- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-04 Origin: Site

You use a strong lifting chain with chain hoists. This main part is made from tough alloy steel. It helps lift heavy things in many places. You see it in car repair shops, building sites, and factories. Electric chain hoists move engines and turbines. They also move steel coils very carefully. TOP LIFT Industries sells lifting tools and rigging gear. They also have webbing sling solutions. These products follow global safety rules. You can trust them for hard jobs. They help keep work safe.

Chain hoists use strong chains to lift heavy things. These chains are made from tough alloy steel. This helps keep lifting safe.Certified lifting chains have special designs. They also have safety features. These help stop accidents and make lifting smooth.Picking the right chain grade is important. You also need the right size and coating. This depends on where and how you lift things.Checking and taking care of lifting chains is needed. This keeps your equipment safe. It also helps it last longer.Using certified products from trusted brands like TOP LIFT is smart. It keeps workers safe. It also makes lifting work better.

When you use chain hoists, you rely on a lifting chain to do the heavy work. This chain is not just any chain you find at a hardware store. It is a special type called a load chain, made for lifting heavy objects safely and efficiently. You see these chains in electric, manual, and pneumatic chain hoists.

A lifting chain is made from high-strength alloy steel. This material gives it the power to handle big loads without breaking.

The links are precision-made and heat-treated. This process makes them strong and resistant to wear and fatigue.

Each link fits perfectly with the hoist mechanism. This design helps the chain move smoothly and prevents it from jamming.

Lifting chains have a safety factor of 5:1. This means the chain can handle five times its rated load before it risks breaking.

You cannot swap a lifting chain with a regular chain or a rigging chain. Only use chains made for lifting in your chain hoist.

You will notice that lifting chains are different from other chains, such as those used for slings or for marine applications. For example, stainless steel chains focus on corrosion resistance, but lifting chains focus on strength and durability. TOP LIFT offers a full range of lifting chains, webbing slings, and lifting clamps, all designed for tough jobs.

Tip: Always check for certification markings on your lifting chain. These markings show that the chain meets strict industry standards for safety and performance.

The lifting chain is the most important part of your chain hoist. It carries the full weight of the load and keeps everything balanced and secure. If you choose the wrong chain or use a damaged one, you risk accidents and equipment failure.

The lifting chain supports and moves the load vertically. It connects directly to the hoist mechanism and transmits the lifting force.

High-strength alloy steel construction lets the chain handle heavy stresses and repeated use without stretching or breaking.

The chain’s design ensures it works smoothly with the hoist’s sprocket, reducing the chance of slipping or jamming.

Regular inspection and maintenance are critical. You need to look for signs of wear, rust, or deformation. If you spot any problems, replace the chain right away.

Using a substandard lifting chain can lead to serious risks. These include chain failure, dropped loads, injuries, and costly downtime. Only trust certified chains from reputable suppliers like TOP LIFT.

When you select a lifting chain, you also decide how safe and efficient your lifting operation will be. TOP LIFT’s products meet international standards and go through strict quality checks.

️ Note: Investing in high-quality lifting chains and proper maintenance helps you avoid accidents and keeps your workplace safe.

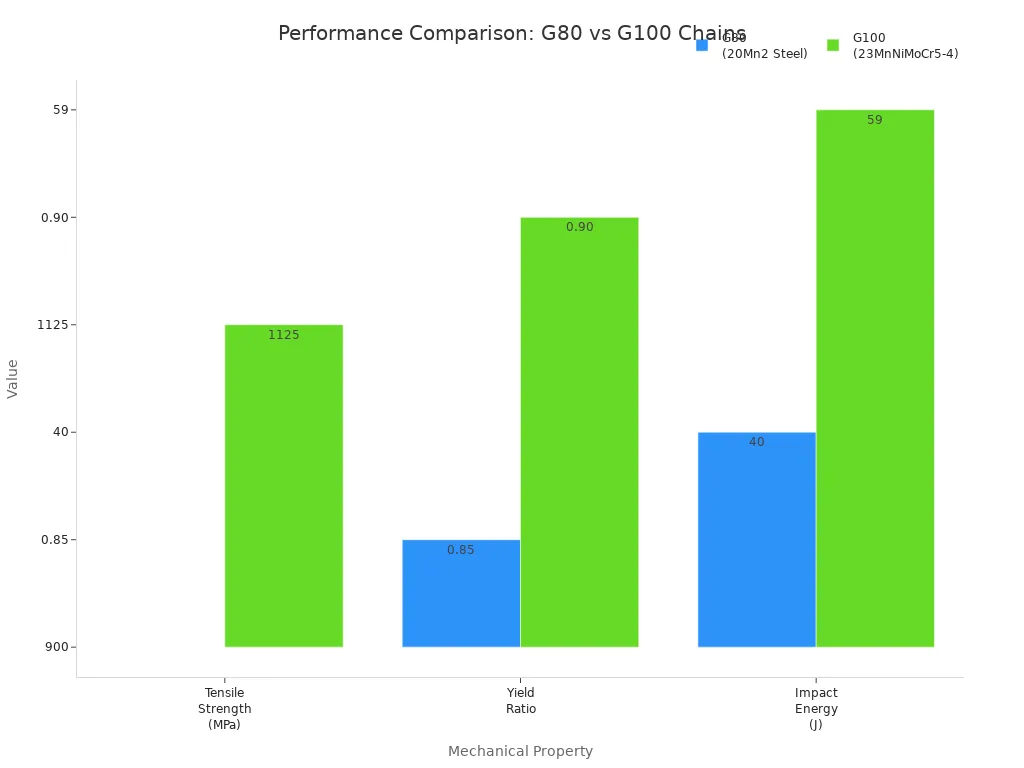

It is important to know what makes a lifting chain strong. Special materials and grades help chains lift heavy things safely. Most load chains for chain hoists use alloy steel. This material gives the chain lots of strength and toughness. G80 and G100 are the most common grades you will see.

Material Type | Chain Grade | Typical Finish | Common Hoist Type | Ideal Usage Environment | Key Advantages |

|---|---|---|---|---|---|

Alloy Steel | G80, G100 | Black paint, phosphate | Manual chain block, electric hoist | Workshops, yards, production lines | High strength, durability, safety factor 4:1 or higher |

Stainless Steel | G80 | Polished only | Manual or motor hoist | Food industry, chemical plants, salt mines, offshore | Corrosion resistance, food-safe |

Zinc-Plated Steel | G80 | 15 µm zinc plating | Lever hoist | Outdoor construction sites | Rust delay with minor weight gain |

Mild Steel (Hand Chain) | N/A | N/A | Hand chain (manual pulling) | Non-load bearing parts | Cost-effective, no full load exposure |

G80 alloy steel chains are used for most lifting jobs. They give a good mix of strength and price. G100 chains are even stronger. They use high-strength low-alloy steel and special heat treatment. This makes them about 25% stronger than G80 chains. You can use G100 chains in harder places, like high heat or where you need more toughness.

You should also think about the finish on your lifting chain. Black paint, phosphate, or zinc plating help stop rust. Stainless steel chains are best for wet or chemical places, like marine or food plants.

Tip: Always pick the right grade and material for your lifting chain. The right chain keeps your lifting safe and easy.

You must follow strict safety rules when using lifting chains. These rules keep you, your team, and your tools safe. International standards like EN 13157, ASME B30.16, and CE certification set the rules for safety and quality. Certified lifting chains go through hard tests, like static and dynamic load tests, checks for wear, and brake tests.

Aspect | Relevant Standards/Certifications | Key Requirements and Details |

|---|---|---|

Material & Components | EN 13157, GB/T 7334-2016 | Chains must be high-strength alloy steel, heat treated; breaking load >4x rated load; hooks made of 35CrMo steel with forging and heat treatment; smooth surfaces; anti-unhooking devices on hooks. |

Design & Manufacturing | EN 13157, GB/T 7334-2016, JB/T 7334-2016 | Structural strength verified by force analysis; safety factors 3-5x rated load; manufacturing process controls with advanced equipment to ensure quality. |

Testing & Inspection | EN 13157, GB/T 7334-2016, ASME B30.16, ASME HST-2 | Static load tests (3-5x rated load), dynamic load tests (lifting/lowering cycles at 1.1x load), fatigue tests, braking performance tests (e.g., ASME B30.16 requires brake to hold 1.25x rated load). |

Product Certification | CE (EU), OSHA & ASME (US) | CE certification for EU market ensuring health, safety, environmental compliance; OSHA and ASME standards compliance and certification for US market. |

Quality Management | ISO 9001:2015 | Quality management system covering raw materials, production, inspection, and after-sales; continuous improvement and employee training emphasized. |

Product Identification | GB/T 7334-2016 | Clear permanent markings with model, rated load, manufacturer info, standard numbers; packaging includes safety instructions. |

TOP LIFT Industries has high standards for safety and quality. You get the benefit of their careful quality checks. Their lab follows ISO/IEC rules and has CNAS approval. Every lifting chain and product, like webbing sling and lifting clamp, gets checked and tested before you get it. TOP LIFT also gives clear markings and safety tips, so you always know how much the chain can lift and how to use it.

TOP LIFT uses modern machines and skilled workers to make sure every chain is top quality.

The company helps you with expert advice before and after you buy.

You can trust TOP LIFT products in tough places, like building sites, ships, and oil fields.

️ Note: Always use certified load chains from trusted brands. Certified chains help you avoid accidents and follow the law and insurance rules.

You use a chain hoist to lift heavy loads with less effort. The gear system is the heart of the lifting mechanism. When you pull the hand chain, the gears inside the hoist start to move. These gears multiply your input force, making it possible to lift weights that would be impossible by hand.

You pull the hand chain.

The gear system converts your manual input into mechanical advantage.

The gears turn a sprocket that grabs the lifting chain.

The lifting chain, made from high-strength alloy steel, fits perfectly into the sprocket’s recesses.

As the sprocket turns, it moves the lifting chain up or down.

The brake system engages automatically when you stop pulling, holding the load securely.

The sprocket works like the gears on a bicycle. It pulls the chain along, lifting or lowering the load. This smooth interaction between the gear system and the lifting chain is what makes chain hoists so reliable.

You find gear systems in manual chain hoists, electric chain hoists, and even pneumatic models. Electric chain hoists use a motor to drive the gears, so you can lift loads with just a button. TOP LIFT offers a wide range of lifting tools, including lifting clamps and webbing slings, that work well with different hoist types.

Mechanical advantage is the secret behind the lifting mechanism in chain hoists. You can lift loads much heavier than your own strength. The system uses gears, pulleys, and chains to multiply your effort.

You pull a hand chain over a longer distance.

The gears and pulleys convert this small force into a much larger lifting force over a shorter distance.

The load chain moves up, raising the heavy object.

A ratchet mechanism keeps the load from slipping back.

The brake system adds safety by holding the load in place.

The mechanical advantage depends on the gear ratio. A higher gear ratio means you need less force to lift a heavier load. Manual chain hoists use a ratchet and pawl system to multiply force. Electric chain hoists use a motor and gear reduction system for even easier lifting. Pneumatic hoists use compressed air and planetary gears for lifting in special environments.

Type of Hoist | Lifting Mechanism | Typical Gear Ratio | Maximum Load Capacity | Best Use Case |

|---|---|---|---|---|

Manual Chain Hoist | Hand chain + gears | High | Up to 20 tons | Workshops, construction |

Electric Chain Hoist | Motor + gear reduction | Very high | Up to 50 tons | Factories, shipyards |

Pneumatic Hoist | Air motor + planetary gears | High | Up to 30 tons | Hazardous, offshore sites |

Mechanical advantage lets you lift engines, steel beams, and machinery safely. You save energy and reduce the risk of injury.

If you want to learn more about lifting mechanisms and related products, visit TOP LIFT’s official product page. You will find lifting clamps, webbing slings, and other solutions for your lifting needs.

You need the right chain hoist and lifting chain for your work. First, check the rated capacity. This tells you the most weight you can lift safely. Think about where you will use the chain hoist. Industrial places need strong chains with tough coatings. Marine and offshore jobs need chains that do not rust, like ones with galvanized or powder coatings. Construction sites need chains that are extra tough and flexible.

Think about these things when picking:

Rated capacity: Make sure the hoist and chain can lift your heaviest load.

Chain grade: Use Grade 80, 100, or 120 for overhead lifting. Lower grades are not safe for heavy things.

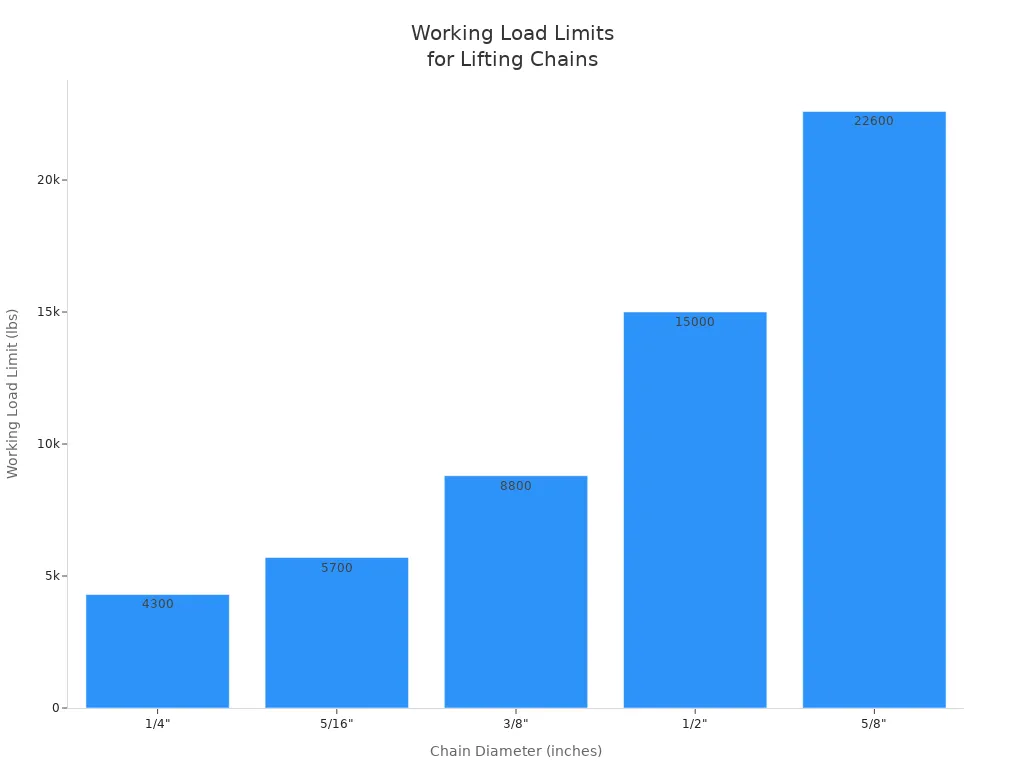

Chain diameter: Thicker chains can lift more weight. Look at the table below for working load limits.

Chain Diameter | Approximate Size (inches) | Working Load Limit (lbs) |

|---|---|---|

1/4" | ~0.29 | 4,300 |

5/16" | ~0.33 | 5,700 |

3/8" | ~0.39 | 8,800 |

1/2" | ~0.53 | 15,000 |

5/8" | ~0.64 | 22,600 |

Hoist type: Manual chain hoists are good for light or rare lifting. Electric chain hoists are better for heavy, frequent, or careful lifting. Electric hoists are faster and more accurate.

Environmental conditions: Pick chains with special coatings for places with lots of rust or heat.

Customization: TOP LIFT can make chains in special lengths, coatings, and lifting clamps for you.

️ Tip: Always look for certification marks and clear tags. These show the chain is safe to use.

You keep your lifting tools safe by doing regular maintenance. Check chains before every use. Look for bent, cracked, stretched, or twisted links. Take out any damaged links right away. Clean chains to find hidden damage and stop rust. Lubricate chains with special oil to cut down wear and help them move smoothly.

Follow these steps for best results:

Check chain links for wear, rust, or bending.

Look at hooks, rings, and attachments for loose parts.

Make sure you can read the working load limit and maker’s details.

Clean and oil chains after use, especially in wet or salty places.

Store chains in dry, safe spots.

Teach workers how to handle chains safely and spot damage early.

Replace chains that are very worn or rusty.

Industry rules say you should look at chains every day and do full checks sometimes. Write down all your inspections. Take chains out of use if you see cracks, too much wear, or if you cannot read the tags.

⚠️ Note: If you skip maintenance, chains can break, cause accidents, and stop work. Taking care of your electric chain hoists and other lifting tools helps them last longer.

TOP LIFT has many lifting chains, electric hoists, webbing slings, and lifting clamps. Their products follow world safety rules and can be made for different jobs.

Picking the right lifting chain for your chain hoist is important. It helps keep your team safe and makes work go smoothly. You can stop accidents by following safety rules and checking your tools often.

Certified lifting chains from trusted brands like TOP LIFT Industries are strong and last a long time. You also get help from experts.

Checking your chains, teaching workers the right way, and using things like webbing slings or lifting clamps can stop problems and save time.

️ Always use certified lifting chains and follow safety rules. Doing this keeps your people and your business safe.

A lifting chain uses high-grade alloy steel and meets strict safety standards. You should never use a regular chain for lifting. Only certified lifting chains can handle heavy loads safely in chain hoists.

You should inspect your lifting chain before every use. Look for wear, rust, or damage. Schedule a full inspection every few months. Regular checks help you prevent accidents and keep your lifting chain safe.

You can use chain hoists in many places, but you must choose the right type. For marine or chemical areas, pick chains with special coatings. For construction, use tough, durable chains. TOP LIFT offers options for every environment.

You can use webbing slings, lifting clamps, and shackles with your chain hoist. These tools help you move loads safely and easily. Visit the TOP LIFT product page to see more lifting solutions.

You can buy certified lifting chains, electric chain hoists, and related accessories directly from TOP LIFT. Their products meet international safety standards. Contact their team for expert advice and custom solutions for your lifting needs.