliment samples?

A: Yes, we could provide the free samples on condition that it is available in stocks, however,the transportation fee is borne by buyer.

Q6: What product information should I send in my inquiry?

A6: For Steel Wire Rope, pls inform:

1) Structure: such as 1x7, 6x7, 8x19, 6x37, etc.

2) Core: such as fiber core, steel core, etc.

3) Diameter: such as 6mm, 10mm, 20mm, 50mm, etc.

4) Surface treatment: such as Ungalvanized, Electro Galvanized, Hot Dip Galvanized, PVC Coated or Stainless

5) Length per reel: such as 500m/reel, 1000m/reel, etc.

6) Quantity: such as 5000m or 30 reels or 20ton, etc.