- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

As a professional China-based manufacturer, TOP LIFT INDUSTRIES CO., LIMITED specializes in producing high-performance Galvanized Steel Stud Link Anchor Chain—a core product designed for marine anchoring systems, offshore operations, and industrial lifting scenarios. With an annual production capacity of 20,000 tons, advanced manufacturing technology, and strict quality control, our anchor chain meets global standards and caters to both standard and customized needs. Below is a detailed breakdown of its key attributes, from appearance to compliance.

| Availability: | |

|---|---|

| Quantity: | |

The appearance of our Galvanized Steel Stud Link Anchor Chain is engineered for both functionality and long-term reliability, with every detail optimized for harsh environments like saltwater or heavy industrial use.

All our anchor chains feature a galvanized surface treatment—a critical design choice that delivers exceptional anti-corrosion and anti-rust performance. The galvanized layer is evenly applied through a professional process, ensuring no gaps or thin spots that could lead to premature wear. This coating acts as a barrier against moisture, salt spray, and chemical exposure, making the chain ideal for marine applications where rust is a major concern. Unlike ordinary paint coatings, galvanization bonds with the steel substrate, providing long-lasting protection even in high-humidity or high-temperature conditions (a key advantage for offshore oil & gas or coastal construction projects).

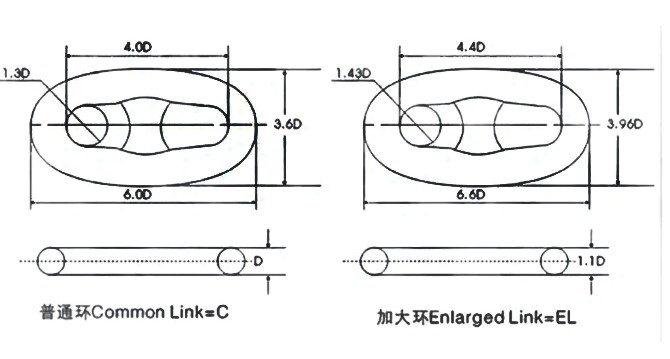

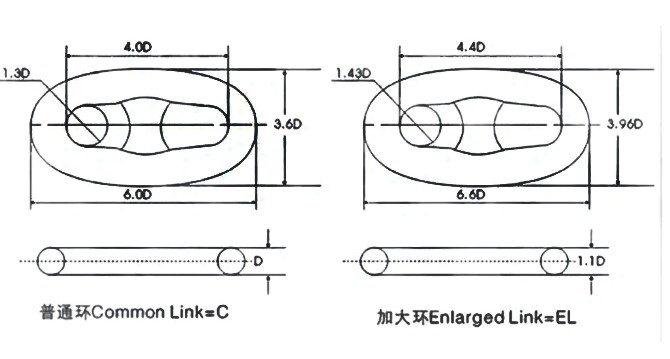

Our Galvanized Steel Stud Link Anchor Chain is available in a wide dimensional range: from 14mm to 127mm in diameter. This flexibility allows it to adapt to small vessels, large cargo ships, and industrial lifting equipment alike. Visually, each chain link boasts uniform size and smooth edges—no burrs or uneven welds—thanks to our precision manufacturing tools. The "stud link" structure (a raised bar inside each link) is clearly visible and consistently shaped, a hallmark of our strict quality control. When stacked or deployed, the chains maintain a neat, stable form, reducing the risk of tangling during use.

The mechanism design of our Stud Link Anchor Chain focuses on two core goals: maximum load-bearing capacity and resistance to deformation. Every design element is backed by advanced technology and rigorous testing.

The defining feature of our anchor chain is its stud link design—a central stud (or bar) inside each link that prevents the chain from stretching or deforming under heavy loads. This structure distributes weight evenly across the entire link, rather than concentrating stress on specific points. For example, when used to anchor a large ship, the stud link ensures the chain can withstand the pull of waves and currents without bending or breaking. Compared to studless chains, our stud link model offers enhanced structural stability (tested via in-house tensile testing equipment), making it suitable for high-load scenarios like marine anchoring or industrial lifting.

To ensure the chain’s durability, we use full-automatic flash butt welding—a state-of-the-art process that creates strong, seamless joints between links. This welding method eliminates weak points often found in manual welding, such as air bubbles or incomplete fusion. After welding, each chain undergoes quenching and tempering (a heat treatment process) to enhance its hardness and toughness. This step ensures the chain can resist high temperatures (critical for industrial environments) and sudden impacts, such as when an anchor is dropped quickly. Our manufacturing line is also equipped with matching heat treatment and tensile testing equipment, allowing us to inspect every batch of chains for strength and compliance before delivery.

Our Galvanized Steel Stud Link Anchor Chain adheres to international and national standards, with all standard parts designed for compatibility and consistency. This ensures our product integrates seamlessly with existing marine or industrial systems.

We strictly execute two key standards: ISO 1704 (the international standard for anchor chains) and GB 549-2008 (China’s national standard for marine anchor chains). These standards govern every aspect of production, from material selection (high-quality steel) to dimensional accuracy and load-bearing capacity. Compliance with these norms means our chain meets the requirements of global markets—whether you’re importing for European, American, or Asian projects. Additionally, our product is classified under HS Code 73158100, simplifying customs clearance for international shipments.

While the core of our product is the Galvanized Steel Stud Link Anchor Chain itself, we also offer compatible standard parts to support full system integration. These include:

• Anchor Chain Connectors: As seen in our related products (e.g., "U2 Anchor Chain Two Anchor Chains Connector"), these standard parts allow easy linking of multiple chains, ensuring a secure connection that matches the chain’s load capacity.

• Testing & Inspection Tools: Every chain is accompanied by standard quality certificates, verifying its compliance with ISO 1704 and GB 549-2008. Our in-house tensile testing equipment—part of our standard production process—ensures each chain meets or exceeds load requirements.

For customers with specific needs, we also provide OEM services (having supported over 30 global brands to date). This includes customizing standard parts like connectors or adjusting chain dimensions (within 14mm-127mm) to fit unique applications, all while maintaining compliance with international standards.

Our Galvanized Steel Stud Link Anchor Chain combines durable galvanized coating, stable stud link design, and global standard compliance—making it a reliable choice for marine, offshore, and industrial use. With an annual capacity of 20,000 tons, we can fulfill both large orders and small trial batches (MOQ varies by product; contact us for details). Whether you need a standard chain or a customized solution, our team ensures quality from production to delivery.

Surface Treatment | Galvanized | Trademark | TOPLIFT or OEM | |

Type | Stud Anchor Chain | Origin | China | |

Transport Package | in Bulk | HS Code | 73158100 | |

Specification | Dia 14mm-127mm | Production Capacity | 20000 tons/year |

The appearance of our Galvanized Steel Stud Link Anchor Chain is engineered for both functionality and long-term reliability, with every detail optimized for harsh environments like saltwater or heavy industrial use.

All our anchor chains feature a galvanized surface treatment—a critical design choice that delivers exceptional anti-corrosion and anti-rust performance. The galvanized layer is evenly applied through a professional process, ensuring no gaps or thin spots that could lead to premature wear. This coating acts as a barrier against moisture, salt spray, and chemical exposure, making the chain ideal for marine applications where rust is a major concern. Unlike ordinary paint coatings, galvanization bonds with the steel substrate, providing long-lasting protection even in high-humidity or high-temperature conditions (a key advantage for offshore oil & gas or coastal construction projects).

Our Galvanized Steel Stud Link Anchor Chain is available in a wide dimensional range: from 14mm to 127mm in diameter. This flexibility allows it to adapt to small vessels, large cargo ships, and industrial lifting equipment alike. Visually, each chain link boasts uniform size and smooth edges—no burrs or uneven welds—thanks to our precision manufacturing tools. The "stud link" structure (a raised bar inside each link) is clearly visible and consistently shaped, a hallmark of our strict quality control. When stacked or deployed, the chains maintain a neat, stable form, reducing the risk of tangling during use.

The mechanism design of our Stud Link Anchor Chain focuses on two core goals: maximum load-bearing capacity and resistance to deformation. Every design element is backed by advanced technology and rigorous testing.

The defining feature of our anchor chain is its stud link design—a central stud (or bar) inside each link that prevents the chain from stretching or deforming under heavy loads. This structure distributes weight evenly across the entire link, rather than concentrating stress on specific points. For example, when used to anchor a large ship, the stud link ensures the chain can withstand the pull of waves and currents without bending or breaking. Compared to studless chains, our stud link model offers enhanced structural stability (tested via in-house tensile testing equipment), making it suitable for high-load scenarios like marine anchoring or industrial lifting.

To ensure the chain’s durability, we use full-automatic flash butt welding—a state-of-the-art process that creates strong, seamless joints between links. This welding method eliminates weak points often found in manual welding, such as air bubbles or incomplete fusion. After welding, each chain undergoes quenching and tempering (a heat treatment process) to enhance its hardness and toughness. This step ensures the chain can resist high temperatures (critical for industrial environments) and sudden impacts, such as when an anchor is dropped quickly. Our manufacturing line is also equipped with matching heat treatment and tensile testing equipment, allowing us to inspect every batch of chains for strength and compliance before delivery.

Our Galvanized Steel Stud Link Anchor Chain adheres to international and national standards, with all standard parts designed for compatibility and consistency. This ensures our product integrates seamlessly with existing marine or industrial systems.

We strictly execute two key standards: ISO 1704 (the international standard for anchor chains) and GB 549-2008 (China’s national standard for marine anchor chains). These standards govern every aspect of production, from material selection (high-quality steel) to dimensional accuracy and load-bearing capacity. Compliance with these norms means our chain meets the requirements of global markets—whether you’re importing for European, American, or Asian projects. Additionally, our product is classified under HS Code 73158100, simplifying customs clearance for international shipments.

While the core of our product is the Galvanized Steel Stud Link Anchor Chain itself, we also offer compatible standard parts to support full system integration. These include:

• Anchor Chain Connectors: As seen in our related products (e.g., "U2 Anchor Chain Two Anchor Chains Connector"), these standard parts allow easy linking of multiple chains, ensuring a secure connection that matches the chain’s load capacity.

• Testing & Inspection Tools: Every chain is accompanied by standard quality certificates, verifying its compliance with ISO 1704 and GB 549-2008. Our in-house tensile testing equipment—part of our standard production process—ensures each chain meets or exceeds load requirements.

For customers with specific needs, we also provide OEM services (having supported over 30 global brands to date). This includes customizing standard parts like connectors or adjusting chain dimensions (within 14mm-127mm) to fit unique applications, all while maintaining compliance with international standards.

Our Galvanized Steel Stud Link Anchor Chain combines durable galvanized coating, stable stud link design, and global standard compliance—making it a reliable choice for marine, offshore, and industrial use. With an annual capacity of 20,000 tons, we can fulfill both large orders and small trial batches (MOQ varies by product; contact us for details). Whether you need a standard chain or a customized solution, our team ensures quality from production to delivery.

Surface Treatment | Galvanized | Trademark | TOPLIFT or OEM | |

Type | Stud Anchor Chain | Origin | China | |

Transport Package | in Bulk | HS Code | 73158100 | |

Specification | Dia 14mm-127mm | Production Capacity | 20000 tons/year |